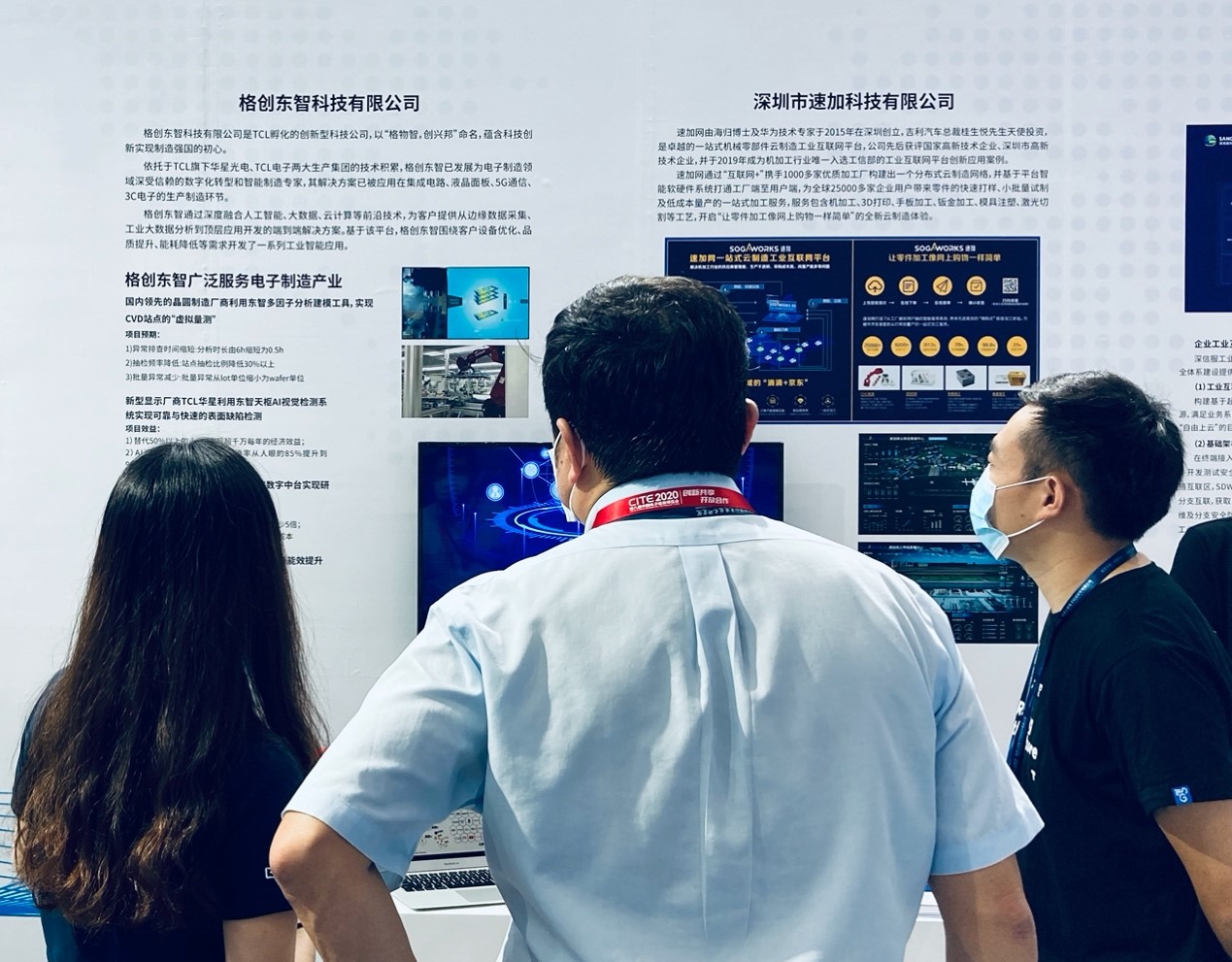

GTRONTEC Invited to China Information Technology Expo 'Information Communication Industry Cluster Exhibition'

From August 14-16, the 8th China Information Technology Expo was grandly held at the Shenzhen Convention and Exhibition Center. GTRONTEC was invited to participate in the '2020 New Generation Information Communication Industry Cluster Exhibition' co-organized by the Shenzhen Municipal Bureau of Industry and Information Technology and the China Electronics Expo Organizing Committee.

The '2020 New Generation Information Communication Industry Cluster Exhibition' focused on showcasing the achievements of Shenzhen's new generation information communication industry cluster over the past year, highlighting 5G, integrated circuits, new displays, and related industries in the segmented market. It displayed relevant industry chains, platforms, and applications, serving as a concentrated demonstration of Shenzhen's new generation information communication technology across various scenarios.

GTRONTEC, incubated by TCL's two major production groups, TCL CSOT and TCL Electronics, has set application benchmarks in high-quality management and low-code services across semiconductor process industries and 3C electronic discrete industries. GTRONTEC launched the industry's first 'production-site-oriented' Dongzhi Industrial Application Intelligent Platform, providing scenario-based solutions for customer needs such as equipment optimization, quality improvement, and energy consumption reduction. To date, it has served electronic manufacturing enterprises in wafer manufacturing, new display panels, 5G communication modules, and 3C electronics.

Wafer Manufacturing Industry

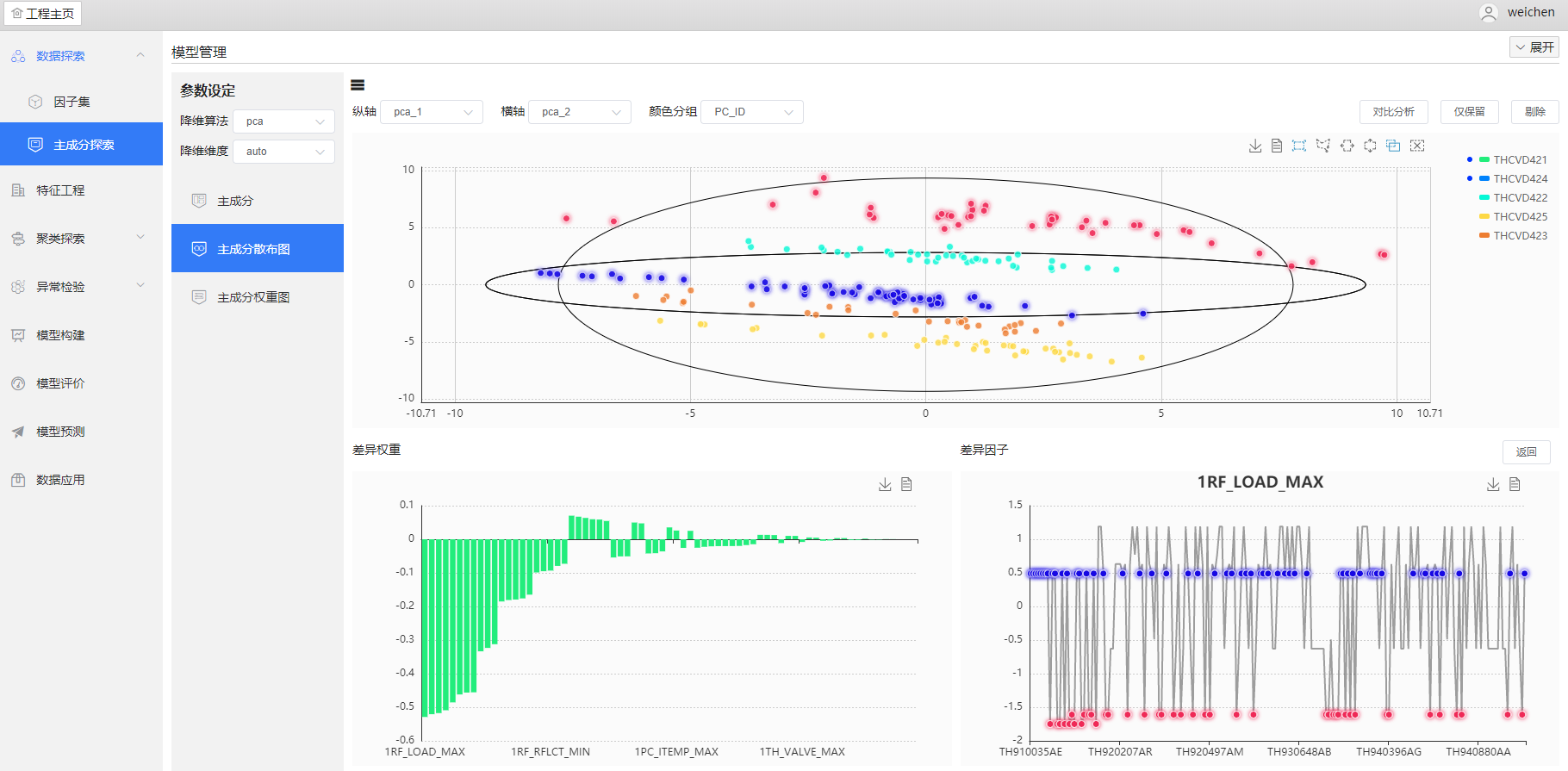

Using Dongzhi MFA Multi-Factor Analysis Modeling Tool to Achieve 'Virtual Measurement' at CVD Stations

The Dongzhi MFA Multi-Factor Analysis Modeling Tool is a factor mining and modeling tool for industrial big data analysis, helping production engineers efficiently model and deeply explore data value. Using the Dongzhi Multi-Factor Analysis Modeling Tool, digital solutions such as quality analysis, quality prediction, and equipment predictive maintenance can be achieved.

A leading domestic wafer manufacturer used the Dongzhi MFA Multi-Factor Analysis Modeling Tool to achieve virtual measurement at CVD (Chemical Vapor Deposition) stations, reducing analysis time for anomaly troubleshooting from 6h to 0.5h; sampling inspection ratio decreased by over 30%; and batch anomaly units were reduced from lot to wafer level.

New Display Industry

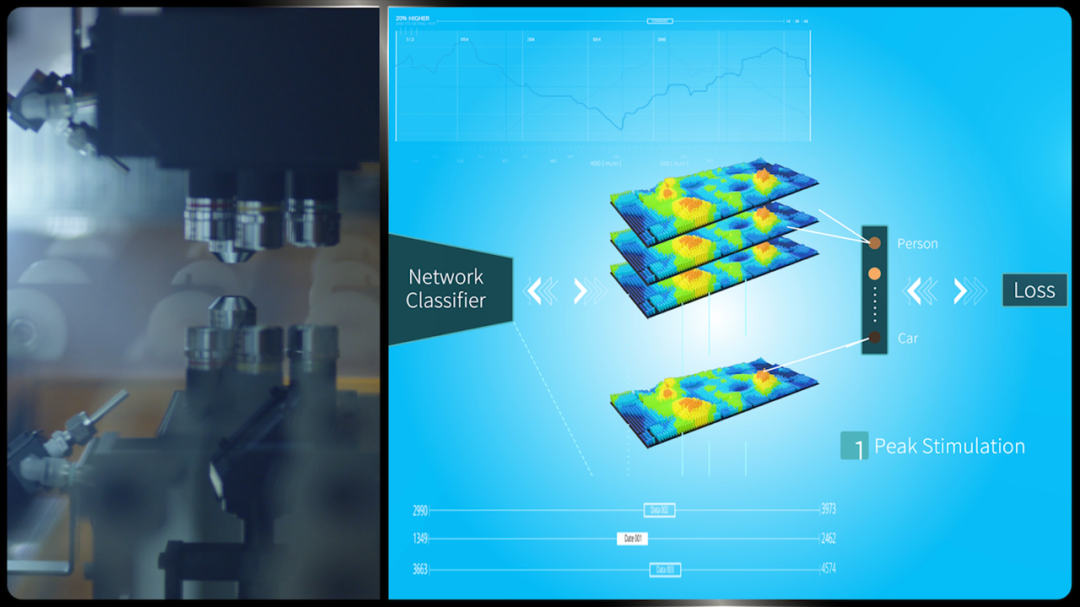

TCL CSOT Uses Dongzhi Tianshu AI Visual Inspection System for Reliable and Rapid Surface Defect Detection

The Dongzhi Tianshu AI Visual Inspection System is a digital solution based on AI technology to address the shortcomings of traditional AOI in complex scenario detection. The system enables autonomous learning of detection methods and self-optimization of detection models, completely replacing manual re-judgment in traditional machine vision, providing industry with tireless eyes and a brain.

Domestic new display manufacturer TCL CSOT adopted the Dongzhi Tianshu AI Visual Inspection System for surface defect detection of display panels, replacing 50% of human labor and achieving annual economic benefits exceeding tens of millions; AI recognition speed increased by 5-10 times, and detection accuracy improved from 85% with human eyes to over 90%.

5G Communication Manufacturing Industry

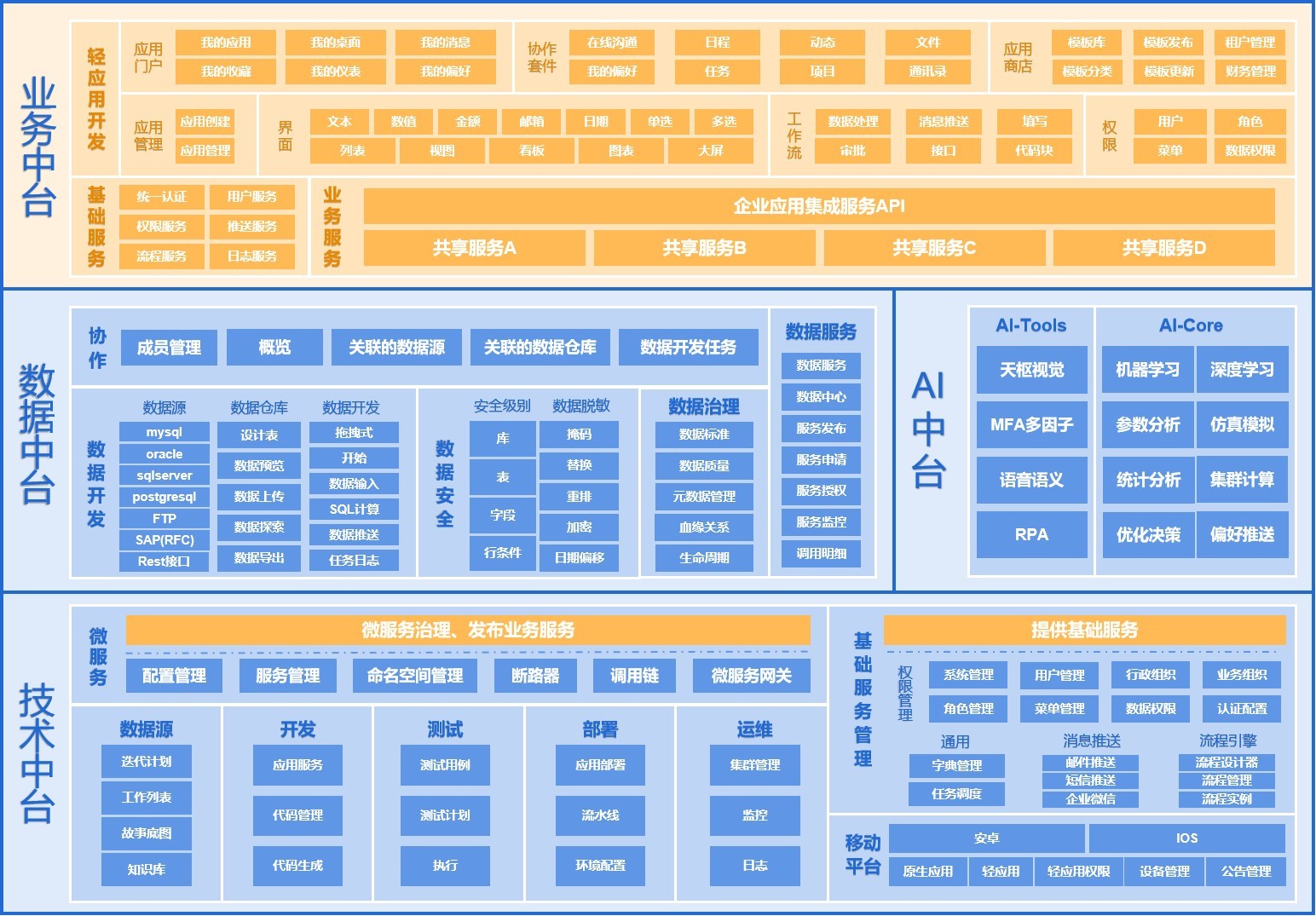

Using Dongzhi Digital Middle Platform to Achieve Agile R&D

The Dongzhi Digital Middle Platform is an enterprise-level capability reuse platform for data assets, where production logic, business processes, and knowledge experience are digitized and intelligentized, serving as the support and driving force for enterprise business and processes. Integrated with the IoT platform, the Dongzhi Digital Middle Platform allows direct data selection and modeling within the IoT platform.

A well-known domestic 5G communication manufacturer adopted the Dongzhi Digital Middle Platform, achieving at least a 5x speed increase in building new applications compared to traditional architectures; by gradually replacing traditional applications with the Dongzhi Digital Middle Platform, legacy system maintenance costs were reduced by 50%.

3C Electronics Industry

TCL Electronics Uses Dongzhi Equipment Health Management to Improve Equipment Efficiency

The Dongzhi Equipment Health Management Tool includes six functional modules: equipment basic data, planned maintenance, parameterized maintenance, spare parts management, remote maintenance, and predictive maintenance. By helping factories implement equipment management systems and sort out fault mechanism models, it builds a comprehensive equipment health management system centered on equipment health operation.

TCL Electronics used the Dongzhi Equipment Health Management Tool to significantly improve equipment efficiency. Within 10 months of tool deployment, abnormal downtime decreased by about 50%; single maintenance operation evaluation time reduced by about 20%; and spare parts costs decreased by 20%.

The service cases showcased by GTRONTEC in wafer manufacturing, new display panels, 3C electronics, and 5G communication modules demonstrate that GTRONTEC's products have been successfully applied in various manufacturing scenarios, fully empowering electronic information manufacturing enterprises with intelligent and digital upgrades.

Join hands with GTRONTEC to make industry smarter!