Industrial Geek Competition: Gotion Smart's Golden Idea Contest Season 1 Winners Announced, Let's Explore the Mysterious 'Industrial Geek'

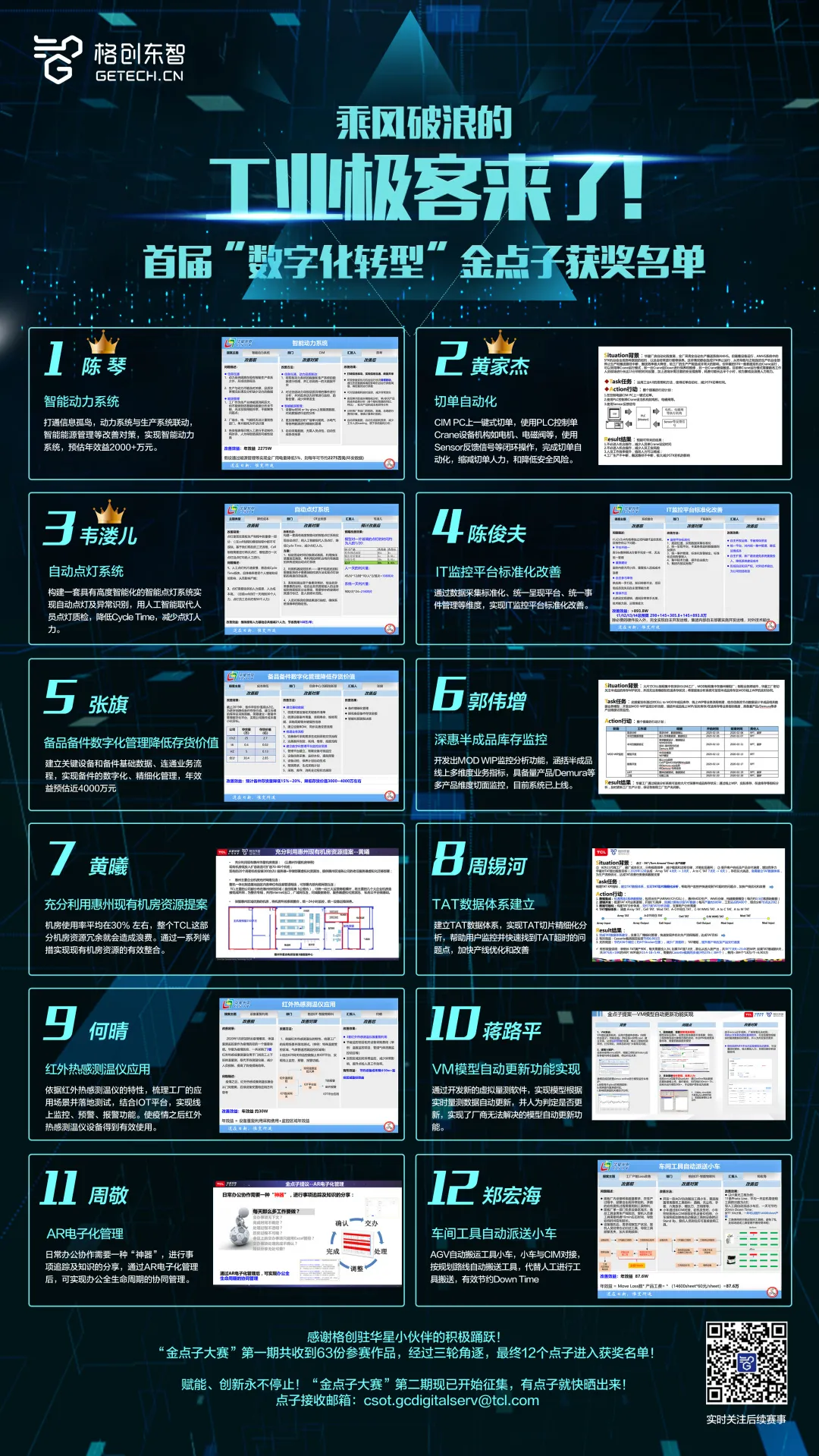

Industrial Geek Competition: Gotion Smart's Golden Idea Contest results are out. This competition received a total of 63 proposals, and after 3 rounds of intense competition, 12 proposals won awards.

▲Winners List

To better train the capabilities of Gotion Smart's digital team stationed at Huaxing, and to continuously create value for Huaxing, we launched the 'Industrial Geek Competition Golden Idea Contest' (hereinafter referred to as the Golden Idea Contest) in February: to find innovative solutions that play a role in promoting the digital transformation of the industry. Through this award selection, we aim to discover good ideas and Gotion people with the industrial geek spirit, making the industrial geek spirit the driving force for Gotion's development.

Gotion Smart firmly believes that the power for manufacturing to transform into 'smart' manufacturing comes from within manufacturing enterprises. It is crucial to create simple and efficient tools and platforms for frontline engineers in manufacturing enterprises, helping production engineers become 'Industrial Geeks'. Those frontline production engineers who dare to innovate and pursue progress, even without an IT background, use Dongzhi Industrial Application Intelligent Platform to develop applications, accumulate models, and build algorithms, turning knowledge, experience, and ideas into enterprise productivity.

Corresponding to the product philosophy of empowering industrial geeks is a code of conduct that is simple and fun, innovative and excellent, and daring to think, strive, and take responsibility. While extreme innovations that颠覆 the era are spectacular, integrating one's observations and thoughts into daily micro-innovations may yield greater value.

So, what exactly is an industrial geek? To explore this, we invited three winners: Chen Qin, Wei Louer, and Huang Xi, to discuss and unveil the mystery of industrial geeks.

Industrial Geeks must be simple and efficient

Chen Qin, head of the machine automation section in the computer-integrated manufacturing department of Gotion Smart stationed at Wuhan Huaxing, believes, "Industrial Geek originates from Gotion Smart's product philosophy: simple, efficient, and DIY. Simplifying complex things, streamlining繁琐 processes, and ensuring that tasks can be completed simply and efficiently is what industrial geeks pursue."

"Data from the power system has never been linked with production system data; quality anomaly analysis lacks power data. Energy consumption is a major expense for factories, and精细 management of energy is urgent. Based on this consideration, we quickly decided on the idea of building a 'smart power system': first, break down information silos by requiring equipment to be equipped with digital meters during the initial factory planning phase, planning from the ground up so that subsequent data analysis has raw materials; for old factories, since equipment did not previously report energy data, we use an IoT platform for energy data collection." It is estimated that this project will bring benefits of over 22.75 million RMB annually.

Industrial geeks must have the ability to solve problems simply and efficiently. Chen Qin recently worked on a project: efficiently classifying and analyzing frequent equipment alarms. The factory has over 2000 devices, each with up to tens of thousands of alarm types. In the past, pure manual analysis was extremely inefficient; on the other hand, analyzing only the top 10 makes it difficult to identify specific causes. "We first mapped the alarm codes and reason codes reported by the machines. When an alarm occurs, the database directly converts it into a reason code based on the mapping table for analysis, making it clear whether it's a motor abnormality, sensor issue, etc."

Industrial Geek is a passion and persistence for technology

Wei Louer, a big data assistant engineer at Gotion Smart stationed at Shenzhen Huaxing, is a post-95s graduate who joined Gotion Smart right after university, majoring in image analysis. Driven by a love for this work, she has developed many practical systems.

"When I visited the factory once, I saw many employees doing light-on quality inspection: after sending test signals to the panel, they observe the test images on the screen and manually judge the panel's quality. Light-on inspection has high labor costs; how to reduce costs and improve efficiency led to this Golden Idea Contest proposal." Taking T2 factory's CELL secondary light-on as an example, there are about 20 light-on machines, with day and night shifts totaling 20 people, plus module light-on, the manpower consumption is可想而知. Wei Louer believes that借鉴 the ADC project (AI automatic defect classification system)思路 can solve this problem by using AI machine vision technology to achieve smart light-on, saving manpower for light-on inspection. The daily judgment count for 20 people will increase from 10,800 pieces per day to 21,600 pieces with the smart light-on system.

Wei Louer is currently participating in a new machine vision project at TCL Hong Kong Research Institute, focusing on algorithm development. "Algorithm development is quite challenging and involves a wide range, but it's very interesting and fun."

Industrial Geek is a spirit of research and dedication

Huang Xi, a senior network architecture management engineer at Gotion Smart stationed at Huizhou Huaxing, often strives to do everything to the extreme in daily细微 work.

"Every time the industry builds a factory, a computer room is set up, and each room reserves cabinets for future expansion, so we found many idle cabinets. This Golden Idea Contest proposal involves integrating and centrally managing computer room resources under the industry to effectively utilize idle resources."

Huang Xi often makes micro-innovations in daily work. For example, in the Huizhou module factory computer room project, Huang Xi equipped power distribution cabinets with smart meters, cabinets with temperature sensors, and a series of sensors for temperature, smoke, infrared, combustible gas, and PM2.5 to collect environmental information from the computer room. If abnormalities occur, causes can be quickly identified, achieving精细 monitoring of the computer room, with real-time monitoring via mobile APP.

Gotion Smart's 'Industrial Geek' culture,

originates from the company's consistent product philosophy of simplicity, efficiency, and DIY;

is an identity describing technical personnel in the industrial field with a passion for learning, a spirit of research, and strong hands-on abilities;

is also an attitude and spirit of simple innovation, in-depth exploration, and hands-on action towards things of interest.