No.1 in the Province! Wuhan Takes the Lead in the 'New Track' of Smart Manufacturing

Changjiang Daily - Changjiang Net, November 17 (Reporter He Liang, Correspondent Wu Jingxuan) Recently, the Wuhan Industrial Intelligent Transformation Promotion and Exchange Conference was held at Wuhan Huapei Power Technology Co., Ltd. It was reported that from January to October, Wuhan's industrial investment grew by 17.2%, ranking first in the province, with industrial technological transformation investment growth reaching 30.3%.

This year, Wuhan has vigorously promoted the "Industrial Enterprise Smart Transformation Action Plan," with maximum rewards for a single enterprise reaching 22 million yuan. So far, Wuhan has collected smart transformation demand information from over 800 large-scale industrial enterprises through the "Smart Transformation Plan," with a total planned investment exceeding 20 billion yuan.

On the same day, GTRONTEC signed a smart factory construction project with Wuhan Huapei, with a total investment of about 250 million yuan, collaborating with internationally renowned companies like Siemens to create a benchmark "Lighthouse Factory" project in Wuhan.

Rendering of the "Lighthouse Factory" (Photo provided by Wu Jingxuan)

Guided by the "Smart Transformation Plan," Wuhan's industrial enterprises have been highly motivated to carry out technological transformations, effectively promoting a new round of growth in the city's industrial technological transformation. In the first three quarters, the city added 283 large-scale industrial enterprises, with total profits of large-scale industrial enterprises growing by 31.4%.

"We are currently in a period of capacity ramp-up, and market demand for our products far exceeds supply, surpassing expectations," Liu Xue, project manager of Wuhan Huapei Power Technology Co., Ltd., told reporters. "This is the first year of production, and we expect to achieve an output value of 300 million yuan next year, with a target of 1.5 billion yuan the following year. Smart factory construction is crucial to achieving this goal."

Enterprises: Smart Transformation Enhances Core Competitiveness

Since the launch of Wuhan's "Smart Transformation Plan," renowned smart manufacturing service companies such as Lenovo Smart, GTRONTEC, Shanghai Mingjiang, Shanghai Electric, and Shanghai Baoxin have settled in Wuhan, strengthening the supply capacity for smart transformation among the city's industrial enterprises.

"Signing with GTRONTEC is based on Wuhan Huapei's actual situation. We hope that through GTRONTEC's professional solutions, Wuhan Huapei can achieve smart upgrades, leading to faster production, increased efficiency, reduced costs, and enhanced core competitiveness," said Wu Huailei, chairman of Huapei Power Group, at the signing ceremony.

Wuhan Huapei's factory is located in the Wuhan Economic and Technological Development Zone, producing key components for turbochargers, which are core parts of automotive engines. Currently, the factory's wastegate components hold about 25% of the global market share.

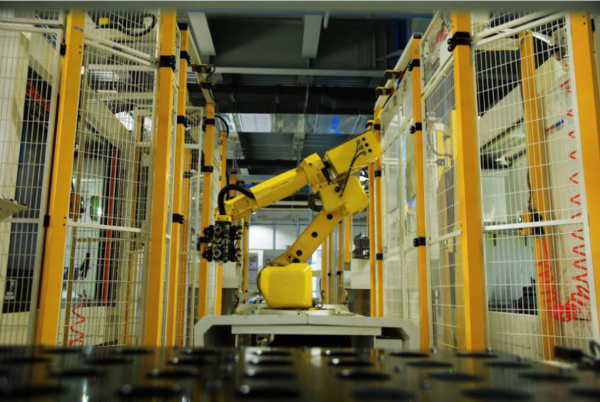

Smart Manufacturing "Lighthouse Factory" built by GTRONTEC and others in Wuhan (Photo provided by Wu Jingxuan)

It is reported that Wuhan Huapei's smart transformation project is expected to invest about 250 million yuan, with funds primarily used for workshop intelligence and informatization construction.

Experts: Enterprises Need to "Catch Up" on Smart Manufacturing

Zhao Xusheng, General Manager of the Smart Manufacturing Center at China Zheshang Bank's Corporate Banking Department, believes that manufacturing enterprises nationwide face obstacles such as lack of direction, technology, funds, and services in smart transformation, leaving many enterprises uncertain in the face of the global smart manufacturing trend.

"Conventional corporate loans cannot meet the needs of smart transformation," Zhao Xusheng analyzed. "Smart transformation requires long investment cycles and large amounts of capital. Enterprises hope to see quick results to enhance competitiveness and expand sales, but multiple uncertainties about expectations cause hesitation."

"Wuhan's industrial smart transformation is not change for the sake of change but is focused on improving production efficiency," said Liu Jiafeng, Smart Manufacturing Business Director at GTRONTEC, who has been stationed in Wuhan for the past six months. After visiting dozens of Wuhan factories, he told reporters that, compared to coastal areas, Wuhan enterprises need to "catch up" on smart manufacturing.

Liu Jiafeng stated: "Smart manufacturing is not a cure-all. Blindly adopting advanced equipment will not achieve the desired goals. Enterprises need a clear understanding and overall strategic planning for smart manufacturing."

Since Wuhan fully launched the "Smart Transformation Plan" this year, GTRONTEC, as one of the top national service providers, has participated in and provided diagnostic services for 54 enterprises. Through pilot demonstrations, it has covered sectors such as pharmaceuticals, automotive parts, heavy equipment, smart home appliances, LCD panels, and light industry in Wuhan.

Goal: Striving to Become a High-Quality Manufacturing Development Demonstration Zone

Zhao Xusheng commented that Wuhan has established a "one-stop" service platform for industrial enterprises' smart transformation, from diagnostic consulting to financial support, putting it ahead of the nation.

As one of the earliest institutions to launch specialized financial products for "smart manufacturing," China Zheshang Bank has joined as a professional financial institution in the service consulting platform. So far, it has provided 5 billion yuan in credit for smart transformation projects of 26 enterprises in Wuhan.

To date, five municipal platform institutions, including GTRONTEC, have diagnosed 210 enterprises in batches, issued 70 diagnostic reports, and signed project agreements totaling 2.16 billion yuan.

It is reported that the diagnostic consulting work for the first batch of 158 enterprises will be completed by the end of the year, providing targeted solutions and full-chain services. The plan is to create 10 lighthouse projects and 25 demonstration projects across industries and fields, while progressively advancing 100 typical projects.

An official from the Wuhan Municipal Bureau of Economy and Information Technology stated that Wuhan is striving to become a new first-tier city, which must be supported by world-class industrial clusters. As an important industrial base in China, Wuhan is using the "Smart Transformation Plan" as a key approach to build world-class industrial clusters and strive to become a national demonstration zone for high-quality manufacturing development.

Article reprinted from: Changjiang Daily