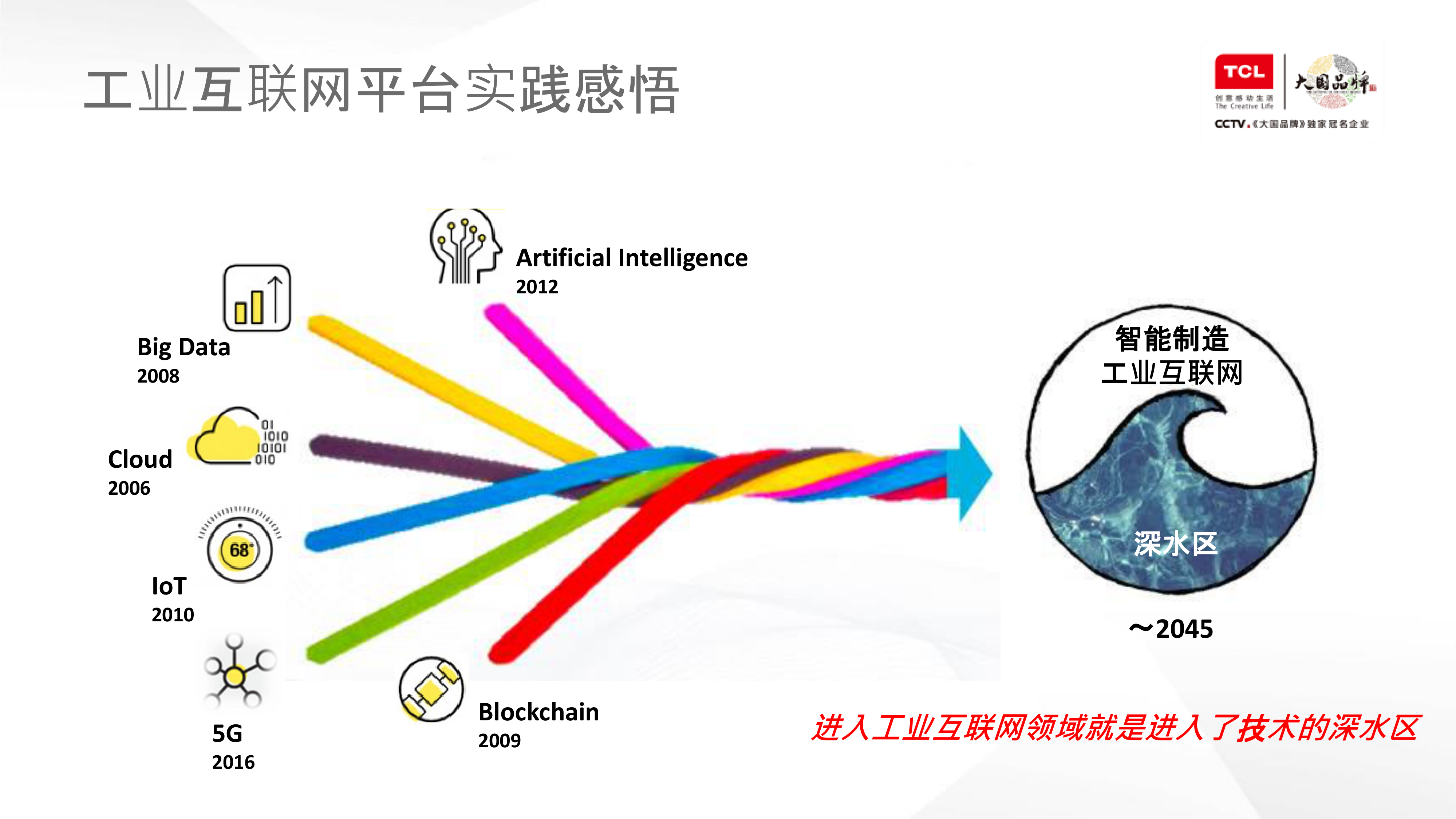

From Industrial Internet to Industrial Application Intelligence — The Evolution Direction of Industrial Internet

[Dr. Wang Jin] Chief Smart Manufacturing Consultant of GTRONTEC

GTRONTEC Technology is an industrial internet company incubated by TCL. TCL's nearly forty years of manufacturing history, continuous and discrete manufacturing models, and production bases worldwide provide the best foundation for the R&D and implementation of industrial internet.

| China's New Infrastructure and Industrial Internet Development Direction

In 2020, industrial internet was listed as one of the seven major areas of new infrastructure along with 5G, big data centers, artificial intelligence, new energy vehicle charging piles, ultra-high voltage, and intercity high-speed rail and intercity rail transit.

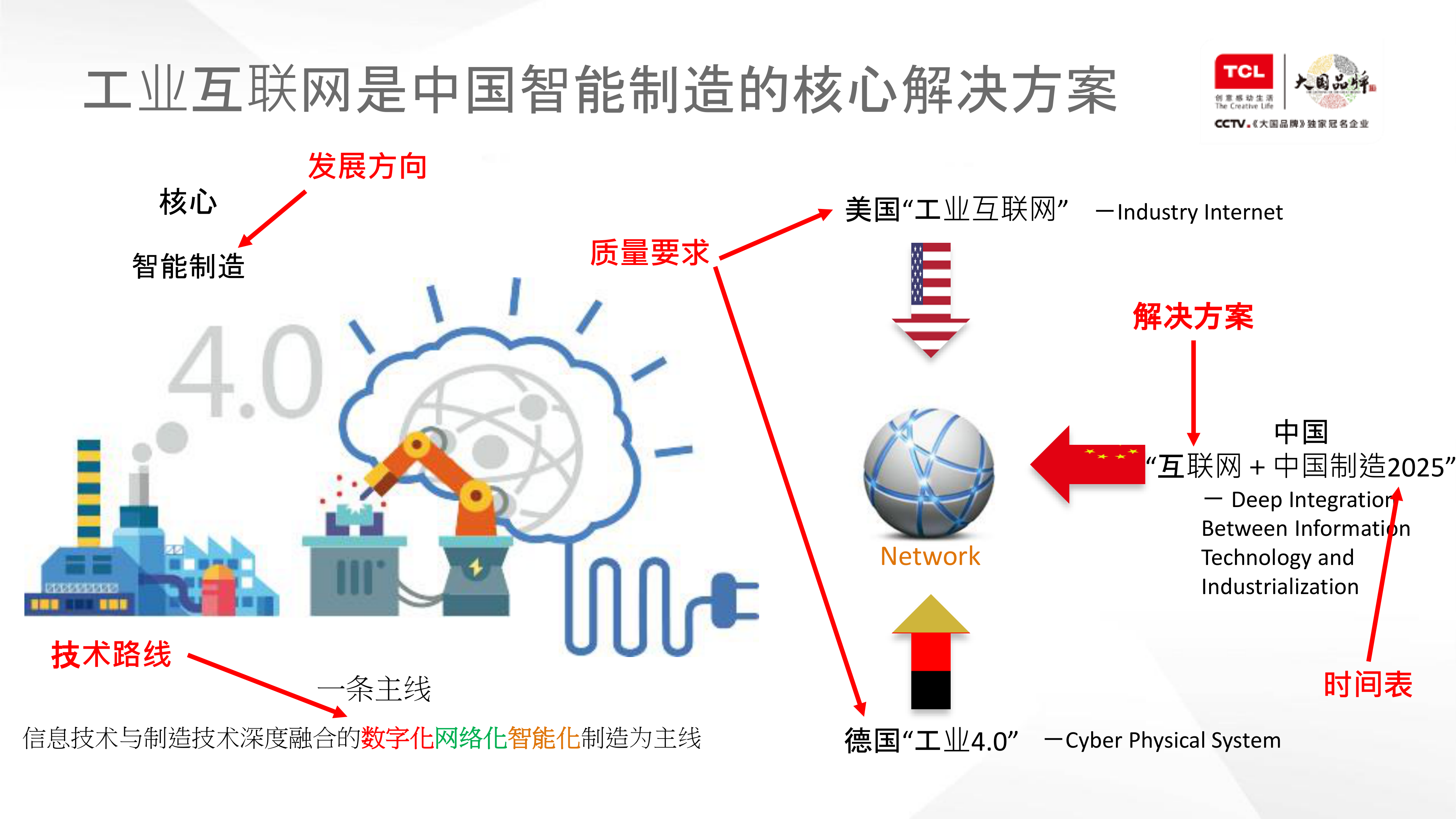

This is undoubtedly exciting news for industrial internet industry professionals. In Dr. Wang Jin's view, industrial internet is the core solution for China's smart manufacturing. Recently, Dr. Wang Jin was invited to share his views and outlook in Tencent's Industrial Public Welfare Course.

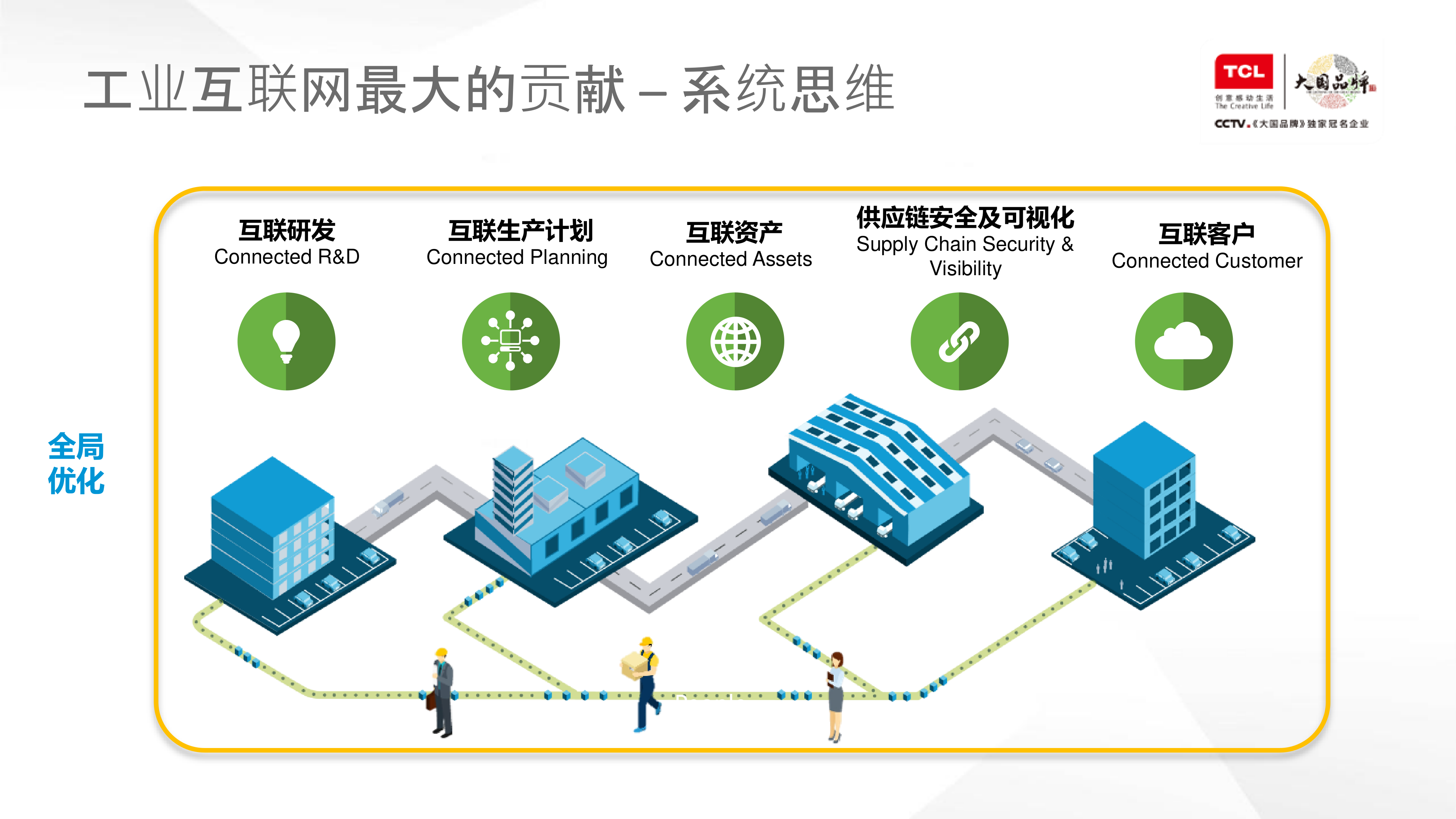

| The Greatest Contribution of Industrial Internet - Systems Thinking

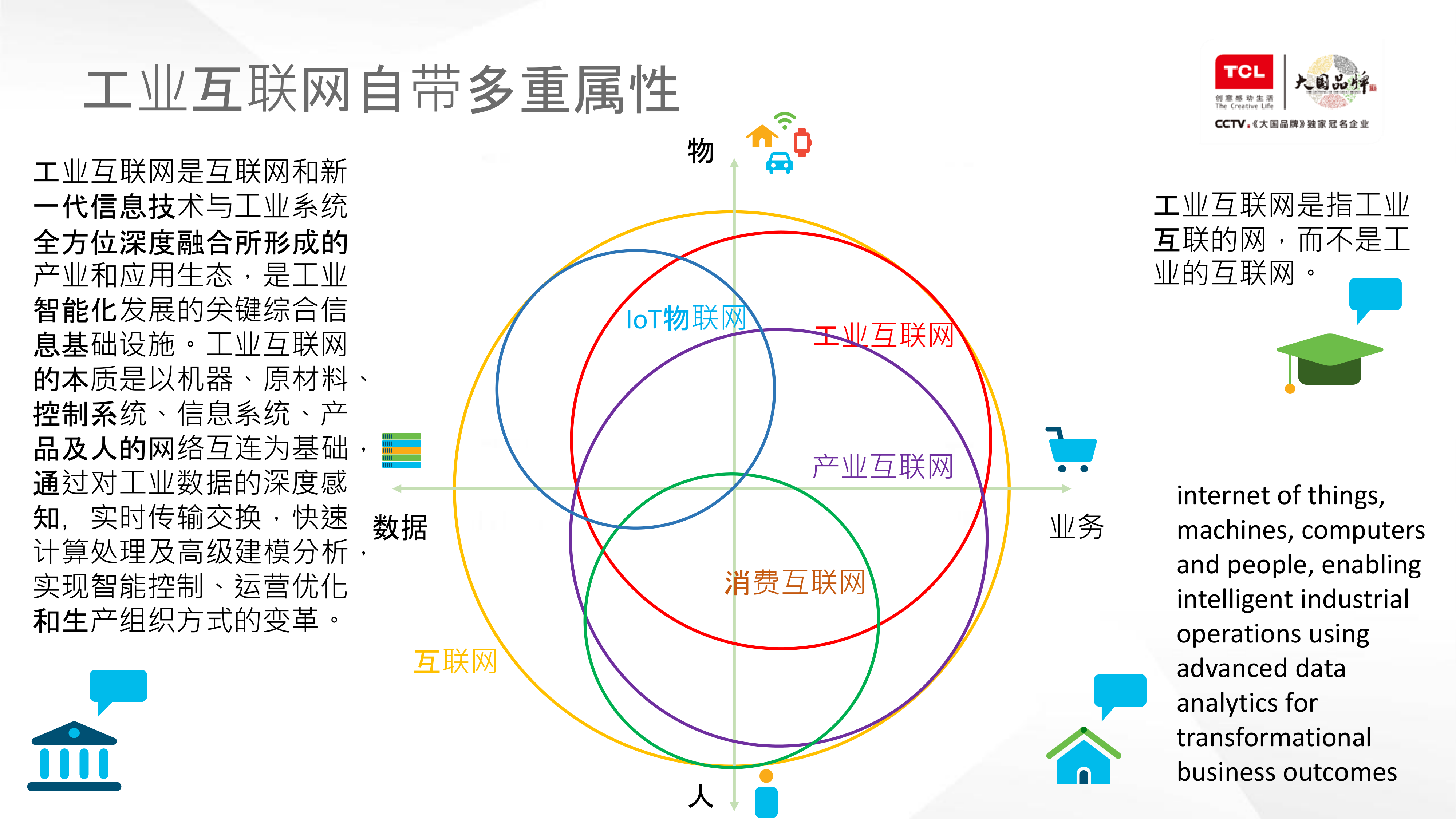

China's industrial internet inherently has multiple attributes. In the past, whether we developed application systems, functions, or solved technical problems, we essentially did local optimizations. Industrial internet requires us to extend from a local perspective to a systems perspective.

This is the greatest value that industrial internet brings us. The platform effect brought by industrial internet is very critical. For example, to sustain life, we need to eat. If you are in the wild, you need to hunt, set up a stove, light a fire, and roast a rabbit. But in a kitchen, it's different: fire, oil, and ingredients are at hand, and you can quickly serve a dish. Similarly, with an industrial internet platform, its value is such that it quickly solves a problem for customer enterprises and provides a solution.

| Value Positioning of Industrial Internet Platform: Data-Driven Intelligence Under Widespread Connectivity

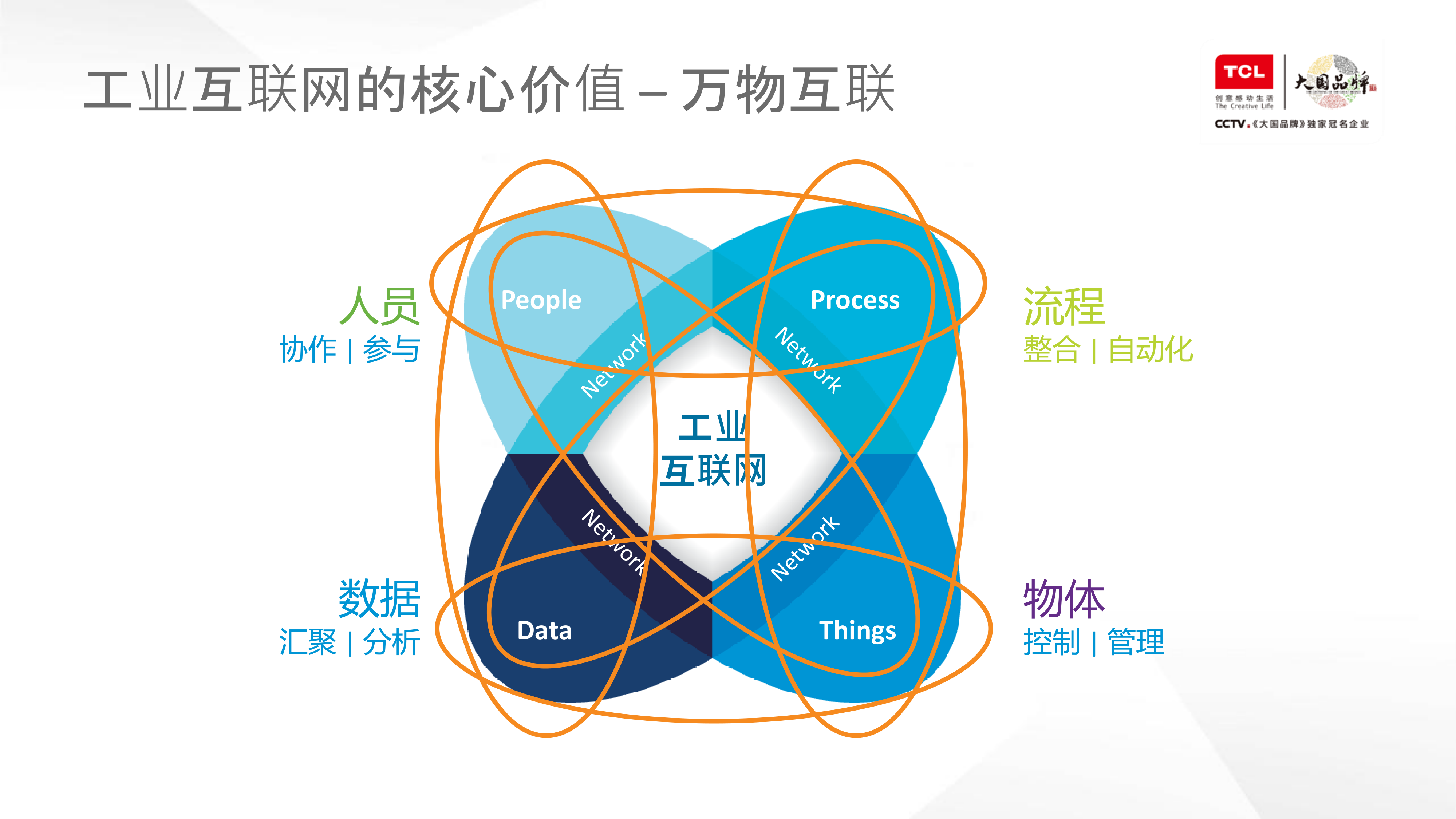

Industrial internet connects everything, generating vast amounts of data. We try to extract more high-value information from low-value data; we try to solve major problems of industrial system integration through network extension.

In the process of solving these problems, we gradually deepen our understanding of data and intelligence. In one sentence: data-driven intelligence under widespread connectivity is the value positioning of industrial internet. After grasping this, we have a clear basic direction for doing AI and building platforms, which also guides the development direction of GTRONTEC's Industrial Application Intelligence Platform.

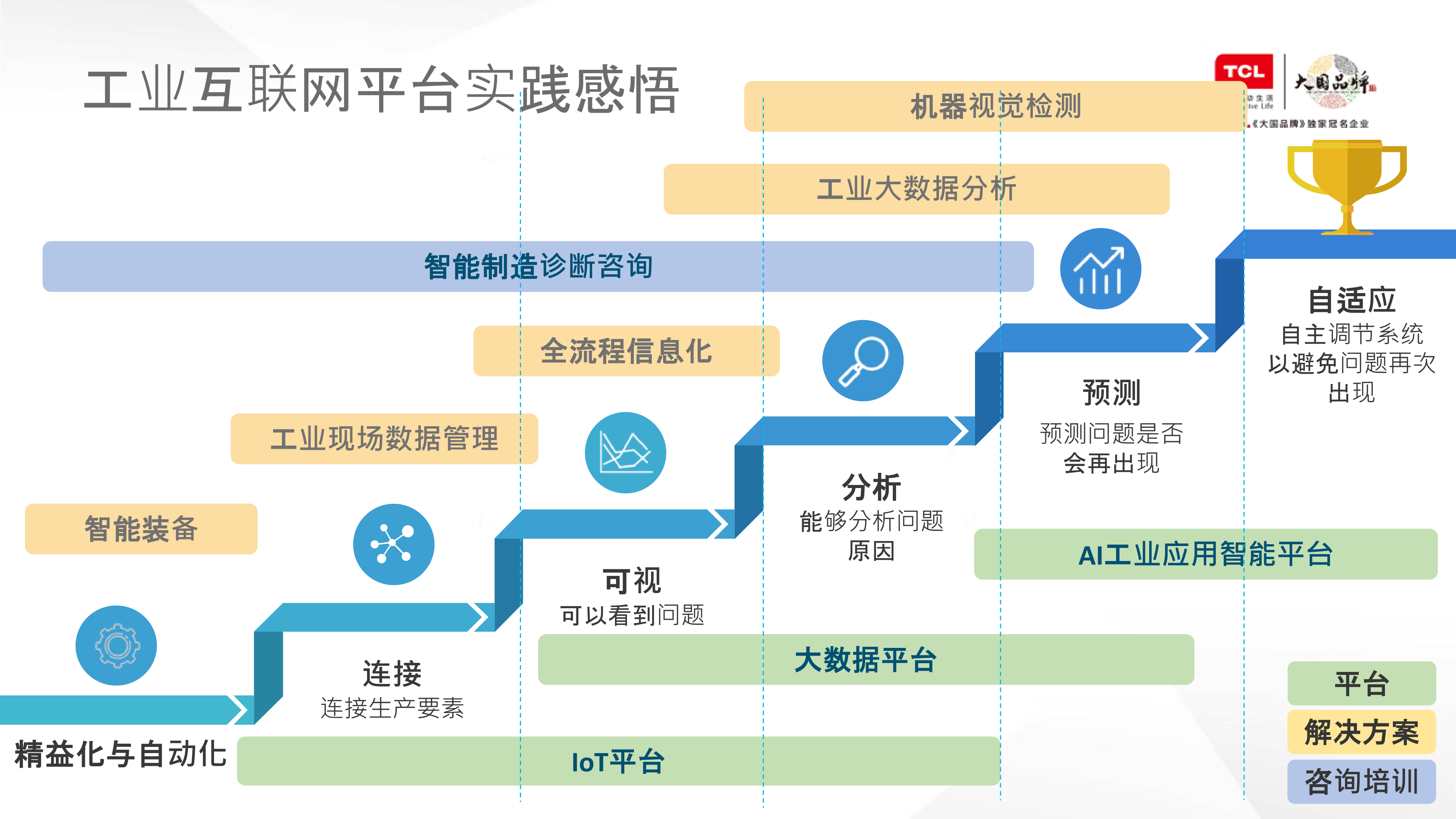

| Platform Evolution Direction: Industrial Application Intelligence Platform

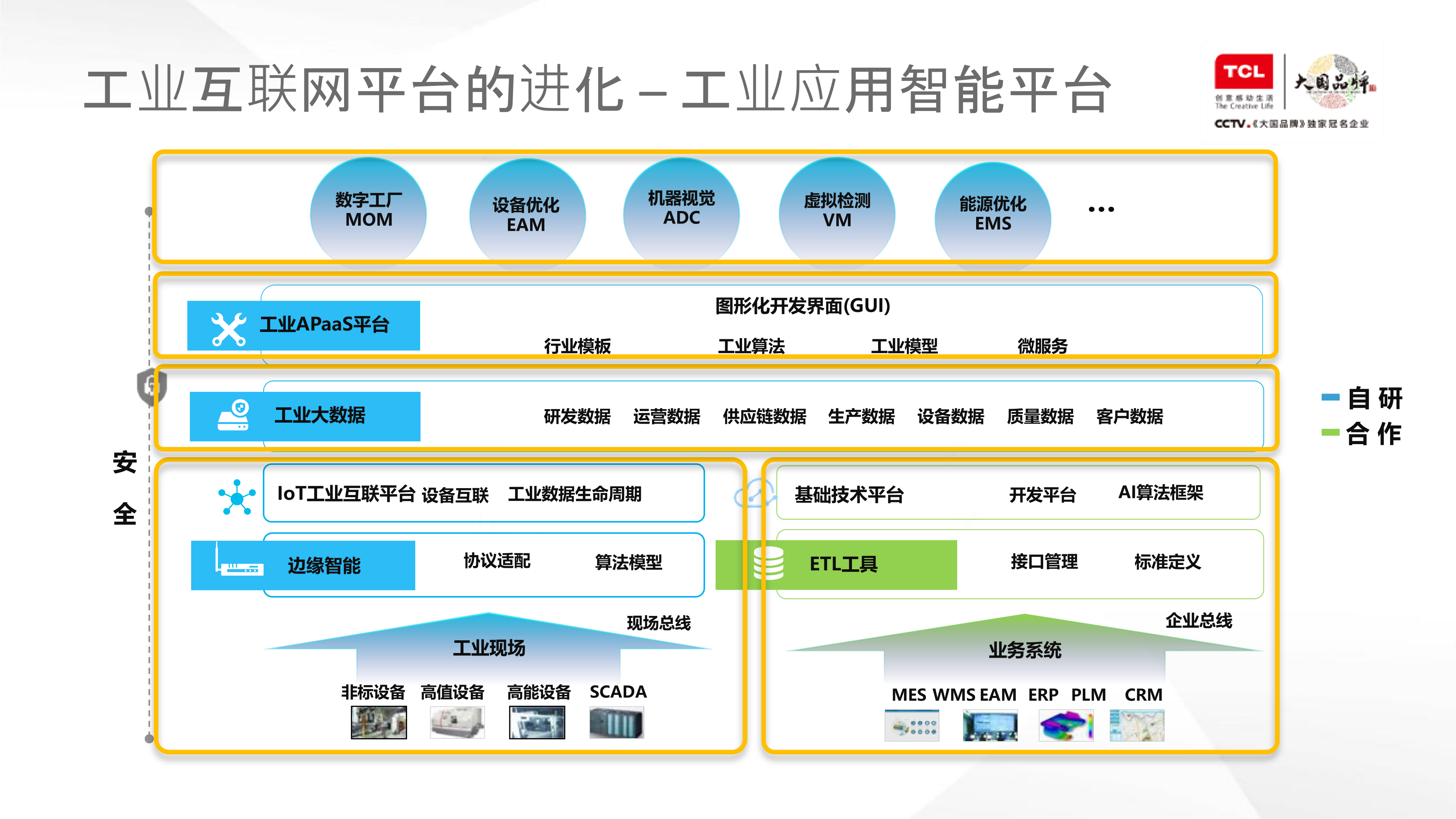

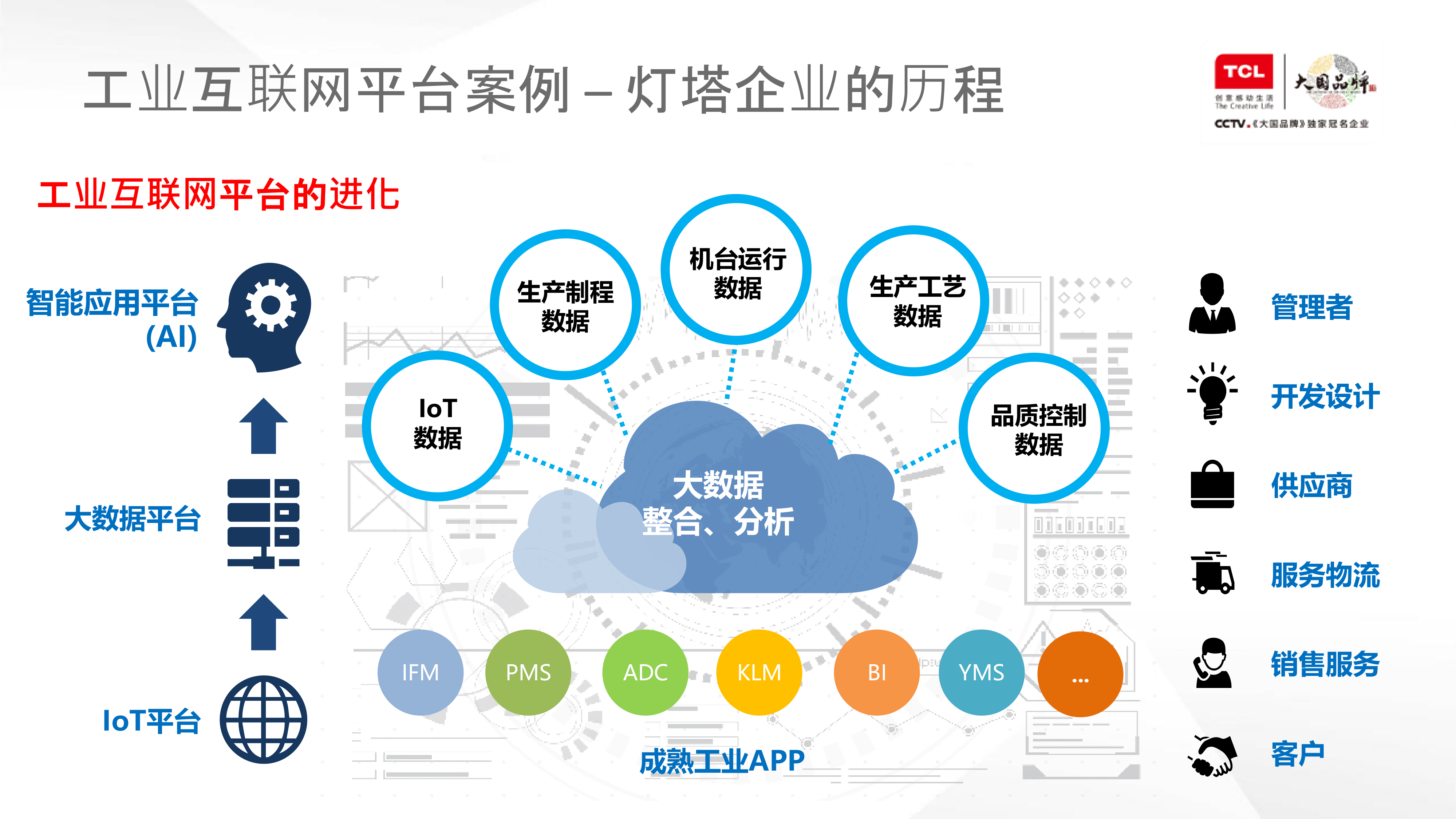

We use the evolution history of GTRONTEC's industrial internet platform to illustrate this. Due to TCL's 40 years of overall smart manufacturing strategy experience and TCL's extensive industrial scenarios, the platform quickly evolved into an Industrial Application Intelligence Platform.

Initially, we built an IoT platform to aggregate data; the need to analyze data led to a big data platform; hoping to generate value from data and apply it to actual production, we developed an APaaS (Industrial Application) Intelligence Platform. On the Industrial Application Intelligence Platform, it supports many practical work applications; in the future, we will build more scenarios and provide more development environments to support the evolution of the Industrial Application Intelligence Platform. We aim to create a platform where enterprises can quickly use the platform, data, and network to solve their own problems and quickly bring value to themselves.

| Industrial Internet Case Sharing

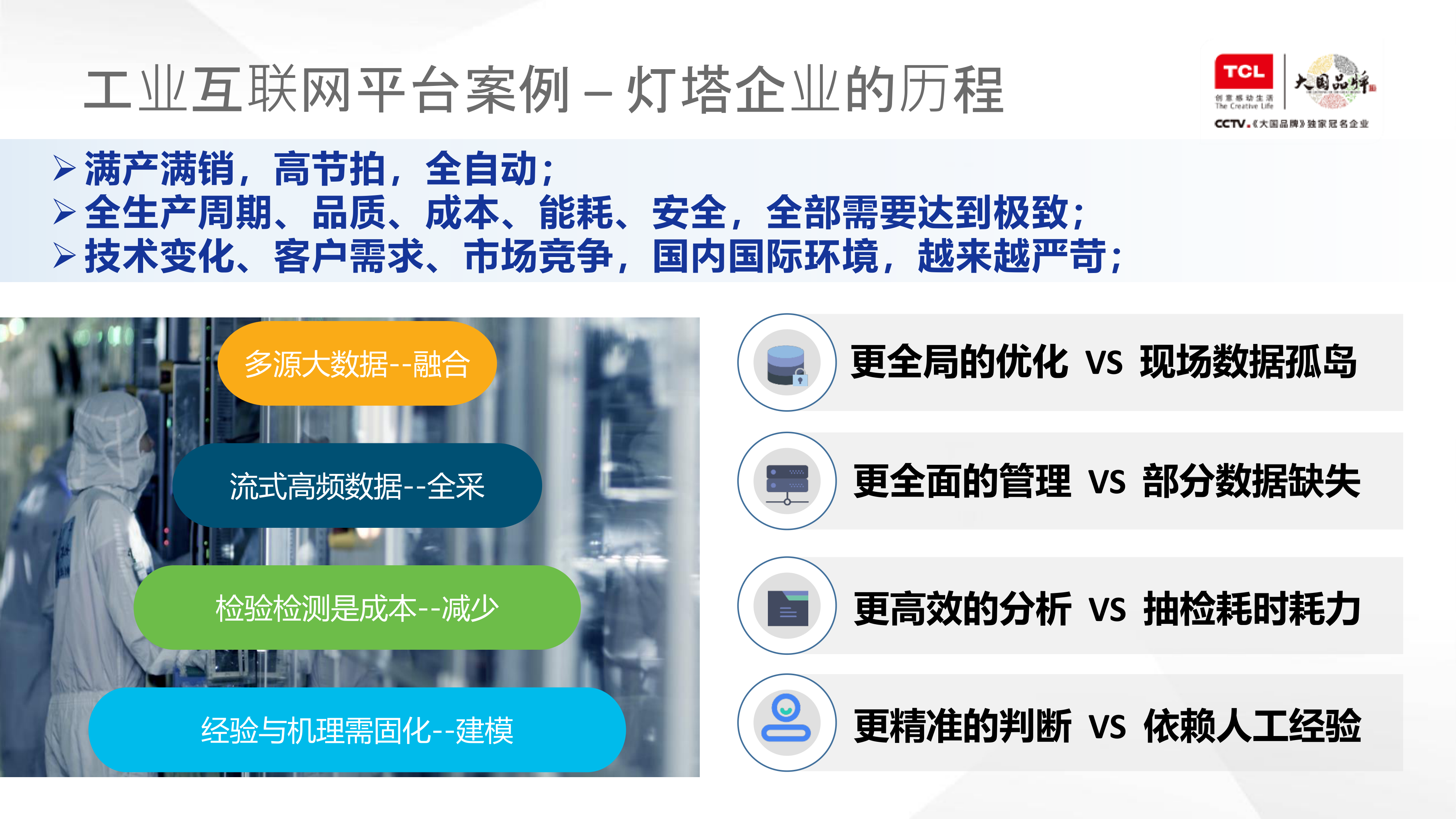

I share a case of a lighthouse enterprise using industrial internet to improve product quality, reduce equipment maintenance, and increase personnel productivity. Industrial internet implemented multi-scenario landing solutions in this enterprise, bringing about 30 million yuan in annual benefits. More importantly, active practice on industrial internet helps the enterprise face challenges such as rapid technological updates, changing customer demands, and intensified domestic and international market competition more calmly.

This customer is a leading LCD panel enterprise with a good foundation in informatization and automation. GTRONTEC did the following for it:

First, build an IoT platform to interconnect more devices, connect high-value collection equipment, use edge computing to fully collect more data, collect more data through industrial internet methods, speak with data, even high-frequency collection up to 20Hz.

Second, build equipment predictive maintenance models. Based on past experience, predictive maintenance is more valuable for some industrial general parts and common parts, so Dry PUMP was chosen because its failure can cause significant impact, and the enterprise has many Dry PUMPs, consuming daily manpower for inspection. Predictive analysis was done on related Dry PUMPs, including life analysis and maintenance quality analysis, overall improving the stable state of Dry PUMPs, ultimately reducing unplanned downtime losses and 80% inspection manpower.

Later, we incubated MFA (Multi-Factor Analysis Tool) in the usage scenarios provided by the customer. Through independent and dependent variable analysis modules, quickly find abnormal factors, becoming the basis for many of our solutions. For example, the virtual measurement solution implemented with MFA addresses issues like high cost and lagging results in product quality inspection. Using MFA to make early judgments on production process data predicts whether products on the production line meet quality requirements. If within a certain data range, we believe this batch of products can skip sampling inspection. This small application quickly reduced the number of enterprise inspections, shortened the production cycle, and improved the yield rate.

AI has also achieved good application effects in AOI inspection and judgment scenarios. Originally relying on manual optical inspection, using Gechuang Tianshu AI system achieved automatic judgment replacing manual judgment, quickly completing defect discrimination for all products.

Our results from both theory and practice are consistent: smart manufacturing is a clear climbing process, with different platforms supporting each step. In the early stage, IoT platforms with increasing data volume; then data processing capabilities become a big data analysis platform; finally, moving towards intelligent development. China's industrial internet must take the path of Industrial Application Intelligence Platform.

In the process of adhering to the R&D and construction of the industrial intelligence platform evolution direction, we have many insights. I hope these insights inspire the entire industry and accelerate the evolution speed of the industrial internet industry. Instead of solely emphasizing big data, which brings huge pressure and cost risks, we should find ways to make optimal decisions under limited information conditions. GTRONTEC developed MFA based on "practicality"; for industry, we must use industrial thinking to build industrial application platforms and systems, conform to OT habits, be simple to operate, without needing API development, which is what GTRONTEC insists on: simple, efficient DIY, more flexible.

The core value of industrial internet lies in taking the path of digitalization, networking, and intelligence. In the interaction process, the network naturally unleashes its huge value! Now encountering such a good opportunity with new infrastructure, let us all participate together and open the spring of industrial internet bull market.