GTRONTEC Debuts at 2025 China Semiconductor Advanced Packaging and Testing Conference, Empowering CIM Autonomy with AI

On October 22, the 2025 China Semiconductor Advanced Packaging Conference and China Semiconductor Wafer Manufacturing Conference were grandly held in Kunshan, Jiangsu. The conference centered on the core theme 'Wafer manufacturing is the foundation, advanced packaging is the breakthrough direction,' gathering experts, scholars, enterprise leaders, and high-level representatives from industry, academia, research, and application in the global semiconductor field to jointly discuss industry technical bottlenecks and collaborative development paths. As a leading enterprise in semiconductor industrial intelligence, Yang Jun, head of GTRONTEC's advanced packaging and testing business line, was invited to attend and deliver a keynote speech titled 'From Automation to Autonomy: The New Generation Evolution Path of AI-Empowered Advanced Packaging CIM,' systematically elaborating on the practical path and implementation results of AI-empowered advanced packaging CIM, and fully unveiling the core architecture of the advanced packaging CIM solution in the exhibition area. During the event, the company won the 'Advanced Packaging Outstanding Contribution Award' for its innovative AI+CIM+AMHS architecture, highlighting its benchmark role in promoting the semiconductor intelligence process.

Yang Jun pointed out that the semiconductor industry is currently facing multiple challenges such as AI chip computing power iteration, involution competition, geopolitics, and rising quality requirements, and advanced packaging has become a core battlefield for integrating front-end and back-end processes, requiring AI technology to drive the evolution of CIM systems from 'experience-dependent' to 'autonomous decision-making.' Helping customers streamline processes, conduct complex advanced analysis based on digital tools, and provide intelligent means for improved decision-making has become a key capability to assist customers in achieving digital operations and decision automation for advanced packaging CIM.

Addressing real-world demands, Yang Jun combined GTRONTEC's practical experience in serving TCL's intelligent manufacturing transformation and used the 'Three Transformations and Four Steps' methodology to unveil the implementation path for digital operations and decision automation in advanced packaging CIM. Yang Jun emphasized building on lean, automation, and informatization as the foundation, integrating AI technology into the four stages of data connectivity, business process informatization, actionable digital operations, and intelligent data insights, gradually achieving autonomous decision-making capabilities for CIM systems. He specifically mentioned that the bottleneck in enterprise intelligent transformation is not a lack of technology but deficiencies in methodology and collaboration. To support this point, Yang Jun shared GTRONTEC's practical case at a wafer enterprise, where GTRONTEC used the AI-FDC system to monitor 54 process parameters of CMP equipment from different suppliers in real-time, providing early warnings for faults like filter blockages and wafer breakages, significantly reducing quality losses. Additionally, the RTS real-time scheduling system deployed at a customer's Yixing factory optimized machine operation schedules, successfully reducing unplanned downtime by 50%, with annual benefits reaching millions of yuan. These cases clearly demonstrate the practical value of AI technology in improving yield and efficiency.

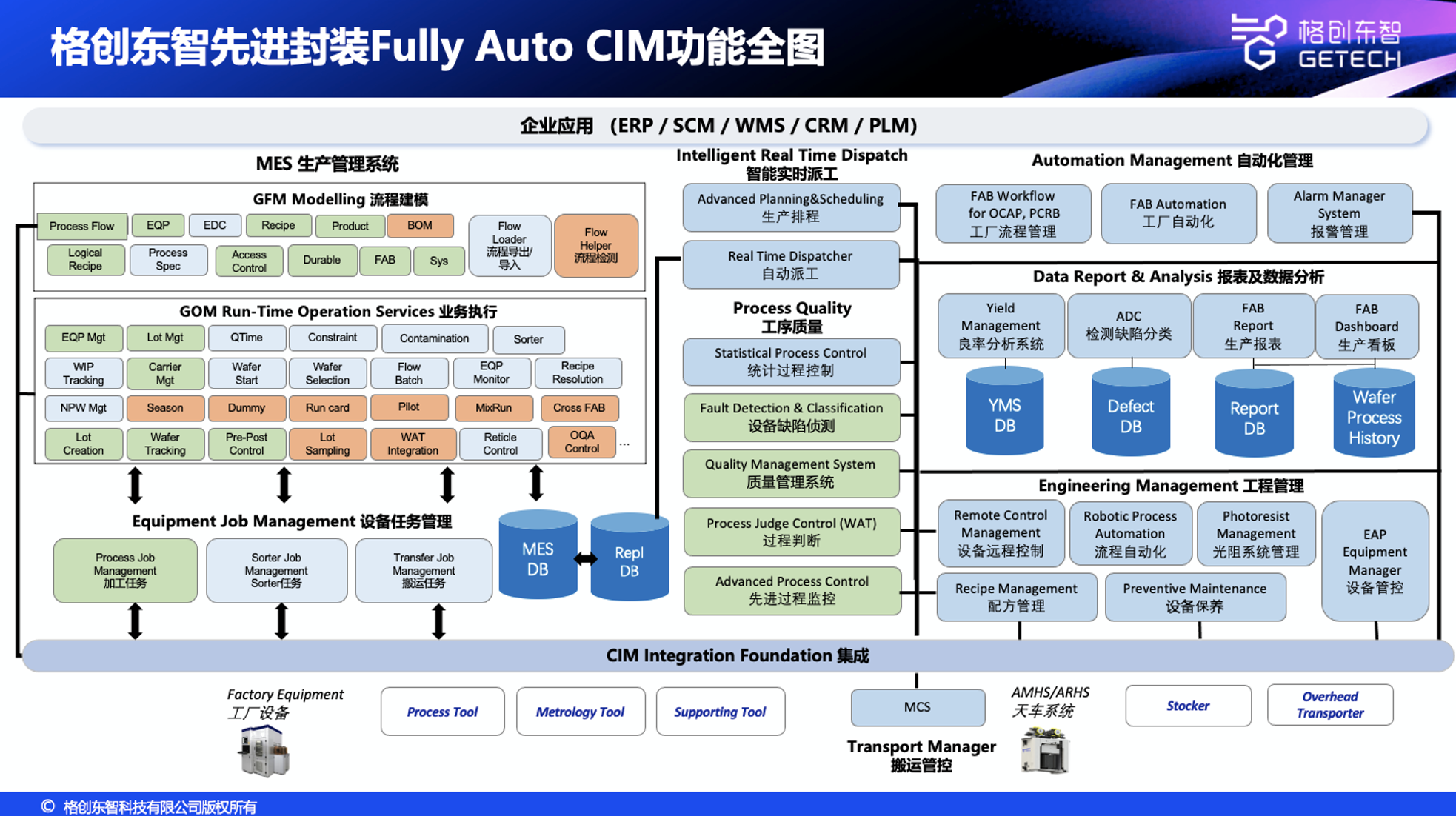

GTRONTEC has always regarded the semiconductor industry as a strategic focus, empowering semiconductor customers with 'AI+CIM+AMHS' to meet digital demands for extreme efficiency, extreme yield, and extreme cost. At the technical implementation level, GTRONTEC uses AI to reconstruct semiconductor CIM and has launched a new generation of advanced packaging and testing CIM solutions covering core modules such as production, equipment, quality, and logistics. Its AI-MES supports full lifecycle traceability at the die level, AI-FDC supports predictive maintenance for equipment processes, AI-EAP enables equipment interconnection and recipe management, AI-QMS breaks through on-site quality management boundaries, supporting full lifecycle control from R&D to after-sales, while the AI-AMHS automated material handling system dynamically optimizes logistics paths through AI algorithms and smart equipment, driving factory Fully Auto implementation. Yang Jun emphasized that GTRONTEC, based on the 'ABCDE—Algorithm, Business, Data, Computing, Equipment' industrial AI application implementation architecture, provides factories with closed-loop support from perception to decision-making, helping customers build AI competitiveness.

During the conference, GTRONTEC won the 'Advanced Packaging Outstanding Contribution Award' granted by the conference for its four major advantages: full-scenario coverage, 70%+ pre-configured functions, CIM+AMHS linkage, and large model and Agent support, as well as outstanding achievements including over 30 patents, not only reflecting its technical leadership but also highlighting the industry's urgent need for autonomous advanced packaging CIM solutions.

Meanwhile, GTRONTEC's booth became a hotspot for technical exchange. The exhibition area centrally displayed its advanced packaging Fully Auto CIM solution, including AI-driven production command centers, equipment intelligent operation and maintenance systems, and closed-loop quality management innovative scenario applications. Among them, the production command center AI-MES supports fine-grained full lifecycle management, intelligent batch and carrier management, and multi-source Map integration management, attracting inquiries and discussions from technical representatives of hundreds of enterprises.

From an industry perspective, GTRONTEC's practices provide a reusable path reference for the intelligent upgrade of the semiconductor industry. Its solutions deeply integrate AI with manufacturing processes, helping enterprises move from 'point automation' to 'global autonomy,' responding to national intelligent manufacturing maturity capability building requirements. As the only industrial intelligence enterprise in China's semiconductor field with full-stack AI+CIM+AMHS solution capabilities, GTRONTEC is accelerating the transformation of China's semiconductor industry from 'catching up' to 'running alongside' through continuous technological innovation and empowerment.