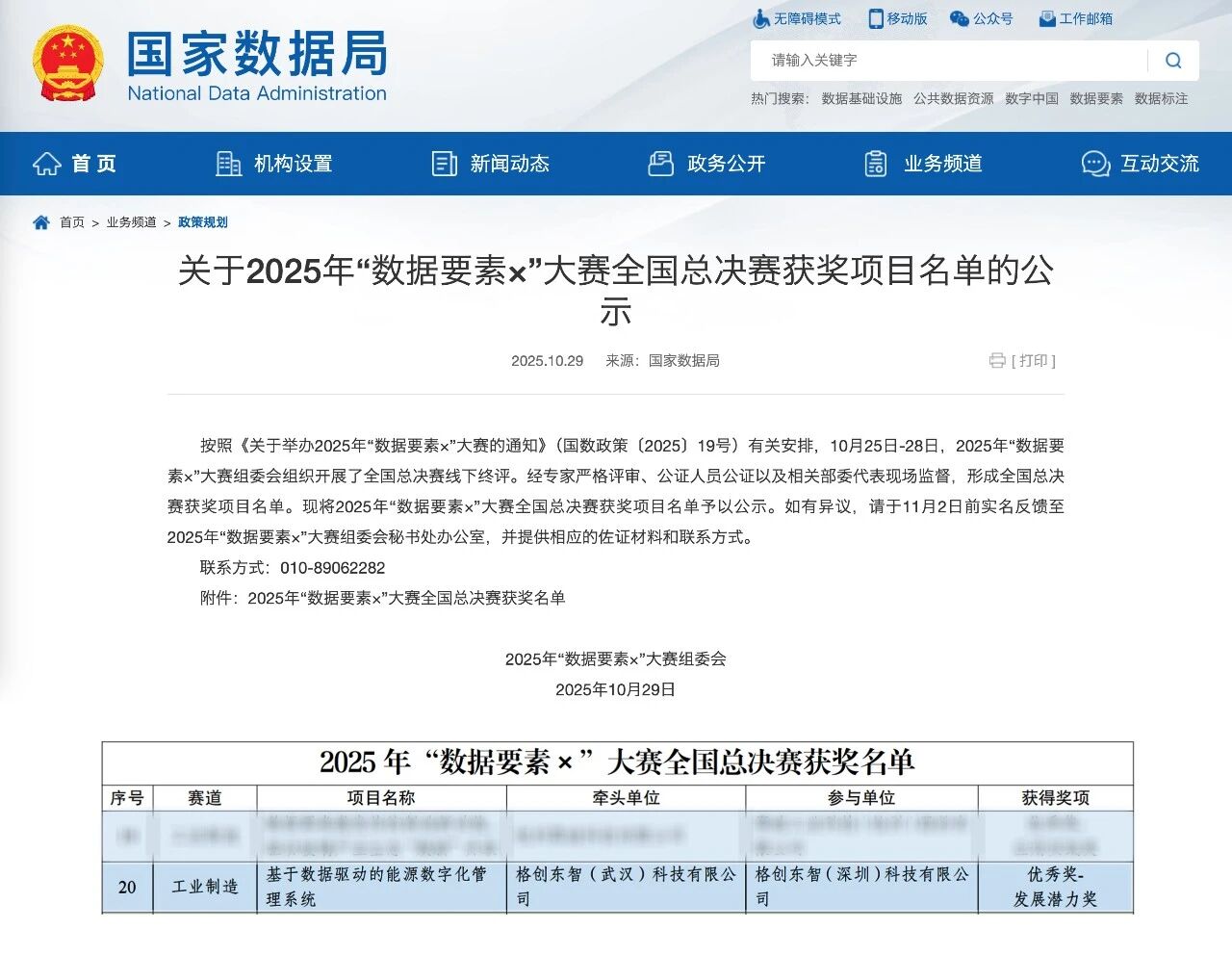

Winning the Development Potential Award at the 2025 'Data Elements ×' National Finals, GTRONTEC Drives Industrial Energy and Carbon Management Innovation with Data

On November 2, 2025, the publicity period for the winners of the 'Data Elements ×' National Finals ended. GTRONTEC stood out in the industrial manufacturing track with its 'Data-Driven Energy Digital Management System' project (referred to as the Energy Carbon Brain Platform), and won the 'Development Potential Award'.

The 'Data Elements ×' competition is China's first national-level event focusing on the development and application of data elements, jointly organized by the National Data Bureau, the Cyberspace Administration of China, the Ministry of Industry and Information Technology, and over 20 other ministries and agencies. With the theme 'Data Empowerment Multiplies Upward', the competition covers innovative applications in 14 key areas including industrial manufacturing, modern agriculture, and commercial circulation, aiming to unlock the value of data elements and promote high-quality economic and social development. This edition attracted over 22,000 teams nationwide, with 893 projects advancing to the national finals, making the competition highly intense.

GTRONTEC's 'Energy Carbon Brain Platform' is a platform-level product for energy and carbon management in industries such as integrated circuits, new displays, and new energy batteries. The system builds a full-process data governance closed loop of 'collection, storage, management, and application' by integrating multi-dimensional data from industrial sites, including electricity, water, gas consumption, temperature, humidity, pressure, flow, output, capacity, and equipment operation status, helping enterprises achieve value conversion of energy and carbon data, cost reduction, and efficiency improvement.

Technology Breakthrough, Building the Foundation of Energy and Carbon Digital Intelligence Management

GTRONTEC's 'Energy Carbon Brain Platform' integrates key technologies into the value chain of 'collection, storage, management, and application', creating a value journey for the full-link flow of energy and carbon data elements.

In the data collection phase, the platform relies on a self-developed industrial IoT platform to achieve wide-area device connectivity and millisecond-level massive data collection, significantly improving concurrent performance in data collection and transmission through heterogeneous ubiquitous networks and system load balancing.

In data storage, the platform adopts a lakehouse architecture, combining row-column hybrid storage, intelligent compression, and hot-cold tiering technologies to achieve efficient storage and query of TB-level energy and carbon data, reducing storage costs by 50% and improving query performance by 3 times.

In data management, the system integrates data lineage tracing, quality rule engines, metadata management, distributed computing, and stream-batch integration technologies to achieve massive data processing and real-time insights.

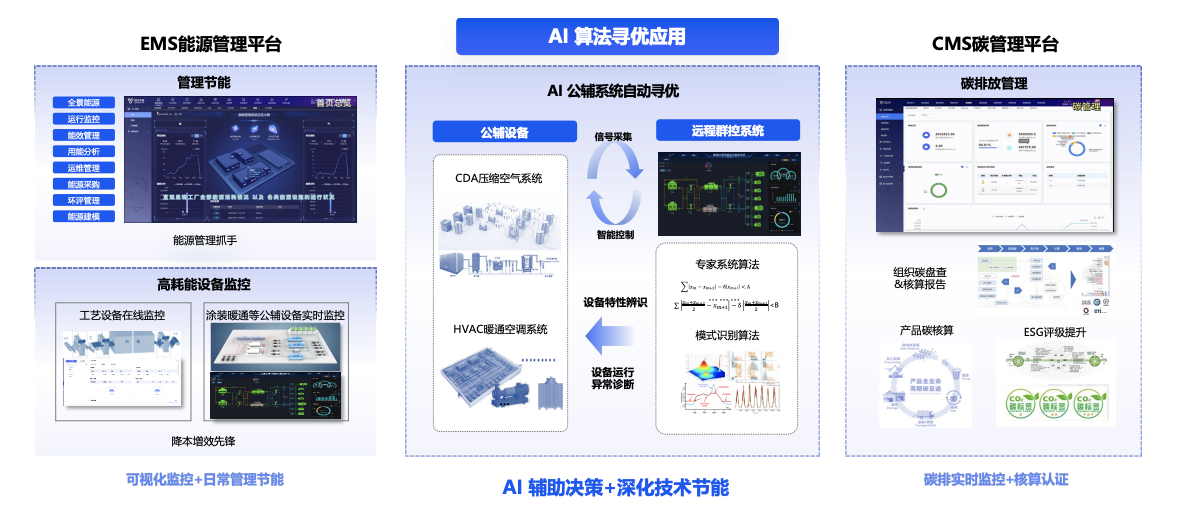

In data application, based on high-quality energy and carbon data, the system innovatively builds a dual-layer AI architecture of 'energy-carbon large model + scenario-specific small models' to achieve core functions such as energy consumption prediction, carbon emission tracing, and intelligent scheduling, with prediction accuracy exceeding 95% and scheduling strategy response time less than 1 second. Addressing the core issue of data circulation and sharing difficulties in the industrial field, the system promotes data exchange and sharing by transferring model parameters instead of raw data while protecting data privacy.

Practice Leadership, Promoting the Implementation of Dual Carbon Goals in Manufacturing Sites

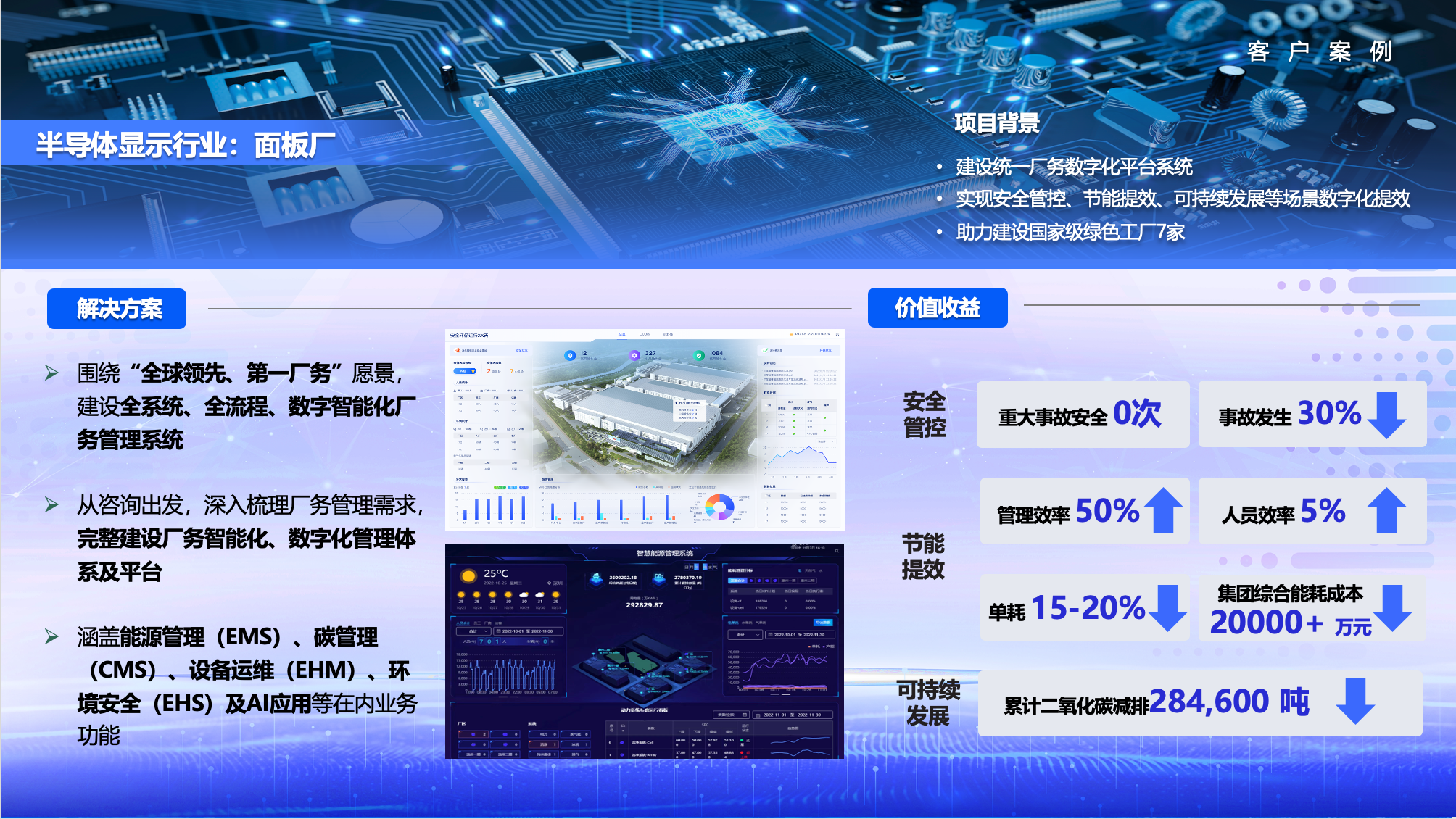

In serving a leading semiconductor display company, GTRONTEC built a comprehensive, full-process, digital intelligent plant management system, helping it establish 7 national-level green factories. This assisted the client in reducing annual comprehensive energy consumption costs by approximately 200 million yuan, improving management efficiency by 50%, and achieving a win-win in economic and environmental benefits.

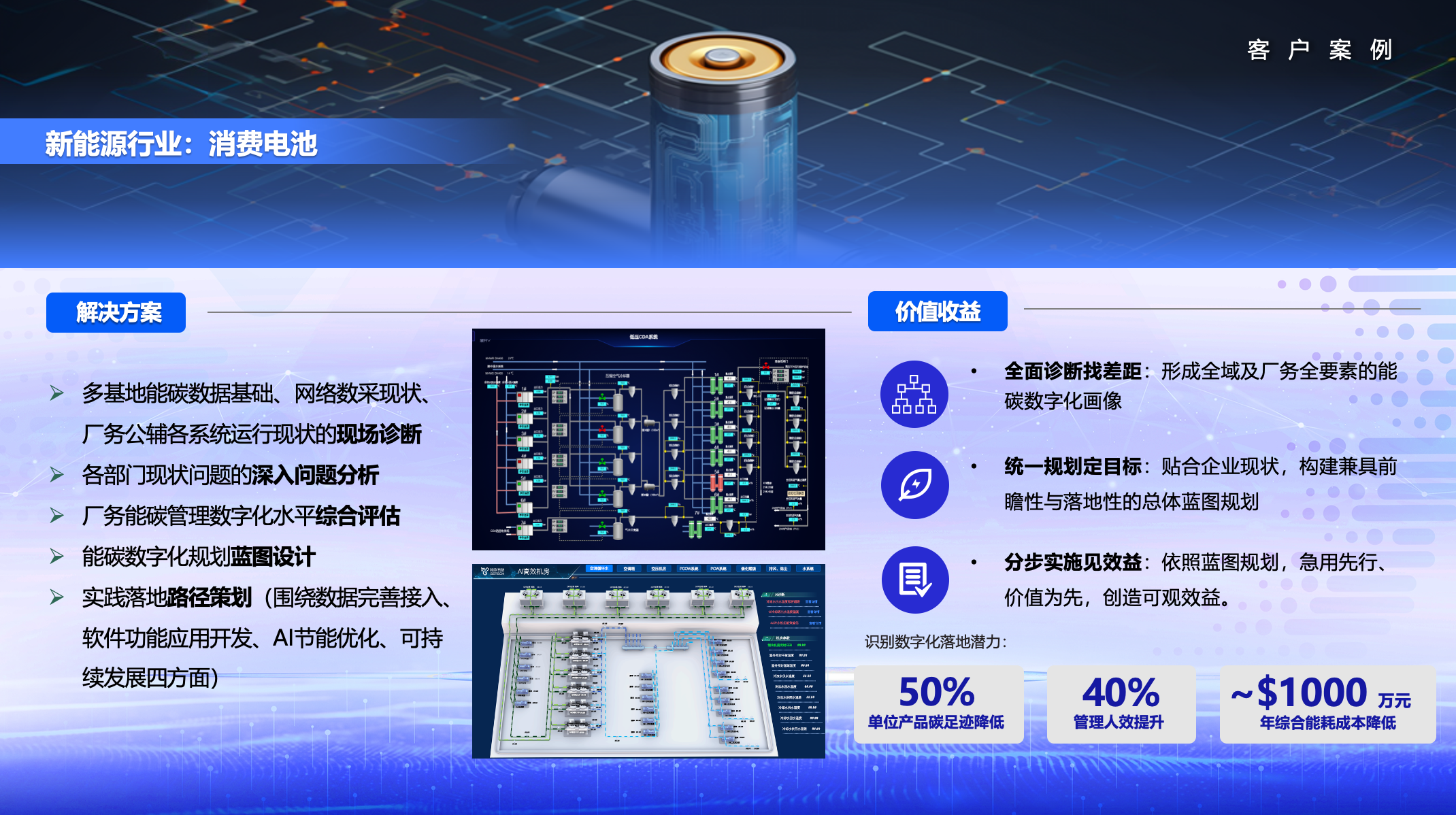

In serving a globally leading consumer battery manufacturer, GTRONTEC achieved rapid access and efficient integration of tens of thousands of energy and carbon points across multiple sites through a multi-protocol adaptation engine and lakehouse architecture, building a solid and unified energy and carbon data foundation for the enterprise. This helped the client reduce annual comprehensive energy consumption costs by approximately 10 million yuan, improve management efficiency by 40%, and lower the carbon footprint per unit product by 50%, enabling data intelligence throughout the entire energy and carbon management process.

In serving a globally renowned 3C electronics manufacturer, GTRONTEC focused on building a 'Unified Smart Plant Energy Carbon Management Platform', integrating AI algorithms, digital twins, and other cutting-edge technologies to achieve fine-grained management of energy use and carbon emissions throughout the entire process, with particular emphasis on intelligent optimization of key energy-consuming systems such as HVAC. Nearly 400 smart meters, water meters, flow meters, and other measurement devices were added, completing energy data access for over 40,000 points. AI energy-saving optimization algorithms were deployed in 4 HVAC rooms, achieving intelligent control of nearly 400 end air conditioners with wind-water linkage, resulting in a 20% energy saving rate, aiming to set a new benchmark for industry energy and carbon management.

Fulfilling Responsibilities, Writing a New Chapter in Industrial Green Transformation

Over the past three years, the platform has been successfully applied in over 100 factories in sectors such as semiconductors, new energy, and 3C manufacturing, cumulatively reducing energy consumption expenditures by over 200 million yuan, lowering annual comprehensive energy consumption by 15% to 20%, improving management efficiency by 50%, and reducing carbon emissions by over 350,000 tons, demonstrating significant economic and social benefits. Additionally, the project has spawned new professions such as new energy operation and maintenance and carbon asset management, creating over 8,000 jobs annually.

This award not only showcases GTRONTEC's technological innovation and smart manufacturing synergy but also reflects the company's strength in driving industrial green transformation with data elements. In the future, GTRONTEC will continue to deepen the exploration and application of data value in the industrial intelligence field, using data to drive the manufacturing industry towards green, efficient, and sustainable development, contributing to China's 'Dual Carbon' goals and the digital transformation of manufacturing.