New Perspective | 5 Misconceptions in Factory Equipment Management Under New Conditions

Problem and Challenge: With the improvement of equipment automation and digitalization, factories urgently need to build management capabilities for new types of equipment

Under the wave of global smart manufacturing, China's manufacturing industry is actively upgrading and transforming. The levels of automation, digitalization, and networking have greatly improved. Production equipment is becoming increasingly integrated and intelligent, with enhanced data visibility and simpler operations. However, this also brings increased difficulty in equipment maintenance and repair, higher maintenance costs, and a more prominent role for equipment maintenance.

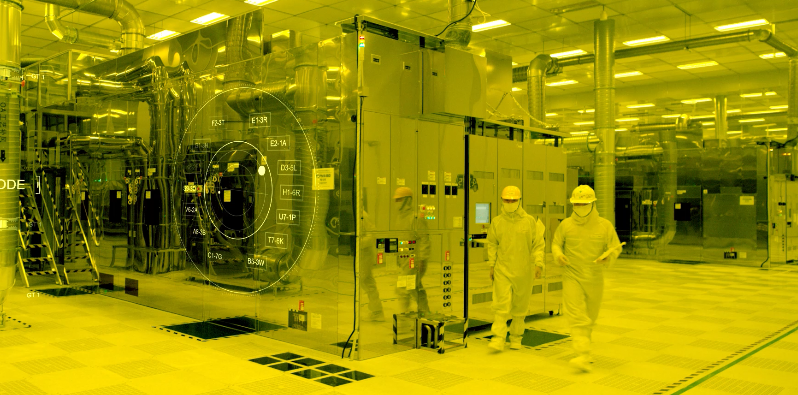

What will the future factory look like? At TCL CSOT, a representative enterprise in high-end manufacturing, the author observed that there are only two types of people on the production floor: equipment maintenance personnel and engineering technicians. Processes are embedded in software systems, and everyone monitors and operates equipment and process parameters on computers. Operators use Dongzhi Equipment Health Management Software for mobile inspections, remote collaborative operations, vibration monitoring analysis, and predictive maintenance of equipment. However, in many other enterprises, we see that companies invest heavily in very advanced equipment, but equipment management, maintenance, and personnel knowledge structures remain at a traditional level: data collection relies on pen and paper, processing relies on people, and analysis relies on guesswork (experience). It can be said that they have purchased Industry 4.0 equipment but continue with Industry 1.0 management.

Figure: On-site equipment and process inspection at CSOT

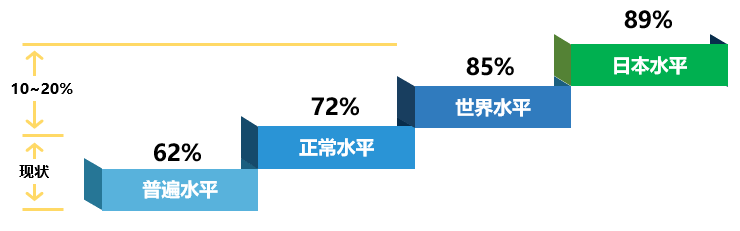

In terms of the efficiency output of equipment assets, we see that there is significant room for improvement in the overall equipment efficiency (OEE) of China's manufacturing industry. According to statistics, the OEE of most discrete manufacturing industries in China is between 60% and 70%, which is at least 10% lower than that of developed countries. At the same time, many factories do not pay enough attention to the fine management of equipment maintenance, resulting in hidden losses such as abnormal downtime and spare parts waste, which represent significant wastage. In the current context of the pandemic impact and increasing uncertainty in the global situation, these areas for efficiency improvement can provide valuable opportunities for corporate survival and enhanced competitiveness.

Figure: Current OEE assessment in discrete manufacturing

How to build management capabilities for new types of equipment is a problem and challenge currently faced by the manufacturing industry. In this process, we have summarized five common misconceptions to help companies avoid detours.

First, prioritizing hardware over software.

Most companies, when building new factories or purchasing new equipment, focus only on the acceptance and handover of hardware, neglecting software maintenance, calibration standards, and failing to clearly specify requirements for equipment data collection interfaces and data ownership. According to the latest statistics from the Ministry of Industry and Information Technology, the average digitalization rate of production equipment in Chinese enterprises is 47%, the numerical control rate of key processes is 51%, and the networking rate of key equipment is 41%. Embedded software, human-machine interfaces, data monitoring models, and management platforms are all important components of new equipment and should fall within the scope of new equipment management. Based on the author's experience with industrial internet projects, equipment data collection remains one of the most costly components of digital advancement on the production floor due to the multitude of industrial protocols, lack of support or openness from original equipment manufacturers, and unclear data ownership.

Therefore, factories should consider these requirements during the equipment procurement phase and include them in commercial terms to prepare for detailed data collection and analysis optimization of equipment processes in the future.

Second, prioritizing production: no repair if not broken, no management if not stopped.

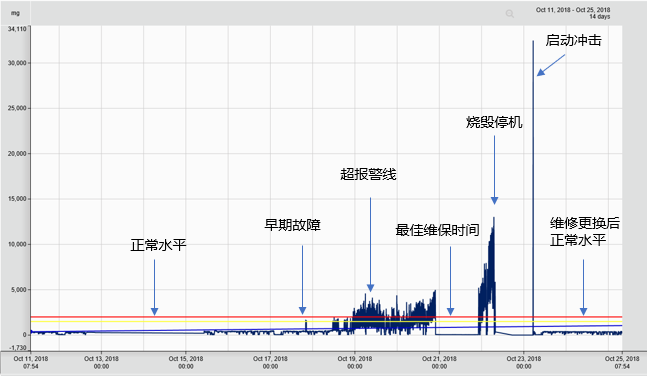

In most factories, especially in discrete manufacturing, production is the top priority, and equipment is merely a support department. As long as the equipment is still running, production will not stop. This leads to severe underinvestment in time and funds for equipment maintenance improvements, trapping the equipment department in a vicious cycle of firefighting and passive response. The root cause is the failure to view the losses from equipment downtime from an end-to-end factory perspective. Intervening with maintenance at the early signs of equipment issues results in far less loss and cost than waiting until a breakdown occurs. For example, as shown in the figure below, vibration analysis detected an early warning threshold being triggered on October 18, but due to production scheduling issues, no maintenance was performed. On October 22, the machine's main control system triggered a fault, necessitating a 10-hour shutdown for bearing repair and replacement. After repairs, vibration returned to normal levels, but significant losses had already occurred.

Figure: Vibration analysis can monitor most mechanical faults

Looking at the four main stages of equipment management evolution—from 1.0 corrective maintenance (CM), to 2.0 preventive maintenance (PM), 3.0 reliability-centered maintenance (RCM), and 4.0 predictive maintenance (PHM)—the essence is an evolution centered on equipment health management (EHM), moving from "treating existing problems" to "preventing problems." Through EHM, equipment health is no longer simply categorized as normal or abnormal. We can use new technologies and tools to analyze accumulated data and assess the sub-health state of equipment. Intervening at this stage can significantly reduce equipment maintenance costs. For example, Dongzhi Equipment Management Software equips engineers with smart inspection devices equipped with vibration sensors, akin to giving doctors "smart stethoscopes." By monitoring vibration spectra for a few seconds and combining them with built-in spectrum analysis models, they can accurately and quickly determine equipment health status and fault symptoms, playing a major role in auxiliary fault diagnosis. This shifts the role of equipment personnel from repairing breakdowns to focusing more on professional maintenance to ensure equipment health, entering a virtuous cycle.

Third, treating equipment issues as solely the equipment department's responsibility.

Although TPM (Total Productive Maintenance) has been promoted for many years, many managers still believe, both in mindset and action, that equipment problems are solely the responsibility of the equipment department. This leads to production departments not caring about equipment failures and not prioritizing equipment maintenance that affects output and quality. Equipment maintenance engineers often have low status and low pay, self-deprecating as watchdogs and scapegoats: during holidays, when others rest, they cannot leave because it is an ideal time for equipment repairs; whenever problems occur, whether equipment downtime, production stoppages, or quality, safety, or environmental incidents, they are all related to equipment, and equipment managers are almost always on the defensive, constantly blamed. Senior management often thinks of the equipment maintenance department only during unpleasant times. As a result, the entire equipment department becomes the last place talented people want to work. This vicious cycle requires production managers to lead by example in establishing correct equipment management concepts and building a company-wide autonomous maintenance system with production as the main body. Only when production department managers prioritize this can all production equipment operators change their indifferent attitude toward equipment and effectively perform equipment maintenance. This cannot be achieved by the equipment department alone.

Companies can introduce advanced equipment health management software to build a company-wide autonomous maintenance system, enabling operators' daily autonomous inspections and maintenance, the equipment department's professional inspections, equipment fault reporting via QR codes, QR code-based maintenance, autonomous task assignment for maintenance work orders, user evaluation of repair effectiveness, and performance competition. These functions and mechanisms help factories achieve self-sustaining TPM.

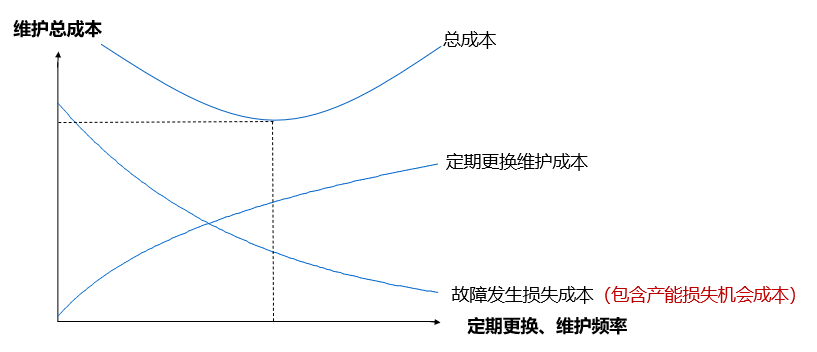

Fourth, treating equipment maintenance as a cost center while ignoring hidden losses beneath the surface.

Many managers believe that zero equipment failures are unattainable. When companies face difficulties and need to cut costs, they often target equipment maintenance budgets, even proposing goals to reduce maintenance budgets by a certain percentage annually. From a traditional financial perspective, funds spent on maintenance are generally defined as costs and expenses. As early as 30 years ago, at the European Federation of National Maintenance Societies international conference in Wiesbaden, Germany, the theme was "Maintenance—An Investment in the Future." As an investment, it requires clear input and output. The input for maintenance includes labor costs, various protection fees, spare parts costs, and equipment management-related systems. What is the output? The losses caused by insufficient equipment maintenance and poor equipment management, such as equipment downtime, precision or quality defects. Misjudging the value of these losses can easily stifle improvement investments in equipment maintenance technology and management systems.

The author once served a large factory where the equipment department wanted to implement an EHM project to achieve equipment data collection and monitoring, along with mobile inspections for equipment reporting and maintenance processes, forming a fault tree record for equipment. When calculating the input-output, they were repeatedly challenged by finance and could not pass. They understood the value of reducing equipment downtime by one hour as merely the labor cost of employees involved during that hour. Calculated this way, the value output was too low, and many equipment improvement projects could not be implemented. Moreover, such a project value calculation standard directly suppressed the factory's enthusiasm for lean innovation. The loss from one hour of equipment downtime should be measured end-to-end from the factory's perspective. This includes the opportunity cost of lost capacity, i.e., the loss of product output value for one hour, which is the real loss for the factory. Calculated this way, many small improvement projects for reducing downtime, waste, and on-site lean initiatives can be reasonably carried out, stimulating innovation among frontline employees and bringing tangible benefits to the factory.

Another practical issue is that spare part replacements are largely in the hands of maintenance workers, with many "human-controlled" factors. Maintenance personnel mostly rely on experience to judge the degree of spare part damage. For components suspected of faults, they often replace them with new ones to reduce responsibility or lower work difficulty, even if the parts are still usable, leading to hidden waste from over-maintenance. For example, at TCL CSOT, since most parts are imported, annual spare parts costs amount to nearly one billion yuan. By implementing精细化 spare parts lifecycle management through Dongzhi Equipment Health Management Software, they save tens of millions of yuan annually.

From these perspectives, equipment maintenance has shifted from emphasizing service to production and pursuing high equipment availability rates to focusing on the company's economic benefits. This requires equipment management to emphasize the management and control of maintenance costs, finding the balance point where the least maintenance cost achieves the highest equipment availability. If senior managers can view maintenance and equipment management from an "investment" perspective, it will be a valuable management innovation and mindset change.

Figure: The essence of equipment management is finding the optimal maintenance balance

Fifth, relying on "predictive maintenance" to solve problems while neglecting foundational digital construction and data accumulation.

"Predictive maintenance" has always been a hot topic in the industrial internet. In recent years, many companies claim to have achieved predictive maintenance through IoT and AI, raising expectations. Enterprises hope to hand over their equipment management challenges to "predictive maintenance." However, based on the author's observations, most are still conceptual and experimental projects, lacking explainability, verifiability, and replicability. To this day, the hype around predictive maintenance solutions solely based on big data and AI is diminishing.

The implementation of predictive maintenance solutions is more difficult than expected because attempting to extract explainable industrial mechanism logic solely from data is far more challenging than imagined. There are two main reasons: first, many companies lack accumulated foundational data. For example, basic equipment inspections, maintenance records, and fault analysis records are still scattered across various papers and Excel files. Equipment lacks digital records, basic maintenance data, spare part replacement records, fault and repair data, and most importantly, structured accumulation of equipment fault characteristic data, making model training and validation impossible. Second, many vendors rely solely on data analysis paths while ignoring the integration of equipment engineers' existing professional knowledge and experience. Relying solely on mathematics and AI algorithms容易 leads to statistical traps and makes it difficult to derive ideal, explainable predictive models.

Overall, equipment is to a factory what a gun is to a soldier. Many equipment maintenance and repair technical systems indeed evolved from military weapon maintenance systems. Building new equipment management capabilities requires factory managers to recognize the foundational role of equipment in core competitiveness and actively promote changes in equipment management and operational methods toward digitalization and intelligence. According to Gartner predictions, by 2022, over 60% of equipment will achieve data-based intelligent operation and maintenance. Equipment intelligent management and operation capabilities will be an important indicator of a factory's core competitiveness. Recently, relevant national departments are drafting and formulating national standards for equipment management and capability maturity assessment frameworks, which will guide and promote enterprises in strengthening new equipment management capabilities.

Author: Fred, GTRONTEC Dongzhi Equipment Management Solution Expert, 10 years of experience in manufacturing IT, 10 years of experience in smart manufacturing and digitalization, rich project experience in on-site lean management, standardized factories, supply chain process innovation, and digital factories, participated in the drafting of industrial internet system standards and GB equipment management maturity assessment system standards.