Behind TCL Huaxing Optoelectronics' global No. 1 shipment of LCD panels, what did IoT x AI do right?

In February 2020, based on shipment volume, TCL Huaxing Optoelectronics (CSOT) became the world's largest LCD TV panel supplier for the first time with an 18.8% share; based on shipment area, TCL Huaxing also ranked first with a 19.6% share. Behind these exciting numbers for Chinese manufacturing, we found IoT x AI and manufacturing's deep integration has begun to show results.

Data source: CINNO Research

As a leading global semiconductor display company, Huaxing Optoelectronics has fully deployed smart manufacturing since its establishment. It scientifically applies industrial internet technologies: IoT platform, big data platform, AI, basically achieving software and equipment interconnection, equipment and environment mutual perception, making factories more digital and intelligent.

Connection and Data

"Huaxing's products go through nearly 40 processes, each product needs to control about 25,000 parameters in these processes, and over 2TB of production data is generated and collected daily."

Huaxing Optoelectronics widely uses IoT technology, with tens of thousands of IoT points, real-time solving communication coordination of people, machines, materials, methods, and environment. IoT technology breaks data black boxes, automatically reporting data like material/power energy consumption even in seconds, doing simple computing at edge nodes, and uploading more valuable data to the platform.

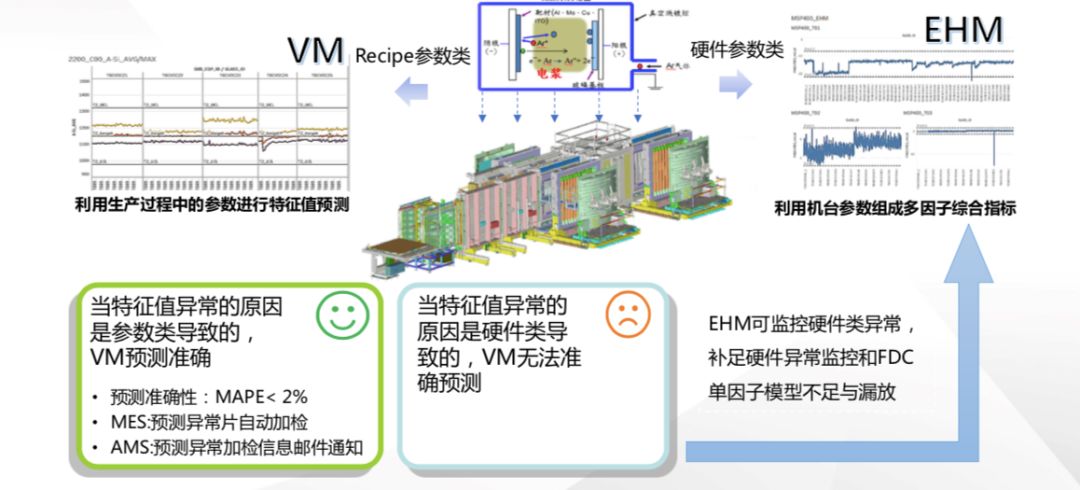

Data collected by IoT can be analyzed through big data platforms and imported into deep learning algorithms, using equipment and process parameters to achieve fault prediction. Using data for equipment component life prediction, conducting predictive maintenance, reducing failure rates.

<极速>

Quality Control

"The panel industry has high investment, expensive equipment, and high product costs, so we reduce costs from all aspects while pursuing极致 yield to lower loss costs; with trends like high规格 diversity in the panel industry, we face greater cost and yield challenges."

In quality control, Huaxing Optoelectronics uses big data analysis tool MFA (multi-factor analysis), achieving virtual measurement solutions. Virtual measurement quickly finds abnormal factors through independent and dependent variable analysis modules,提前 judging production process data to predict product characteristic values, achieving real-time full inspection. This small application quickly reduced product inspection quantity, shortened production cycles, and improved yield rates.

Visual Inspection

"There are nearly 100 inspection stations in the entire production process,其中 optical and lighting stations need to judge over 2 million images daily, requiring大量 manpower."

In finished product quality inspection, Huaxing Optoelectronics pioneered AI automatic defect classification technology, automatically identifying defects, judging quality, and handling abnormalities. Compared to traditional manual methods, AI recognition speed increases 10 times, shortens production cycle by 40%, reduces manpower by 50%, fully ensuring the quality of each panel product.

Huaxing Optoelectronics uses smart factories as carriers to achieve full-process intelligence, based on end-to-end data flow, supported by network interconnection, using industrial internet to control production processes, improve product quality, reduce equipment maintenance, and increase personnel productivity.

In the process of Huaxing Optoelectronics building leading smart factories and pursuing极致 quality, GTRONTEC accompanies it. Looking forward,更多 Chinese manufacturing enterprises achieve "global first" with technology assistance.