As a national-level 'Specialized, Refined, Unique, and New' little giant enterprise, Gaoxin Technology is the first domestic semiconductor integrated circuit production enterprise that can simultaneously provide both uncooled and cooled infrared detectors. By partnering with GTRONTEC Dongzhi to implement the CIM project, it will accelerate digital transformation and build an advanced semiconductor production management benchmark factory.

As a pioneer in infrared core components, Gaoxin Technology not only has front-end and back-end production lines for silicon wafers but also possesses a complete process for cooled products, from raw material purification and growth to chip tape-out, manufacturing, packaging, and testing. Its products feature high thermal sensitivity, good reliability, and performance metrics that reach international leading levels.

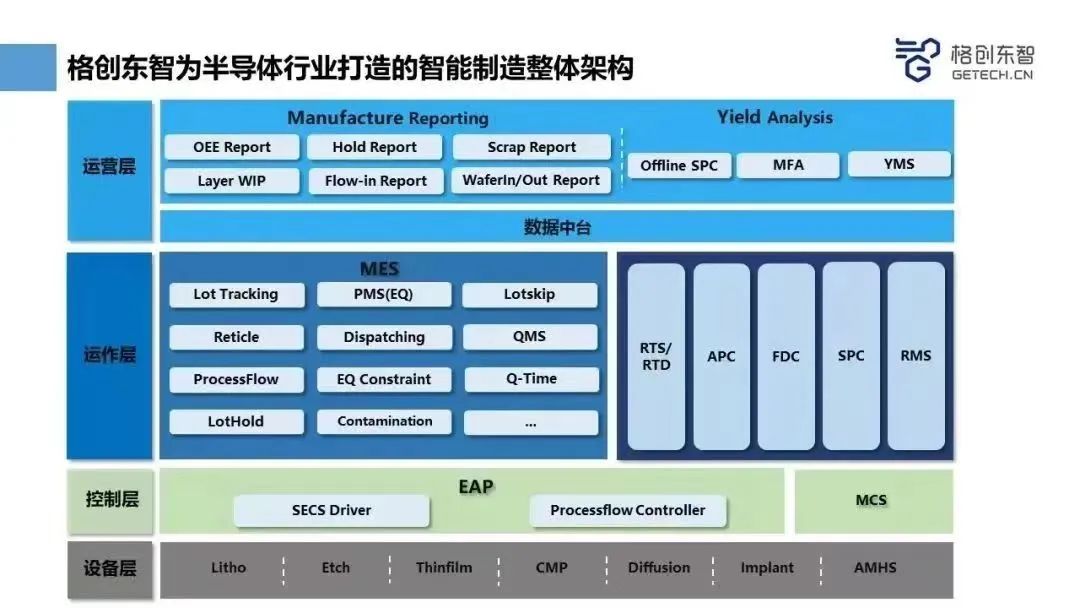

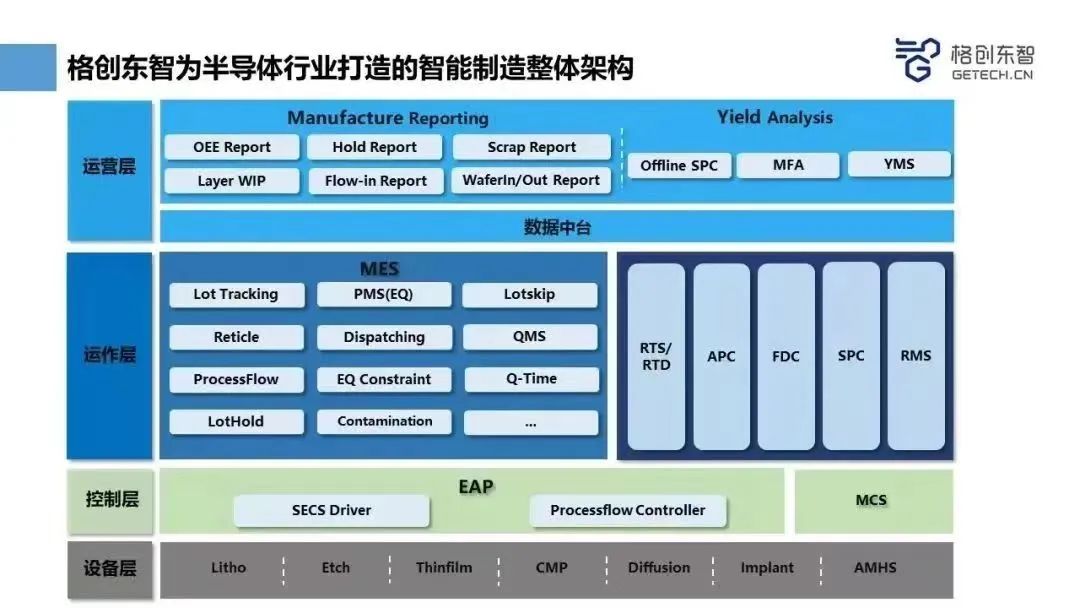

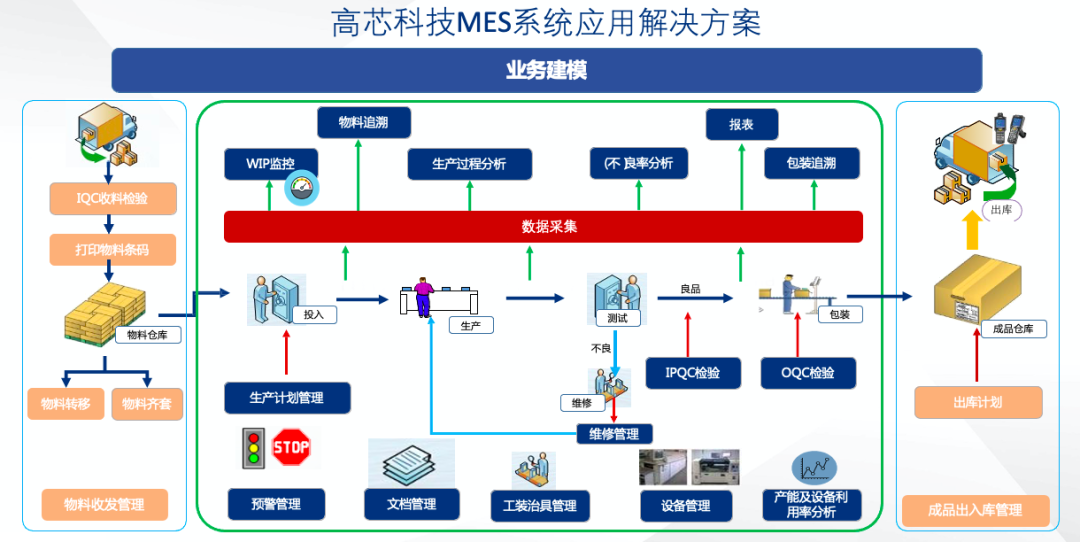

Therefore, the overall CIM solution provided by GTRONTEC Dongzhi covers not only the uncooled MEMS chip manufacturing, wafer-level packaging, module packaging, metal packaging, ceramic packaging, and testing of silicon wafers but also includes all production lines and workshops for crystal growth, substrate epitaxy, chip devices, cooled packaging, coolers, and cooled coupling testing, fully meeting Gaoxin Technology's diverse business needs.

”

“Through the CIM project construction, we will support Gaoxin Technology in achieving full-process control for both cooled and uncooled product production, enabling real-time, accurate, and effective collection and processing of production data. By integrating with systems like ERP, WMS, PDM, OA, etc., the CIM system will play a pivotal role in data sharing, preparing the platform and data for future intelligent equipment control, big data analysis, and deep AI applications.”

Xiao Changbao, Chief Architect and Head of Semiconductor Software Product R&D at GTRONTEC Dongzhi, stated.

In terms of production automation, the GTRONTEC Dongzhi CIM project will help Gaoxin Technology transition from fully manual operations and record-keeping to managing all process production through the CIM system. For example, the RMS system automatically verifies and controls equipment production programs (Recipe) before production starts to avoid scrap caused by human selection errors or system mishandling; the EAP system will enable data collection between semiconductor equipment and MES.

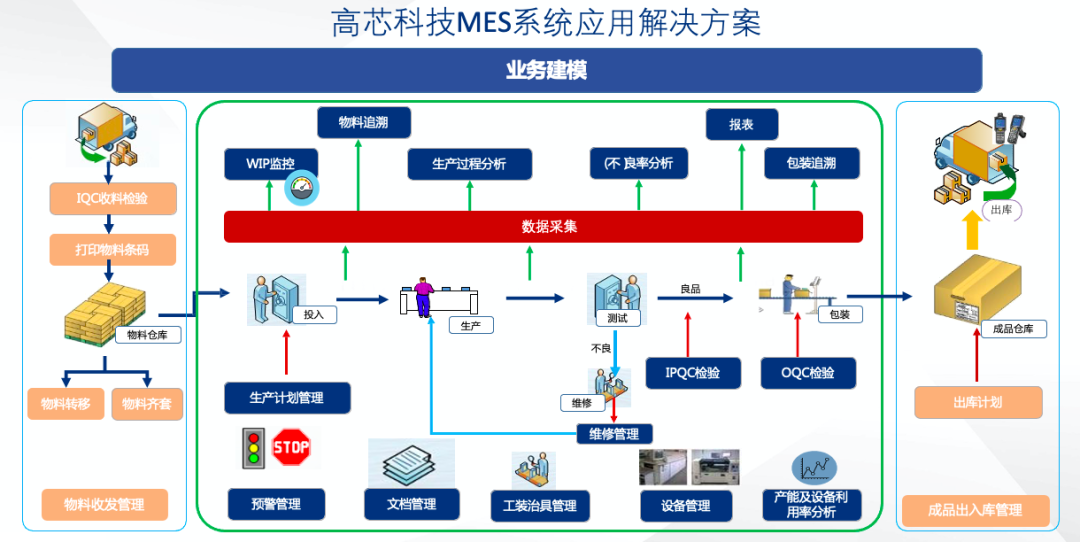

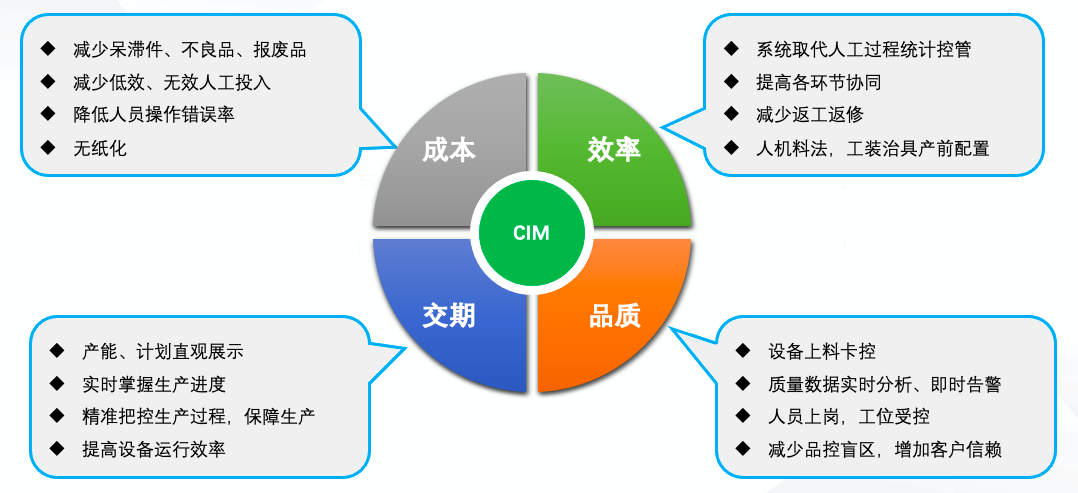

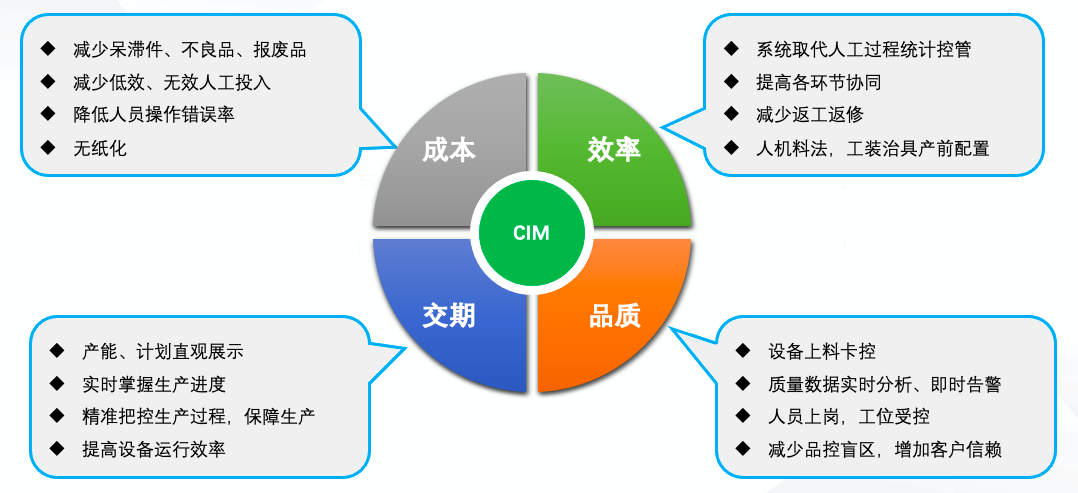

By implementing fine-grained management of the entire production process at the system level, from production lines and workshops down to each step and station's work-in-progress tape-out posting, the CIM system implemented by GTRONTEC Dongzhi will significantly enhance the management level and efficiency of the entire semiconductor factory. Meanwhile, comprehensive paperless production in the workshop not only greatly reduces the manual recording workload for frontline operators but also cuts down on paper documents, lowering production consumption and costs.

In terms of product quality, the GTRONTEC Dongzhi CIM project achieves complete quality control and tracking from incoming inspection, process inspection, warehouse inspection to finished product outbound inspection, as well as OCAP control, through SPC and quality control systems. Additionally, the data middle platform statistically analyzes all production process and quality data, intuitively displaying order production status, equipment OEE, work order material consumption, and work-in-progress and product traceability through electronic dashboards and statistical reports, making production process information transparent.

”

Xu Lei, Chief CIM Consultant at GTRONTEC Dongzhi Semiconductor, pointed out:

“Overall, the CIM system reduces rework and scrap rates of finished products and improves first-pass yield through mistake-proofing and control of the production process, and the quality system's real-time monitoring and response to production quality. At the same time, by integrating order, production, and warehouse information, it shortens delivery evaluation and achieves reduced LOSS and costs, as well as a closed-loop improvement for LOSS.”

As a cross-industry platform originating from China's semiconductor manufacturing industry, GTRONTEC Dongzhi has accumulated a growing semiconductor professional team of over 700 people. It is not only proficient in industrial software and system R&D for cutting-edge manufacturing like semiconductors but also one of the few domestic industry leaders providing full-stack factory integration services. Services range from whole-plant and multi-plant digital consultation and solution design, IT implementation and delivery, to subsequent maintenance. Based on a new perspective of 'production-analysis-prediction', it builds semiconductor industry factory production systems. Its self-developed CIM has industry-leading core technical capabilities and empowerment, supporting more and more industry clients in building advanced semiconductor benchmark factories.

For more product information, please scan the QR code below to obtain