Minute-level modeling, accuracy doubled! GTRONTEC AI FDC reshapes the new benchmark for semiconductor equipment management | [CIM Acceleration, AI Direction] No.3

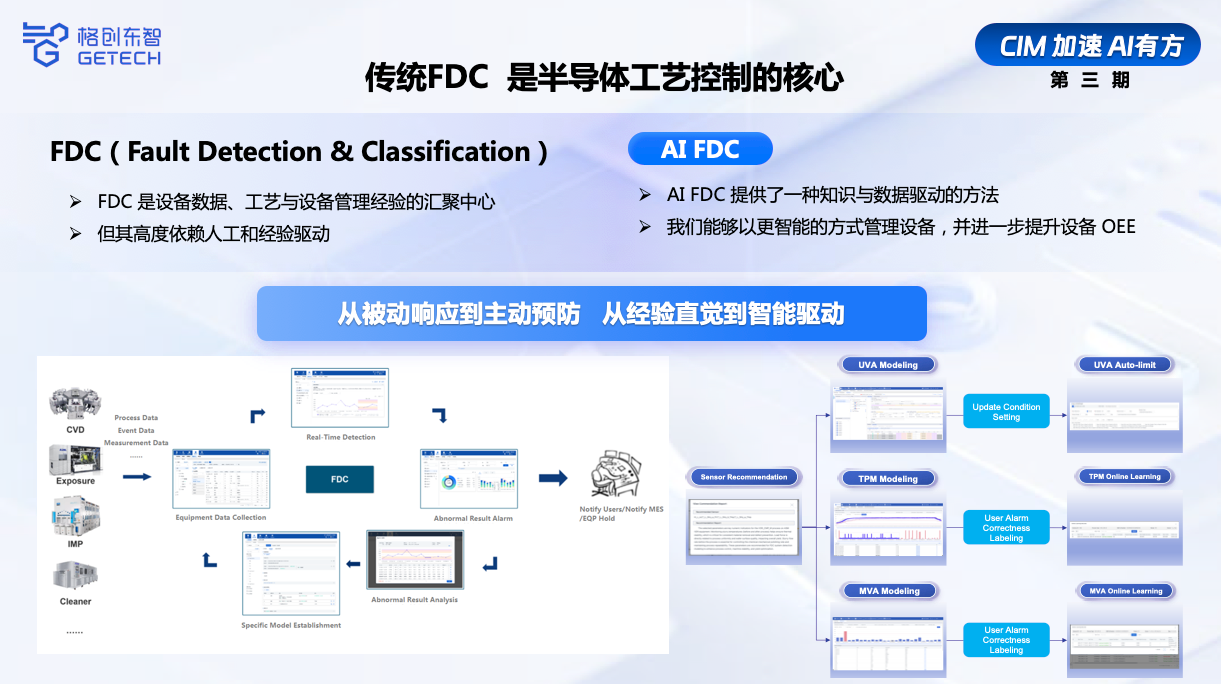

In semiconductor manufacturing, the stability and precision of process equipment directly determine wafer yield and factory operational efficiency. However, traditional FDC fault detection and classification systems highly rely on engineer experience, facing pain points such as long modeling cycles, high false positive and false negative rates, and inability to adapt to frequent recipe changes. As semiconductor factories move towards higher process precision and shorter product cycles, there is an urgent need for a smarter, more adaptive, and more precise new paradigm for process control. As a strategic industrial AI leader deeply engaged in semiconductors, GTRONTEC, based on its CIM AI Foundation ecosystem, has launched the AI FDC solution, which is a deep response to this industry challenge. By integrating industrial large models and machine learning algorithms, it promotes traditional FDC from a 'static craft' to a 'self-evolving intelligent application'.

Traditional FDC is essentially a static rule system based on manual experience. Engineers need to screen key variables from thousands of equipment parameters and set static thresholds for each variable in specific process steps. This method has three inherent shortcomings:

- Narrow vision, single-variable monitoring struggles to capture complex faults from multi-parameter coupling;

- Poor adaptability, when equipment recipes change or slight drift occurs, models require manual retuning, resulting in heavy maintenance burden;

- False alarm trap, rigid thresholds make it hard to distinguish normal fluctuations from real anomalies, causing engineers to be overwhelmed by false alarms.

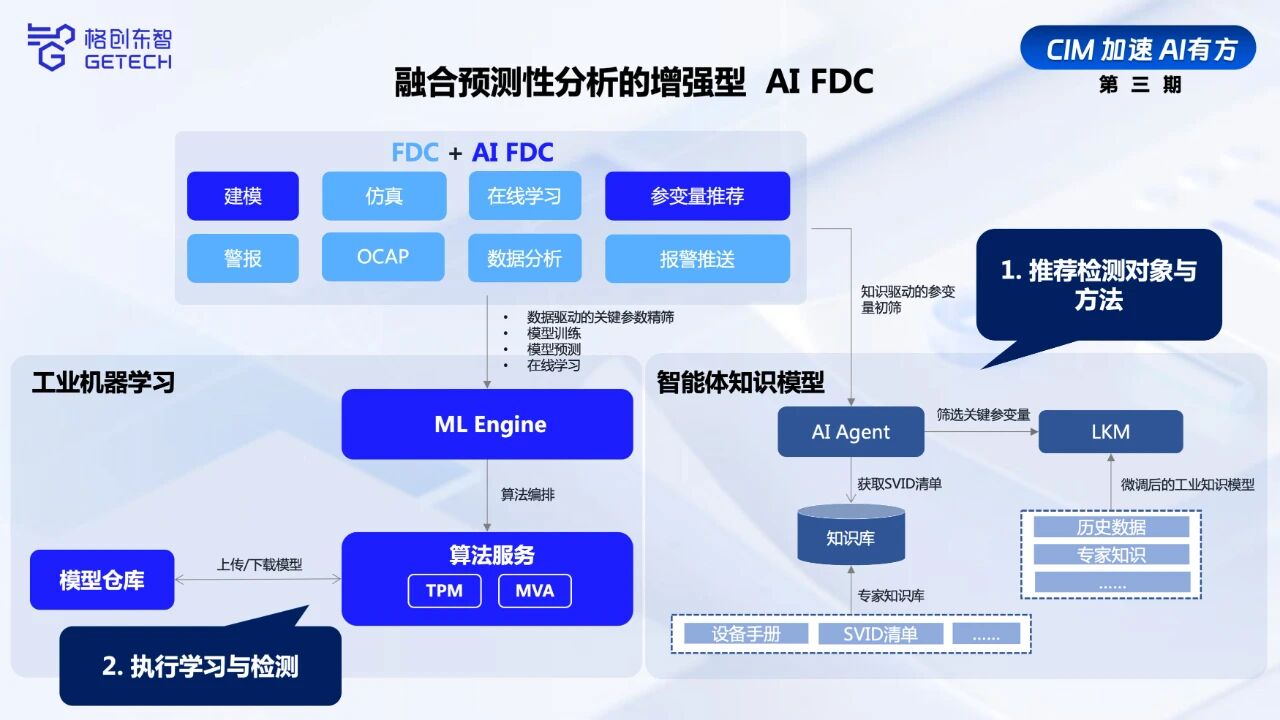

The core technological innovation of GTRONTEC AI FDC lies in building a dual-engine architecture of 'knowledge-driven + data-driven'. On the knowledge side, the system uses fine-tuned industrial large models to deeply understand unstructured knowledge such as equipment manuals, SVID lists, and expert knowledge bases, achieving intelligent initial screening and recommendation of key monitoring parameters, and generating recommendation reports with confidence and reasons, freeing engineers from tedious 'parameter selection' work. On the data side, based on the initial knowledge screening, the system uses trajectory pattern matching and multi-variable ensemble learning algorithms for data-driven fine screening modeling and continuous evolution, achieving global monitoring from single-variable to multi-variable, from point to surface.

Three Technical Engines Drive Precise and Adaptive Fault Monitoring

The value of GTRONTEC AI FDC is concretely demonstrated through its three core modeling engines.

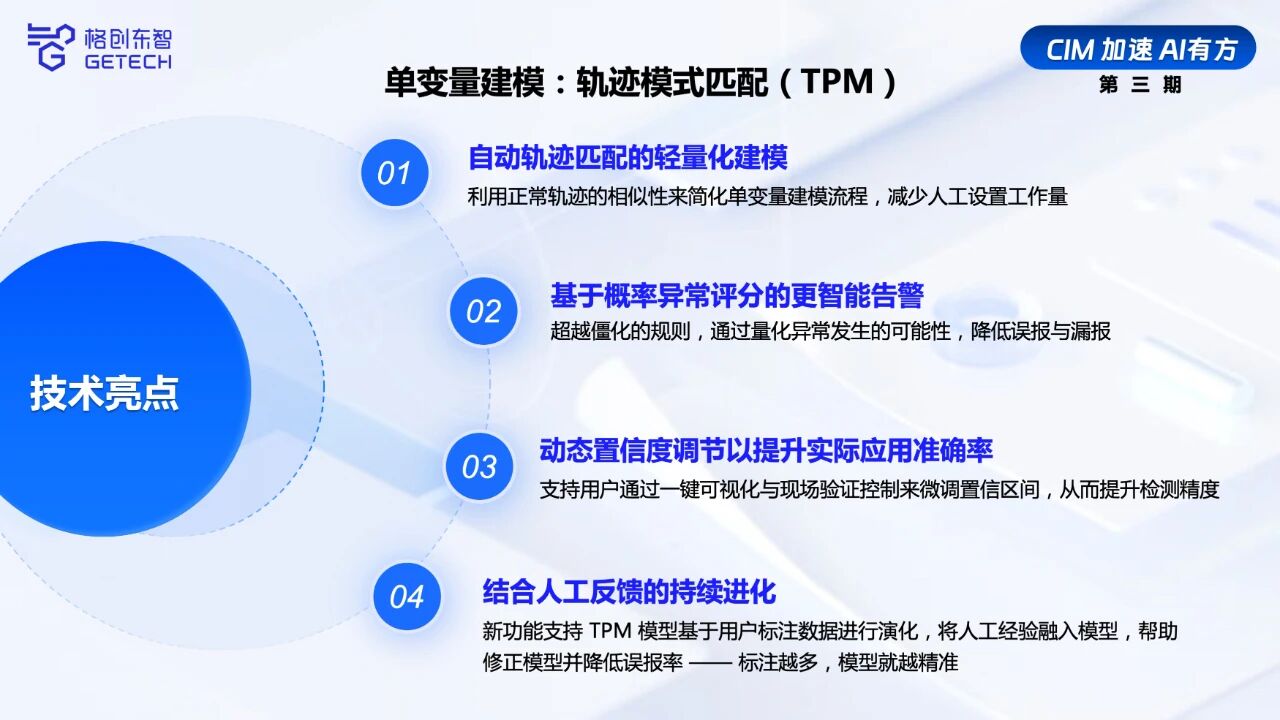

1. TPM: Pattern recognition for single-variable trajectories.

TPM no longer relies on manually set monitoring windows but automatically learns the full-process parameter trajectories of normal wafer processing, calculating 'anomaly probability' through pattern matching, significantly reducing the false positive rate of single-variable monitoring while supporting users to fine-tune confidence intervals via a visual interface and perform online self-learning based on operational feedback.

2. MVA: Integrated insight into multi-variable relationships.

It aims to solve the synergy and coupling issues between variables. Faced with complex faults, the MVA engine automatically selects the best algorithms and aggregation methods, integrating multi-dimensional parameters into a comprehensive anomaly score. Its key value lies in providing variable importance ranking, allowing engineers not only to know if an anomaly occurs but also to understand which parameters cause it, achieving model decision interpretability.

3. Adaptive Framework: Handling recipe changes.

It addresses the frequent recipe change challenges in semiconductor manufacturing. In the early stages of recipe changes, the system uses unsupervised adaptive methods to mitigate performance decay; after obtaining a small amount of test data for new recipes, it can quickly switch to semi-supervised adaptive mode, using a few labeled data to rapidly restore model performance, greatly shortening the deployment cycle for new recipe models.

AI FDC Scenario Empowerment Value Validation from CMP to CVD Processes

The value of GTRONTEC AI FDC has been validated in real scenarios.

In monitoring CMP polishing equipment for a 12-inch wafer fab, AI FDC successfully addressed challenges from multiple supplier equipment. Through intelligent recommendation and TPM, MVA multi-model collaboration, it accurately detected faults prone to false positives and false negatives in traditional methods, such as filter clogging, wafer breakage, and slurry flow instability, and with its online learning mechanism, continuously reduced false alarms during use, freeing engineers from heavy model maintenance.

In a CVD process scenario for a semiconductor client, GTRONTEC's deployed AI ADC solution, based on the MVA model, provided key variable information for fault diagnosis. By plotting the original signals and importance rankings of identified key variables, it helped engineers identify the root causes of process interference, significantly improving accuracy.

Additionally, in other scenarios facing model performance decline due to frequent recipe changes, GTRONTEC AI FDC's adaptive framework achieved rapid migration and performance recovery of models on new recipes, solving the fragmented monitoring challenges of coexisting R&D and production lines, helping clients achieve a 7.2% improvement in overall equipment efficiency (OEE) and over $5.3 million in annual operational cost reduction.

For semiconductor CIM systems, the upgrade to AI FDC marks a deep evolution from 'process automation' to 'intelligent decision-making' in the equipment control layer. As a key application in GTRONTEC's CIM AI Foundation, AI FDC collaborates with the GT Insights yield analysis platform, Octopus Agentic AI platform, and Xiaoluban AI Agent to build a full-chain intelligent network covering 'equipment-process-yield'. By integrating with the Octopus AI Agent platform and Xiaoluban AI Agent, it empowers 'equipment knowledge base Agent' to learn autonomous decision-making; through standard APIs and model services, it provides real-time, reliable process state perception and decision basis for upper systems like MES and APC; and its output of precise, interpretable anomaly data provides the most direct process clues for GT Insights' yield root cause analysis. This ecosystem not only solves the data silo issues of siloed systems but also, through the Agent framework, sediments expert experience into reusable digital assets.

From an industry perspective, the breakthrough of AI FDC lies in its 'always effective' evolution mechanism. Meanwhile, GTRONTEC AI FDC's practice validates that the future of semiconductor process control lies in building cognitive systems that can autonomously understand business, learn from data, and continuously evolve with the environment.

In the future, as semiconductor manufacturing moves towards zero-defect challenges, AI FDC will couple more deeply with CIM systems, building a bridge to 'adaptive manufacturing' for semiconductor factories, achieving the high-quality development goals of extreme yield, extreme efficiency, and extreme cost pursued by semiconductor manufacturing, and providing a feasible path from 'catching up to leading' for the industry.

For more details, contact: 400-600-2869.