Generating nearly 10 million in benefits annually, what's the magic behind GeckMind, the factor analysis modeling tool by Gektrion?

When facing industrial data that is large in volume, high in dimensionality, and complex in relationships, manufacturing companies often encounter issues such as limited analysis methods, low efficiency in multi-dimensional data analysis, and a shortage of data mining talent. The factor analysis modeling tool introduced today can effectively address these challenges.

In the wave of new infrastructure, digitalization and intelligence are highly expected to help manufacturing companies combat the pandemic, improve efficiency, and reshape competitiveness. Companies hope to enhance the agility, flexibility, and sustainability of their operations through digitalization and intelligence, while also focusing on practical results due to cautious spending.

Against this backdrop, TCL Gektrion, a leading domestic provider of industrial internet platforms, launched the GeekMind factor analysis modeling tool. It focuses on improving product quality, quality prediction, and equipment predictive maintenance, delivering excellent application results in implementing enterprises. GeekMind won the 2019 Industrial Internet Alliance Outstanding Industrial APP Award.

| 1. GeekMind Modeling Tool: AI + Big Data Analysis to Enhance Product Quality

In the product manufacturing process, the "true causes" affecting product quality are single or multiple factors in the production process working together. However, when facing industrial data that is large in volume, high in dimensionality, and complex in relationships, manufacturing companies often encounter issues such as limited analysis methods, low efficiency in multi-dimensional data analysis, and a shortage of data mining talent. Gektrion's GeekMind factor analysis modeling tool can effectively address these challenges.

Click the video to watch

| 2. GeekMind Acts as a Magician, Reducing Defective LCD Panel Units from Batches to Single Pieces

The production process of LCD panels is numerous and complex. Each process can cause quality deviations due to various sources of interference. To ensure product quality, it is usually necessary to test key parameters of each in-process stage to ensure the process meets standards. However, since some tests cannot be completed in real-time on the production line, sampling is used for offline measurements. This can lead to delayed detection of defective products, resulting in batch rework or scrap, along with high resource and cost waste.

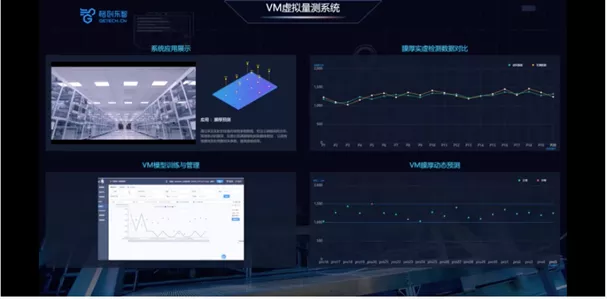

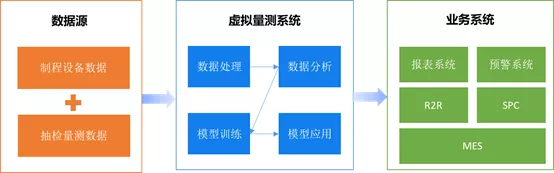

CSOT, a globally leading LCD panel manufacturer, has exceptionally stringent requirements for product quality. In 2019, CSOT adopted Gektrion's GeekMind factor modeling tool to build a virtual measurement system: collecting and summarizing data from multiple processes and defective products, and using GeekMind's rich algorithms and models to quickly and accurately identify the relationship between key indicators and numerous process data from vast amounts of data. The system not only virtually "measures" quality in real-time online but also integrates with the MES system to achieve real-time fault warnings, batch control, and other functions, minimizing the possibility of batch anomalies.

Figure 1: Gektrion Virtual Measurement System

Figure 2: Virtual Measurement Application Architecture

By using GeekMind to build models, the virtual measurement system reduced the defective unit of LCD panels from batches to single pieces. In just one year, it brought CSOT benefits worth millions of yuan.

| 3. Acting as an "Algorithm Engineer," GeekMind Helps Yuxin Thermal Management Improve the Yield of Automotive Heat Exchangers

As a professional manufacturer of automotive air conditioning products under China's AVIC Xinhang Group, Yuxin Automotive Thermal Management Technology Co., Ltd. (hereinafter referred to as "Yuxin Thermal Management") uses brazing furnaces to produce automotive heat exchangers. Fluctuations in the yield during the brazing process have a certain impact on production efficiency and product quality.

Adjustments to the automotive heat exchanger production process rely on the experience of process experts/technicians, which can vary. Simply introducing algorithm engineers can lead to difficulties in effectively analyzing production parameters due to a lack of understanding of the production process. Digital solutions have become a powerful tool to resolve this contradiction. Yuxin Thermal Management, in collaboration with Gektrion, is about to launch the "Core Workshop Brazing Furnace AI Project" based on GeekMind. GeekMind acts as an invisible "algorithm engineer," helping process engineers use algorithm models to monitor, warn, and optimize equipment process parameters, thereby improving product quality and efficiency.

Specifically, by applying GeekMind, an analysis model for brazing furnace equipment was established for Yuxin Thermal Management. Based on the SCADA system, the relationship between brazing furnace welding process parameters and yield was analyzed, and the comprehensive fluctuations of multiple factors before and after the occurrence of defective products were compared, providing reference for process technicians. Moreover, after the model is deployed, it can achieve intelligent self-adjustment and continuous optimization, maximizing product yield.

It is reported that the project will be carried out in three phases, ultimately building an analysis system for Yuxin Thermal Management that can independently model and apply to all types of factory equipment, helping process personnel from various production lines independently complete the entire modeling process, monitor the entire production cycle of products, and ensure high product quality.

As a multi-factor mining and modeling product for industrial sites, GeekMind features rich algorithms, lightweight design, and visualization.

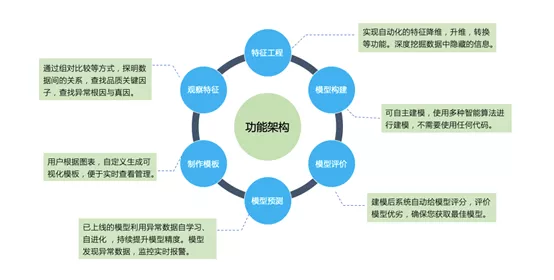

Figure 3: GeekMind Functional Architecture

In terms of functional architecture, GeekMind is divided into six layers: data preprocessing, feature mining, model building, model management, online prediction, and project management. It enables automated data preprocessing, feature dimensionality reduction, transformation, etc., and can use existing machine models for parameter tuning, modeling, optimization, as well as online analysis, monitoring, and warning of anomalies. The model management and project management functions allow users to review any modeling node and manage cases and models uniformly by project.

GeekMind combines the modeling experience of algorithm engineers with the process experience of production engineers, helping companies instantly identify key factors affecting production and quality anomalies, and easily achieve digital solutions such as quality analysis, quality prediction, and equipment predictive maintenance. It requires no programming or redeveloping models, allowing frontline engineers to operate it quickly and simply.

Currently, GeekMind has been applied in industries such as semiconductors, 3C electronics, communications, and automotive parts, achieving outstanding results. If your company is also facing these issues, you are welcome to start by learning about GeekMind.

Contact Gektrion to apply for a GeekMind experience and have the opportunity to receive free production problem consultation and diagnostic services.

Website: www.getech.cn

Phone: 400-600-2869