Attended the Xinbaihui 2025 Annual Symposium, GTRONTEC Unlocks the Roadmap for Industrial AI from Technological Exploration to Intelligent Manufacturing Deepening

On November 15, the Xinbaihui 2025 Annual Symposium was successfully held in Shanghai. The theme focused on 'AI+ Navigation Map: From the Blue Ocean of Technology to the Deep Sea of Industry'. It gathered the wisdom of over 30 Xinbaihui members and more than 100 leaders from industry, academia, and research to discuss the path of AI technology towards industrial deepening. He Jun, Vice President of TCL Industrial and CEO of GTRONTEC, was invited to attend as a member of Xinbaihui and delivered a keynote speech. Drawing from years of experience in deepening industrial digital transformation, he provided a realistic paradigm for AI upgrading in China's advanced manufacturing industry.

He Jun pointed out that the AI transformation in manufacturing has entered the 'deep water zone', and its core anchor is no longer the technology itself, but 'business value'. He believes that leading manufacturing enterprises must build core competitiveness through continuous technological self-research and scenario deepening. Taking TCL as an example, it invests over 100 billion yuan annually in R&D, with cumulative patent applications exceeding 110,000 (including 18,000 PCT patents), and the direct economic benefits brought by AI technology in 2024 exceeded 5.4 billion yuan. This 'investment-benefit-reinvestment' model is forming a virtuous cycle that promotes continuous technological iteration and deepening.

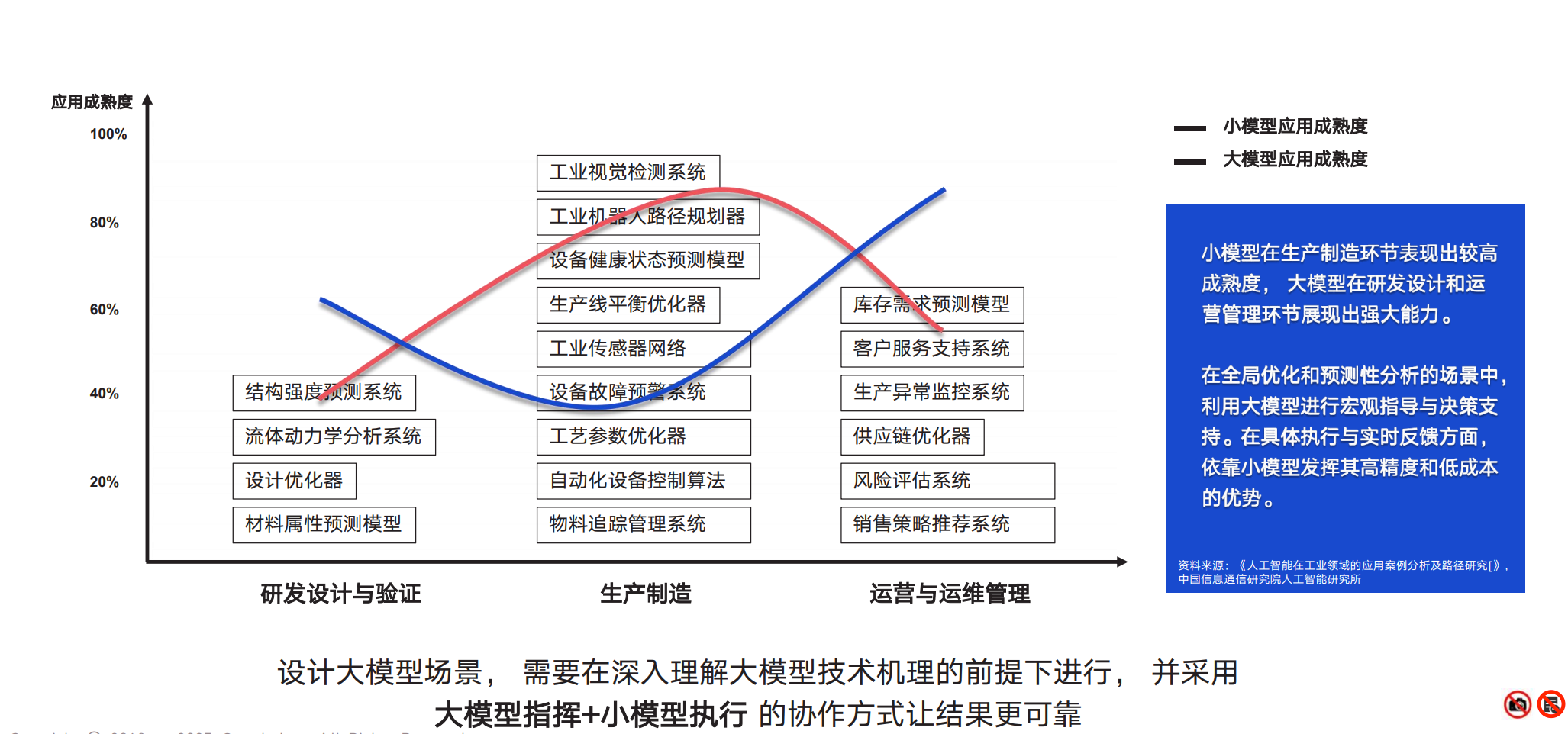

In the choice of technical route, He Jun shared GTRONTEC's highly forward-looking 'large and small model collaboration' strategy. He pointed out that in manufacturing, large models and small models are not substitutes but collaborative and symbiotic. Large models, with their powerful cognitive and reasoning capabilities, focus on macro scenarios such as R&D design, knowledge Q&A, and supply chain optimization that require global decision-making and industry knowledge integration; while small models, with their advantages of high precision, low latency, and low cost, specialize in micro execution scenarios that require real-time response, such as industrial visual inspection, equipment predictive maintenance, and process parameter optimization. Only by combining the two can the breadth and precision of intelligence be balanced.

This route has been truly applied in production lines. Taking TCL Huaxing's 'Intelligent Equipment Operation and Inspection Assistant System' as an example, the system uses large models to build an equipment fault handling assistant, helping engineers quickly query knowledge and locate faults, and combines small models for real-time monitoring and warning. After the project goes live, it is expected to reduce fault time by 241.4 hours per month, with an annualized benefit of up to 30 million yuan. Another typical case is the 'Yield Analysis Agent' for frontline quality engineers, which can autonomously identify anomalies and generate complete analysis reports, freeing engineers from tedious data analysis to focus on higher-value decisions.

At the implementation level, He Jun emphasized the importance of organization and platforms. TCL's self-created 'Iron Triangle Organization Model', coordinating the three main forces of the Digital Transformation Center, TCL Industrial Research Institute, and GTRONTEC, penetrates AI technology into multiple scenarios including equipment operation and maintenance, production scheduling, quality analysis, R&D design, and even supply chain operations, ensuring the overall planning and engineering implementation of the AI strategy. At the same time, GTRONTEC's layout at the AI platform level has matured. Products such as the Octopus Brain AI Agent Platform, Xingzhi Large Model, and Smart Factory Hub are driving GTRONTEC to establish a digital-intelligent foundation for 'full-scenario, full-process intelligence'.

He Jun believes that the direction of manufacturing AI must deepen 'self-research' and 'open cooperation'. GTRONTEC is establishing an Industrial AI Joint Laboratory with the University of Hong Kong, focusing on 'innovation and practical application of industrial AI technology', aiming to tackle core challenges such as 'multi-constraint reasoning models', helping GTRONTEC extend its technological reach to the basic research level, and through industry-academia-research linkage, promote AI from internal enterprise empowerment to the prosperity of the entire industry ecosystem.

This speech not only clearly outlined the roadmap for manufacturing AI from technological exploration to intelligent manufacturing deepening, but also highlighted the unique value of GTRONTEC as a leader in industrial AI: it possesses both the deep manufacturing genes and full-scenario implementation experience derived from TCL, and the platform-based, systematic ability to transform AI technology into actual productivity. In the semiconductor field, a core manufacturing area related to national competitiveness, GTRONTEC is driving the industry towards a high-quality future at full speed with its integrated hardware-software solutions.