Grasping the New Trend of Smart Manufacturing, GeChuang DongZhi Appears at Guangdong International Industrial Expo

On August 8, the Guangdong International Industrial Expo (hereinafter referred to as Guangdong Industrial Expo), jointly organized by the Mechanical Industry Branch of the China Council for the Promotion of International Trade, the Guangdong-Hong Kong-Macao Advanced Manufacturing Industry Alliance, and the Guangdong Machinery Industry Association, and supported by dozens of leading industry associations from Guangdong, Hong Kong, and Macao, grandly opened in Guangzhou.

This Guangdong Industrial Expo specially set up an "Industrial Internet" exhibition area, focusing on smart manufacturing, and centrally displaying advanced manufacturing technologies and smart manufacturing solutions. GeChuang DongZhi showcased the Dongzhi platform and two newly launched industrial application enabling tools.

1. Empowerment Platform for Frontline Production--Dongzhi Industrial Application Smart Platform

Through in-depth contact with a large number of manufacturing companies, GeChuang DongZhi has summarized two types of problems and challenges companies face in digital transformation: first, data silos in the industrial field that cannot interconnect; second, data is merely presented, and its value cannot be realized.

Addressing the actual pain points of manufacturing, GeChuang DongZhi has created an empowerment platform for frontline production--the Dongzhi Industrial Application Smart Platform. The platform strongly empowers production engineers with three major features: powerful industrial field data collection and processing capabilities, flexible self-service industrial model building capabilities, and built-in rich industrial data analysis and presentation capabilities.

2. Lightweight Agile Data Analysis Tool--Dongzhi Multi-Factor Analysis Tool

When analyzing abnormalities in the production process, the data dimensions are high, factors are chaotic, and there are many types of data abnormalities that are difficult to identify. The "true cause" often involves multiple factors working together, hidden in vast amounts of data.

To solve the confusion faced by engineers, GeChuang DongZhi independently developed the Dongzhi Multi-Factor Analysis product, providing a lightweight, visual, DIY tool for agile multi-factor data analysis in the industrial field, allowing engineers to simply drag and drop to instantly become "industrial geeks."

3. One-Stop Solution for All Work--Dongzhi Mobile Office Collaboration Product

Most manufacturing companies have scattered industrial application systems, with no centralized entry point and lack of synchronization across multiple devices; privately deployed mobile products require large development teams and hundreds of person-days to complete.

Addressing customer needs for security, collaboration, and efficiency, GeChuang DongZhi launched a mobile collaborative office product suitable for industrial manufacturing companies. With one entry point, it handles all work in one stop, quickly locates factory problems, and keeps track of production site conditions at all times.

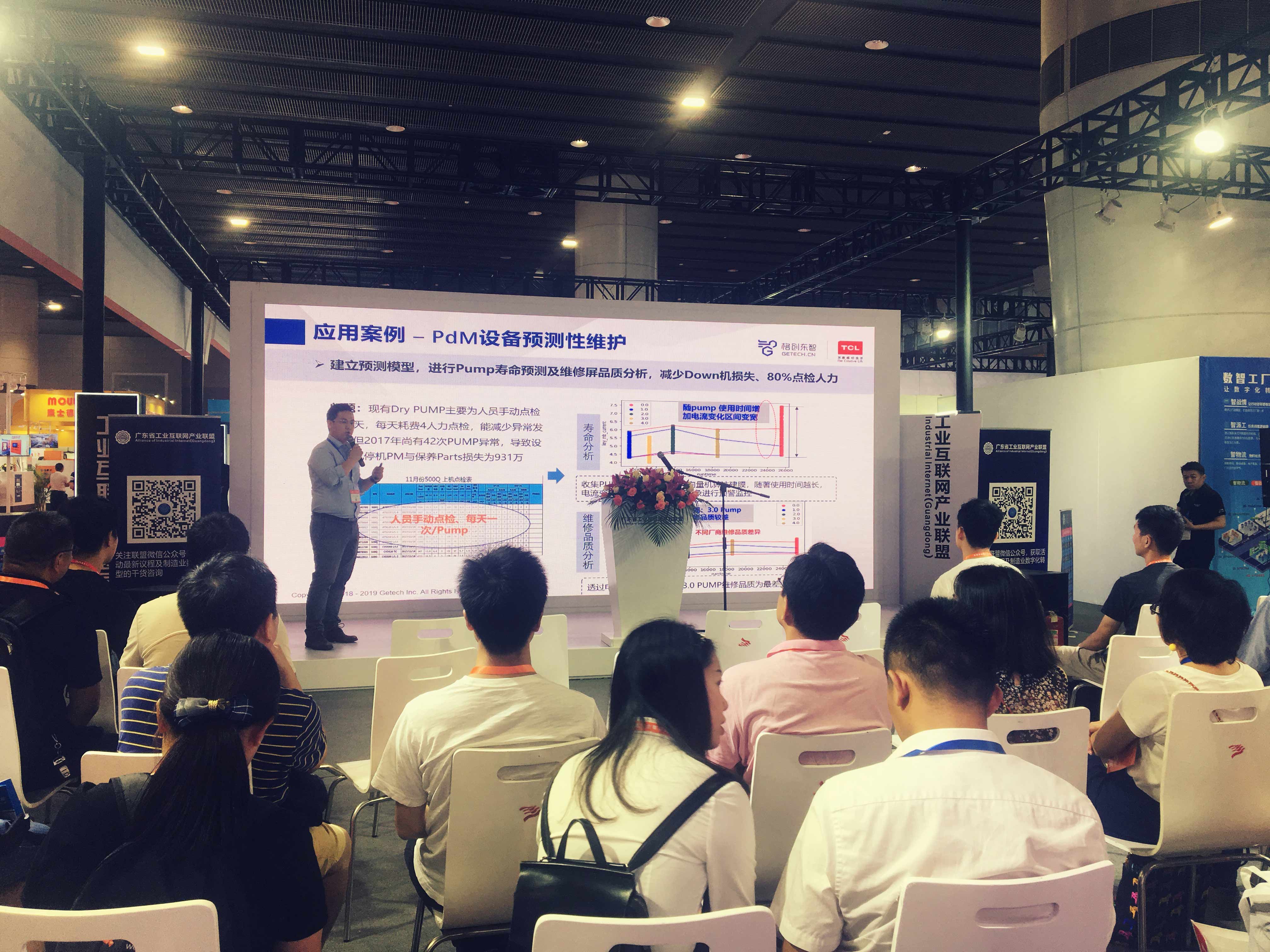

At the Industrial Internet Alliance live show event, multiple industry experts provided suggestions on the development direction and top-level design of China's industrial internet, showcasing the latest industrial internet technologies, products, and concepts. Dr. Li Nan, a senior solutions expert at GeChuang DongZhi, was invited to deliver a keynote speech and share practical cases on site.

Dr. Li Nan shared that the Dongzhi platform is already operating efficiently and with high quality in factories across different industries and production models, such as semiconductors, electronics, communications, and home appliances. Taking China's leading panel company, TCL CSOT, as an example, it achieved a 20% reduction in factory renovation costs, a 10% reduction in quality abnormalities, and a 6-8 times return on investment over three years through the GeChuang DongZhi Industrial Application Smart Platform.

Respecting the industrial field and returning to the essence of the industrial internet. Dr. Li Nan pointed out that GeChuang DongZhi's products cover the entire lifecycle of manufacturing data, from data collection, storage, and full value chain integration to data analysis and value mining. The Dongzhi platform aims to be a tool library for frontline personnel, a data wall for on-site management, and a cockpit for factory management. Through the internal strength of the factory and relying on the company's own new generation of on-site production engineers, it truly implements the industrial internet within the enterprise, helping companies achieve digital and intelligent transformation.