GTRONTEC New Generation Semiconductor Advanced Packaging and Testing CIM Solution: Empowering Advanced Packaging, Moving Towards 'Lights-Out Factory'

In the 'Post-Moore Era', advanced packaging technology has become a key path to improve chip performance, integration, and cost-effectiveness. Facing new challenges from complex processes like 2.5D/3D integration, wafer-level packaging (WLP), and system-in-package (SiP) on manufacturing management, the 'brain' of the manufacturing system—the CIM system—urgently needs iteration.

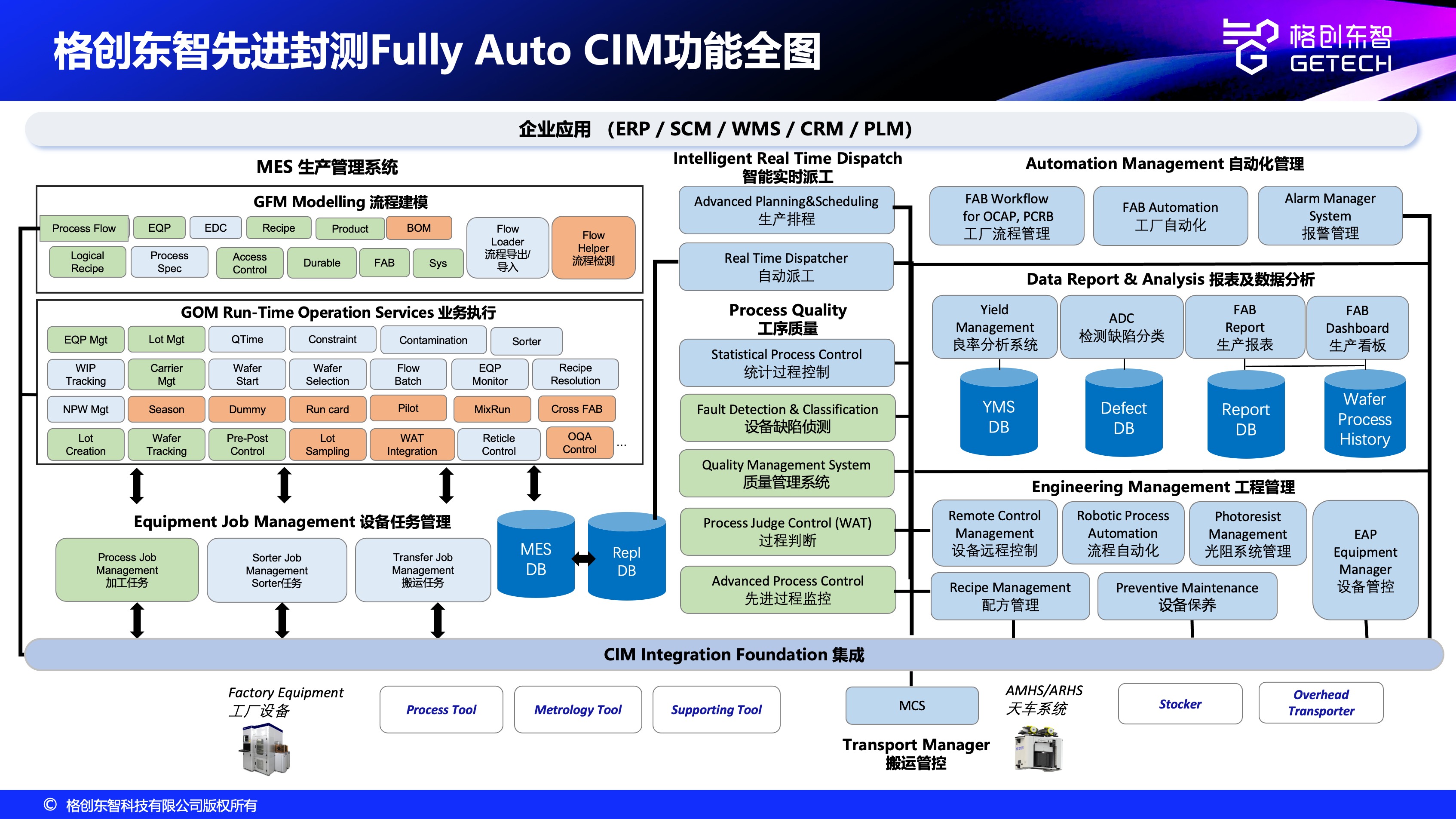

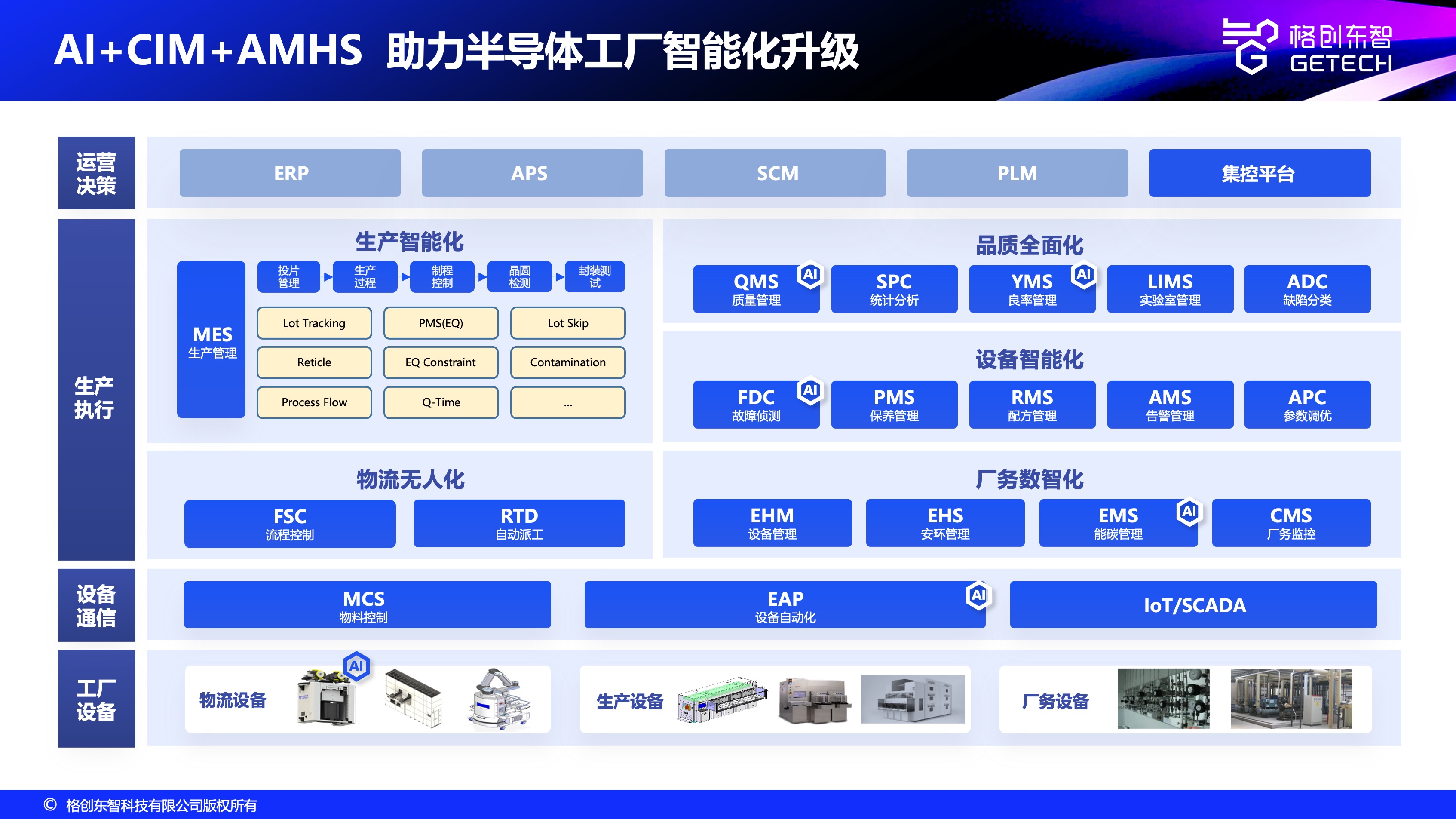

GTRONTEC, based on deep semiconductor industry know-how and cutting-edge technology practices, launches a new generation advanced packaging and testing CIM solution. Through deep integration of 'informationization + automation', it connects data from production, equipment, quality, logistics, etc., helping advanced packaging and testing factories achieve efficient operation and intelligent upgrade.

1. Why Does Advanced Packaging and Testing Need a Dedicated CIM Solution?

Advanced packaging and testing is not simple back-end processing, but a highly complex process integrating wafer manufacturing and system assembly. Its core management difficulties are mainly reflected in four aspects, which traditional CIM systems struggle to adapt to.

Management granularity: From 'batch' to 'die'. Traditional batch management cannot meet the full lifecycle traceability requirements of individual dies for processes like CoWoS and FO-WLP.

Non-linear processes: Heterogeneous integration and restructuring become common. Processes like TSV, micro-bumps, and multi-chip stacking bring numerous branches, rework, and engineering changes, requiring high process flexibility in the system.

Data traceability: Need to achieve full-chain forward and reverse precise traceability. When final testing detects defects, it must quickly reverse-locate to the original wafer, CP data, and each processing step.

Automation depth: From 'human-machine collaboration' to 'lights-out factory'. Moving towards a 'lights-out factory' requires deep integration of the CIM system with OHT, Stocker, etc., to achieve autonomous decision-making and execution across the entire production process.

2. Full-Stack Core Capabilities of the New Generation Advanced Packaging and Testing CIM Solution

Addressing the above challenges, GTRONTEC's new generation advanced packaging and testing CIM solution builds core capabilities around five modules: production, equipment, quality, automation, and visualization, achieving data-driven global collaboration and intelligent decision-making.

1. Production Command Center (G-MES): Achieving Full-Process Refined Control

As the command center of the CIM system, G-MES provides key capabilities for the specifics of advanced packaging and testing:

Die-level full lifecycle traceability: Through the E-Mapping system, accurately track the origin and path of each die in complex scenarios involving multiple reorganizations and stacking.

Intelligent batch and carrier management: Supports complex split/merge rules, bank management, and carrier status control to handle frequent material reorganization needs.

Multi-source Map integrated management: Seamlessly integrates CP (wafer probe test), FT (final test), AOI (automatic optical inspection) data, achieving overlay, comparison, and dynamic updates of Wafer/Strip Maps, accurately guiding sorting and bonding.

Rule-based intelligent control: Automatically triggers production actions based on preset rules (e.g., Q-Time, equipment constraints), enabling intelligent process control.

2. Equipment Intelligent Operation and Maintenance System (EAP+FDC+RMS): Ensuring Stability and Efficiency

EAP (Equipment Automation System): Possesses strong equipment connectivity, supports protocols like SECS/GEM, quickly interfaces with various domestic and international packaging and testing equipment, achieving automatic data collection, remote control, and status monitoring.

FDC (Fault Detection and Classification System): Real-time collection of equipment process parameters, uses model algorithms for anomaly detection, provides early warnings for potential faults, reducing product scrap.

RMS (Recipe Management System): Centrally manages equipment recipes, achieves version control and golden recipe distribution, ensuring process consistency and preventing parameter misoperation.

3. Closed-Loop Quality Management (QMS+ SPC+OCAP): Safeguarding Yield

QMS (Quality Management System): Extends quality management from internal production to the supply chain, achieving full lifecycle quality control from supplier access, incoming inspection, in-process quality monitoring to customer feedback, building a complete quality knowledge base.

SPC (Statistical Process Control System) & OCAP (Out-of-Control Action Plan): Real-time monitoring of key process parameters, automatically triggers OCAP upon anomalies, standardizing problem handling processes and shortening response time.

4. Automation Management: Moving Towards 'Lights-Out Factory' in Three Stages

In this process, the CIM system will deeply integrate with MCS, AMHS, and other systems to achieve full-process automatic reservation, automatic transport, automatic processing, and automatic decision-making.

Stage 1: Informationized Factory (Auto1). Focuses on building core systems (MES/EAP/SPC, etc.), achieving basic information management for production, equipment, quality, etc.

Stage 2: Dark Factory (Auto2). Introduces AMR/OHT automatic transport, Stocker automatic storage, RTD real-time dispatch, etc., achieving high automation in material handling and storage.

Stage 3: Lights-Out Factory (Auto3). Deeply integrates AI applications, such as process robots, digital twins, etc., achieving full-process automatic decision-making and unmanned operation.

5. Full-Scenario Visualization (Data Dashboard + FMB Kanban): Achieving Transparent Operation

Management War Room: Through data dashboards, real-time control of key indicators like capacity, yield, equipment utilization, assisting decision-making.

Workshop Monitoring Center: FMB kanban displays machine status, WIP dynamics, anomaly alerts in real-time, supporting flexible multi-screen combinations.

Mobile Collaboration: Supports access to key information anytime, anywhere via mobile/tablet, enabling mobile office and quick response.

3. Highlights of GTRONTEC's Advanced Packaging and Testing CIM Solution

Compared to traditional CIM solutions, GTRONTEC's solution has four unique advantages, precisely matching advanced packaging needs:

Full-Scenario Coverage, Seamlessly Connecting Front and Back-End Processes

One system integrates front-end process management (e.g., TSV, RDL) and back-end packaging and testing (e.g., bonding, FT) full processes, breaking data silos. No need to switch between multiple systems; manage all steps from wafer inbound to finished product outbound through G-MES, improving overall factory operation efficiency.

70%+ Pre-configured Functions, Efficiently Adapting to Advanced Packaging Processes

Built-in over 70% out-of-the-box functions, covering 23 core advanced packaging process scenarios like WLP, TSV 2.5D/3D IC, Chiplet, significantly shortening system deployment cycles, solving the industry pain point of fast technology iteration and difficult adaptation in advanced packaging.

CIM+AMHS Integration, Accelerating Full Auto Upgrade

GTRONTEC is the only company in the industry that can simultaneously provide 'AI+CIM+AMHS' integrated hardware-software solutions, deeply integrating the CIM system with AMHS automatic material handling system, achieving dynamic optimization of material paths, intelligent supply-demand scheduling, reducing manual intervention, helping advanced packaging factories efficiently transition from semi-automation to full automation.

Large Model × Agent, Driving AI Manufacturing Leap

Innovatively applies 'large model × agent' technology, autonomously completing complex tasks like equipment anomaly diagnosis, production parameter optimization, quality issue traceability, promoting advanced packaging factories to upgrade from 'automation' to 'intelligence'.

4. Goals of GTRONTEC's Advanced Packaging and Testing CIM Solution

GTRONTEC's Advanced Packaging and Testing CIM Solution, centered on four core pillars—"Precision Production Control, Intelligent Equipment Maintenance, Closed-Loop Quality Management, and Fully Automated Operations"—aligns with national smart manufacturing standards. It enables a capability leap from L3 (integration level) to L5 (leadership level), ultimately achieving the "Eight Zero" operational excellence goals:

Zero Production Blind Spots: 100% digitalized production processes eliminate information gaps, enabling real-time monitoring of every process step.

Zero Quality Anomalies: Standardized production, automated EAP recipe downloads, and full-process monitoring minimize human errors.

Zero Delivery Delays: Intelligent scheduling based on equipment characteristics and real-time WIP status maximizes capacity utilization.

Zero Material Waiting Time: System-level integration enables rapid processing across workflows, reducing idle time.

Zero Rework: Closed-loop quality management through pre-analysis and in-process monitoring, coupled with an enriched knowledge base, fundamentally reduces rework.

Zero Paper Operations: Drives paperless production with systematic workflows and automated process recording.

Zero Equipment Negligence/Zero Manual Checks: Equipment connectivity and status monitoring enable preventive maintenance and automated inspections, ensuring equipment health.

Zero Customer Complaints: Full product lifecycle management proactively identifies risks and enhances customer satisfaction.

In today’s highly competitive semiconductor industry, a robust, flexible, and future-ready CIM system is essential for packaging and testing enterprises to build core competitiveness. GTRONTEC’s Advanced Packaging and Testing CIM Solution, with its full-stack product capabilities, deep industry expertise, clear evolution path, and reliable service support, helps companies tackle advanced packaging challenges. It enables the transition from "automation" to "intelligence," steadily advancing toward the vision of a "lights-out factory."