Digital Intelligence Towards the Core, Gathering Momentum for Win-Win! GTRONTEC Showcases AI+CIM+AMHS Panoramic Solution at 2025 Qiushi Yuan Semiconductor Industry Summit

From November 15 to 16, the 2025 Qiushi Yuan Semiconductor Industry Summit and the 10th Anniversary Celebration of the Qiushi Yuan Semiconductor Alliance were held grandly at the Caohejing Conference Center in Shanghai. GTRONTEC, a leading enterprise in smart manufacturing industrial software and industrial AI solutions strategically focusing on the semiconductor field, was invited to participate. It systematically showcased its mature AI+CIM+AMHS semiconductor smart factory integrated software-hardware solution, providing the industry with a credible path for smart manufacturing upgrade through detailed implementation data and benchmark cases.

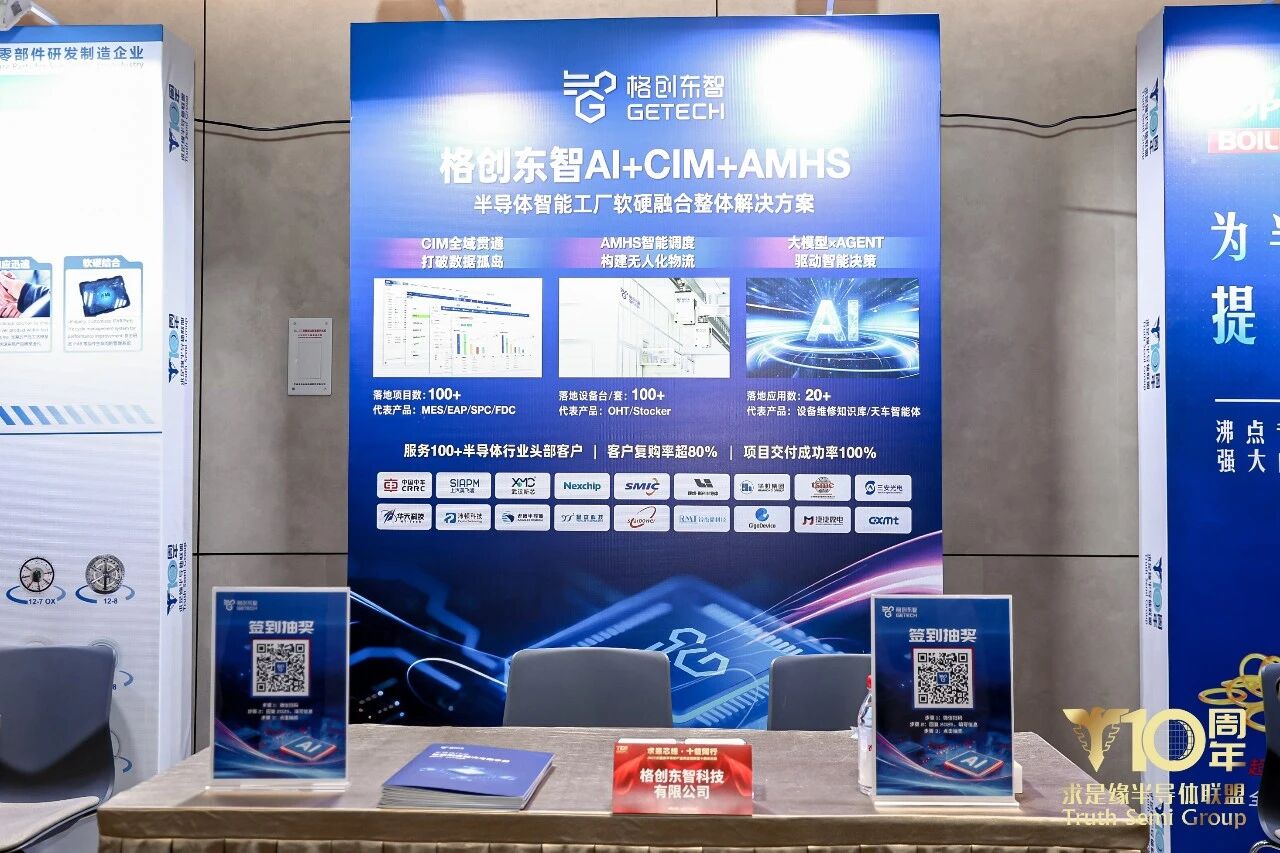

In the semiconductor industry, the CIM system is known as the factory's "chief commander," responsible for coordinating complex manufacturing processes. At the summit booth, GTRONTEC first showcased using CIM to build the "brain" of the semiconductor factory. Through core systems like MES, EAP, and SPC, it achieves full data integration from production execution and equipment management to quality control, effectively breaking information silos and laying a solid foundation for smart manufacturing. On this basis, it uses the AMHS automated material handling system to build the "blood" of the semiconductor factory, directing hardware devices like OHT overhead transport vehicles and Stocker wafer storage systems to perform real-time unmanned logistics transport, forming an efficient and precise unmanned logistics system. Meanwhile, GTRONTEC deeply embeds AI and large model technologies into production scenarios to form intelligent agents, driving intelligent decision-making and actions for the "brain" and "blood." For example, on mass production lines, AI FDC can detect minor abnormalities in equipment parameters in real-time, achieving early warnings; the "equipment knowledge base assistant" intelligent agent can quickly identify unstructured data like "handbooks," forming an equipment knowledge base and providing precise maintenance guidance through natural language dialogue, significantly reducing downtime. Additionally, the "crane intelligent agent" autonomously calculates optimal paths, dynamically responds to production rhythm changes, and achieves scheduling optimization. This "integrated software-hardware, data-driven" architecture is key to addressing the increasing complexity of semiconductor manufacturing and improving production line efficiency and yield.

The value of this solution has been fully validated in extensive implementation applications. In the CIM field, its core products like MES, EAP, SPC, and FDC have become the "digital hub" for over 100 benchmark factories. In AMHS, its intelligent hardware such as OHT and Stocker has delivered over 100 series of equipment, ensuring precise and efficient material flow. In the most forward-looking AI application layer, over 20 agent applications like the "crane intelligent agent" are effectively operating on production lines, marking the shift of intelligent decision-making from concept to large-scale practice. These services have forged GTRONTEC's high customer repurchase rate of 80% and 100% project delivery success rate, establishing the company's core competitiveness.

GTRONTEC's unique advantage lies in its "integrated software-hardware" DNA and closed-loop service capabilities accumulated from deep cultivation in the semiconductor industry. The ability to win long-term trust from many top clients and achieve high repurchase rates stems from its deep understanding of semiconductor manufacturing processes and the engineering capability to seamlessly integrate AI technology into complex scenarios. Whether it's MES's precise control of complex processes, EAP's stable connectivity with thousands of equipment types, or the demanding requirement for millisecond-level response in scheduling systems for thousands of cranes, GTRONTEC can provide end-to-end overall delivery based on methodologies validated through top client service practices, making it the most reliable partner for clients on their intelligent transformation journey.

This Qiushi Yuan Semiconductor Industry Summit gathered many experts and enterprises from the industrial chain's upstream and downstream. GTRONTEC's appearance became one of the focal points, with its solid results providing clear answers to real challenges in semiconductor manufacturing. In the future, as the semiconductor industry moves towards more advanced processes and higher flexible manufacturing demands, GTRONTEC will continue to deepen the integration and innovation of AI and industrial know-how, empowering the high-quality development of China's semiconductor industry.