GTRONTEC 12-inch GMES System: Strengthening the Foundation of Intelligent Manufacturing, Leading the New Digital Journey for 12-inch Wafer Fabs (Part 1)

In the critical period of the semiconductor industry moving towards advanced processes, the Manufacturing Execution System (MES) has become the core engine for improving production efficiency, ensuring product quality, and achieving digital transformation. Especially for 12-inch wafer manufacturing, where process complexity soars, yield control is stringent, and full-process automation is urgently needed, MES systems face higher challenges.

Trends in 12-inch Wafer Fabs and Bottlenecks of Traditional Systems

Against the backdrop of intense global semiconductor capacity and technology competition, 12-inch wafer fabs are under unprecedented 'multiple overlapping pressures': they must rapidly advance mass production expansion lines, while frequently conducting new process verification and engineering experiments; they must accelerate the pace of new product introduction, while achieving fine balance between yield, cost, delivery time, and compliance regulations. Any delay in response may amplify into capacity loss and customer trust risk.

Most traditional MES/CIM systems were born in a 'relatively stable' manufacturing era, and for current 12-inch wafer fabs, they have exposed three major shortcomings:

Slow process modeling and heavy changes, lacking sufficient 'flexibility' for high-frequency new product introduction (NPI) and experimental wafers;

Fragmented equipment, quality, and logistics data, with insufficient visualization and collaborative decision-making capabilities;

Limited automation and intelligence levels, making it difficult to support fully automated production and intelligent scheduling.

GTRONTEC 12-inch GMES System: Tailor-made for New-era 12-inch Wafer Fabs

As an industrial intelligent solution provider deeply rooted in the semiconductor industry, GTRONTEC deeply integrates CIM system architecture with smart manufacturing concepts, launching the new-generation 12-inch GMES system.

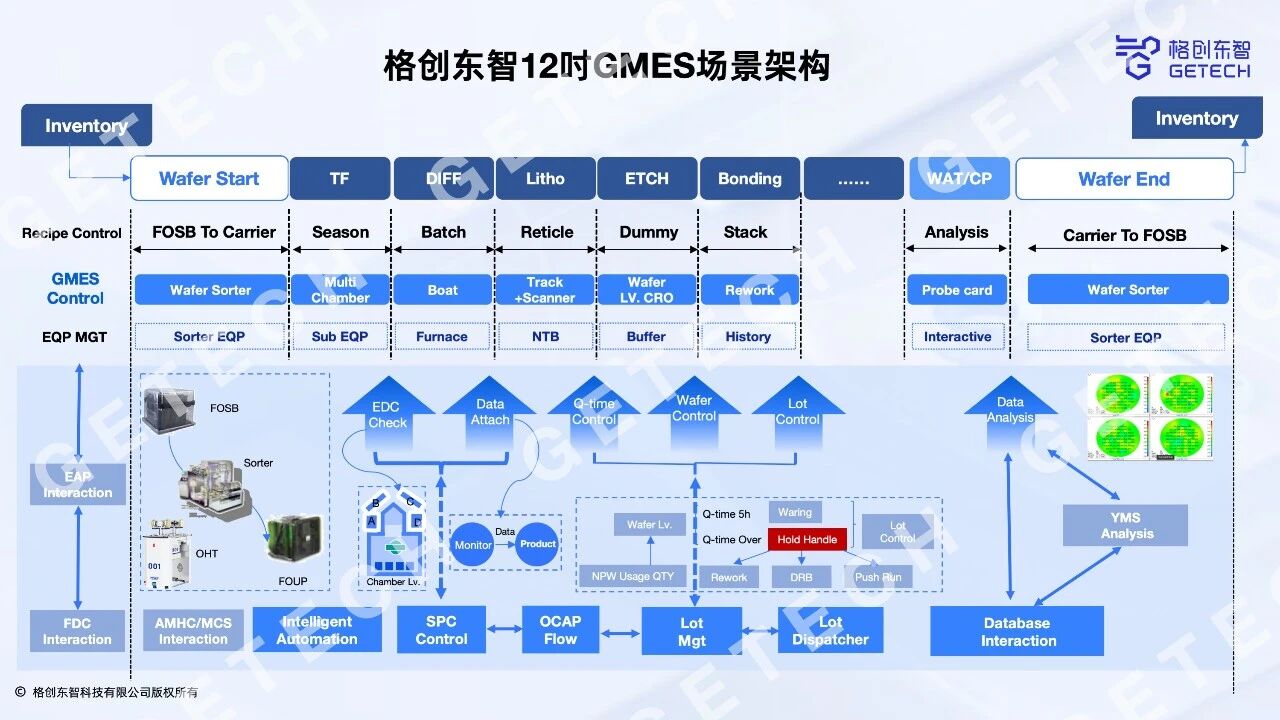

The system is based on a 99.999% high-availability architecture, achieving full-process function coverage and seamless system integration, comprehensively supporting fully automated operation of wafer fabs, accurately addressing various complex scenarios in large-size wafer manufacturing, providing a full lifecycle digital solution for global 12-inch wafer fabs from trial production to mass production, accelerating towards 'lights-out factory' and new heights of smart manufacturing.

Business-Driven Layout: Functions Covering the Entire Key Manufacturing Process

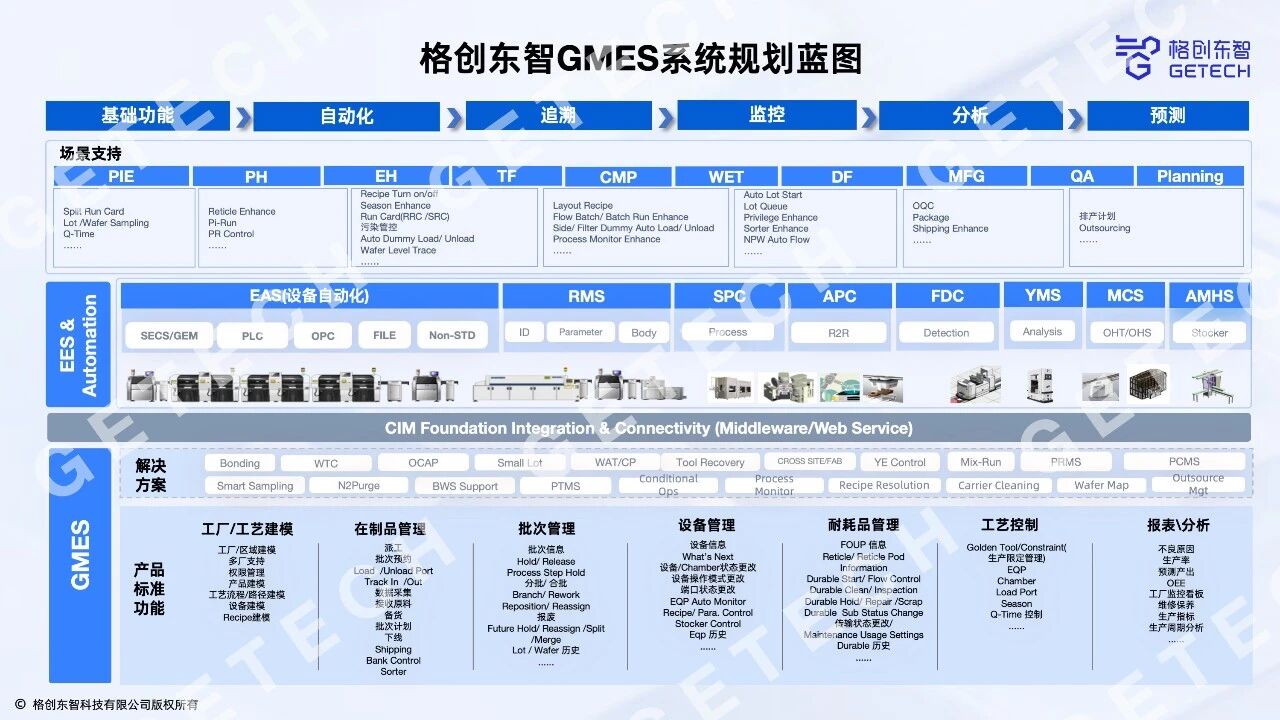

GTRONTEC GMES system, targeting the business characteristics of 12-inch wafer fabs, builds a complete functional system around 'planning-manufacturing-equipment-quality-traceability', covering key scenarios throughout the entire process, while providing specialized solutions for core processes.

Core Business Functions

Planning and Scheduling: Combining orders and Fab capacity constraints, providing factory-level/module-level production plans and batch rhythm control, offering decision guidance for dispatching.

WIP and Batch Management: Supporting multiple types of batches such as production batches and engineering batches, covering complex operations like Split/Merge, Hold/Release, Rework, ensuring traceability and control of batches in high-engineering-volume and high-change environments.

Equipment and Automation Integration: Deeply linking with systems like EAP/EAS, AMHS, MCS, RTD, achieving fully automated scenarios such as Auto Wafer Start and automatic loading/unloading, truly making equipment 'ask for materials without human intervention'.

Quality and Process Control: Through modules like EDC, SPC, FDC, achieving full-process quality management from measurement data collection, rule judgment, to exception closure.

Tracking and Traceability: Based on multi-dimensional information like work orders, Lots, Wafers, achieving full-chain traceability from raw materials to shipment, meeting compliance and audit requirements.

Key Process Specialized Solutions

Thin Film: Optimizing multi-chamber dispatching and recipe control, ensuring process consistency.

Chemical Mechanical Polishing (CMP): Specialized Recipe control module, effectively reducing equipment idle time and improving utilization.

Chemical Vapor Deposition (CVD): Integrated with ECS system, supporting control rules for equipment/chamber/carrier ports, achieving automatic parameter issuance and collection.

Furnace: Adopting Pre-Batch and Flow Batch management mechanisms, preventing Q-Time overtime, intelligently monitoring wafer usage through Layout Recipe.

Lithography (Litho): Integrated with reticle management and photoresist management, achieving precise control of core consumables.

Etching (ETCH): Supporting Pi-Run intelligent triggering and automatic management of Inside Dummy Wafers, enhancing intelligent processing levels.

In the current context where advanced processes, power devices, compound semiconductors, and multiple tracks are advancing simultaneously, the competitiveness of 12-inch wafer fabs is no longer just a matter of 'investing in more equipment,' but how to use a scalable and evolvable digital foundation to support continuous process innovation and business growth.

For more on the architectural advantages, refined management solutions, and intelligent applications of GTRONTEC's 12-inch GMES system, please stay tuned for the next issue: 'GTRONTEC 12-inch GMES System: Strengthening the Foundation of Intelligent Manufacturing, Leading the New Digital Journey for 12-inch Wafer Fabs (Part 2).'