Repeat Order Continues! GTRONTEC NTB Equipment Receives Additional Orders from Top Memory Manufacturer, Empowering 'Last Meter' Smart Logistics

Recently, GTRONTEC's Kunshan AMHS Manufacturing Base once again completed an important shipment—delivering NTB near-tool buffer equipment (hereinafter referred to as "NTB equipment") to a leading domestic semiconductor memory manufacturer's 12-inch wafer fab. It is worth noting that this is a new round of repeat purchases by the customer after previously procuring multiple Normal Stockers, signifying that GTRONTEC continues to gain customer recognition in the field of semiconductor automated material storage solutions, and its product repurchase and scenario extension capabilities are continuously strengthening.

In 2024, GTRONTEC established its AMHS business subsidiary—Wilson Optimus —through a strategic acquisition. Based on Wilson Optimus 's self-developed and self-produced OHT, Stocker, MCS, and other hardware and software products, GTRONTEC comprehensively covers semiconductor logistics automation needs, becoming the only domestic company that can simultaneously provide integrated AI+CIM+AMHS semiconductor smart factory solutions combining hardware and software.

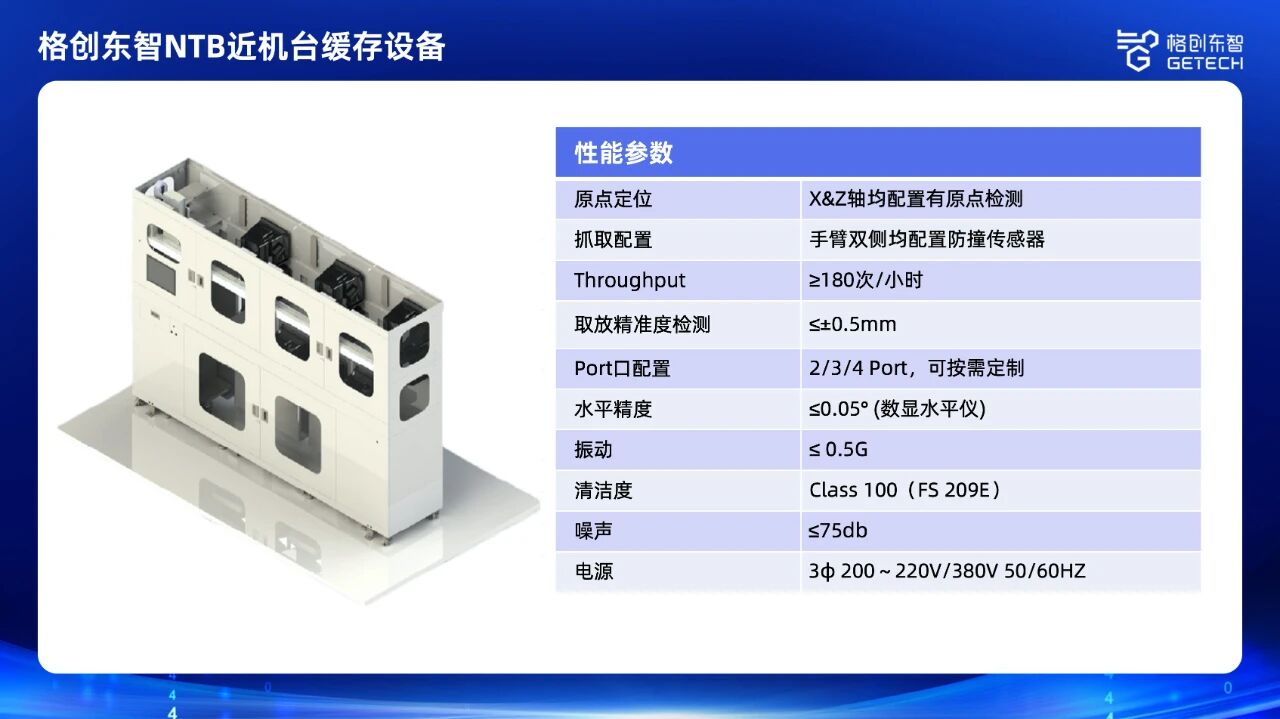

NTB equipment is an important member of GTRONTEC's Stocker product family. As a key hub in the AMHS system connecting OHT and process equipment, it is mainly used to achieve efficient material transfer in the "last meter." When OHT feeding is untimely or equipment is waiting for materials, NTB equipment can serve as a temporary buffer and handover station, effectively reducing equipment waiting time, improving equipment utilization rates, and resolving production line logistics bottlenecks.

GTRONTEC's NTB equipment features "close proximity" and "high frequency." It adopts a modular splicing design and can be embedded next to the equipment; the fastest single Load/Unload time is ≤10 seconds, and it can complete at least 3 consecutive Load/Unload tasks within 1 minute, perfectly adapting to high-frequency material change needs.

The delivered NTB equipment has E84 one-click rapid switching capability. E84 is the core standard protocol for communication between semiconductor equipment. Traditional switching methods usually rely on manual reconfiguration, which is time-consuming and error-prone. Through hardware and software collaborative innovation, GTRONTEC's NTB equipment achieves mode switching with one click via the local touch screen or remote MCS system without power interruption or wiring changes, and the entire process can be completed within 10 minutes, greatly enhancing production line flexibility and responsiveness.

With rich equipment docking experience, GTRONTEC's NTB equipment has become the preferred solution for "the last meter near the tool" in advanced process production lines. As of now, GTRONTEC's NTB equipment has cumulatively shipped over 20 units, with 95% applied in domestic mainstream 12-inch advanced process wafer fabs, and the core customer repurchase rate exceeds 80%.

In the future, GTRONTEC will continue to practice the concepts of "technology independence, scenario adaptation, and service agility," improve the "AI+CIM+AMHS" integrated solution, and inject sustained momentum into the high-quality development of China's semiconductor industry.