GTRONTEC: Deep Thinking After the Championship

Recently, at the 2020 China (Tianjin) Industrial APP Innovation Application Competition award ceremony, GTRONTEC won the championship trophy in the special competition for aiding epidemic prevention and control and resuming work and production with its "Rapid Development and Application Solution for Industrial Robot Remote Real-Time Operation and Maintenance APP".

◎ GTRONTEC Wins the Championship Trophy in the Special Competition for Aiding Epidemic Prevention and Control and Resuming Work and Production

Upon receiving this honor, GTRONTEC CEO He Jun remarked: "This is not only the result of GTRONTEC's relentless efforts over the past two years but also the recognition from industry experts and partners. The path of industrial APP development is long and arduous, and we will only take this as a new starting point for another expedition. In the future, GTRONTEC will continue to deepen cooperation with industry partners, focus on the most urgent transformation needs of enterprises, build industrial APP solutions for different industry scenarios, help enterprises overcome the 'last mile' of industrial internet application, and contribute to enterprise digital transformation and intelligent upgrade."

Two Years of Efforts Now Yield Results

In 2018, GTRONTEC was incubated by TCL, focusing on the research and development of industrial internet platforms. When mentioning GTRONTEC, it is often compared to industrial internet platforms like Rootcloud, COSMOPlat by Haier, and Midea Cloud. These industrial internet platforms源自大型制造企业都拥有深厚的工业基础和行业背景,对行业痛点和企业需求“把脉”更为全面精准。

这些公司在成立之初,多以集团变革需求为业务核心,通过全面支撑集团的数字化和智能化转型升级,不断积累并深化行业数字化转型服务的能力和经验,在此基础上构建面向行业的智能制造及工业互联网解决方案,最终形成工业数字化服务的外溢效应。但深入了解会发现,各家源自制造业的工业互联网平台厂商在发展路径上有着明显区别。格创东智在人才资源配备上更重视外部引进和集团调任的“人才融合”策略。

何军认为,制造业行业众多且工艺流程复杂,不同行业和规模的企业在运营模式、生产工艺和人才水平上千差万别,格创东智要做的是把企业数字化应用现状、需求和能力统一抽象出来,提供标准的具有较高共性的功能模块,让企业能通过调用模块快速开发APP,满足行业对敏捷制造的转型需求。要达成这一目标,除了需要制造行业专家提供丰富的行业实践经验外,具有资深数字化研发背景和经验的IT专业人才更不可或缺。

Currently, GTRONTEC has nearly 900 employees, including IT professionals introduced from high-tech companies like Cisco, Huawei, IBM, Alibaba, Microsoft, as well as industrial experts from Siemens, GE, Midea, etc. Over the past two years, the IT and OT talent integration strategy has greatly promoted the development of GTRONTEC's technical platform, not only launching the Dongzhi Industrial Application Intelligent Platform but also developing multiple industrial intelligent applications such as quality analysis, equipment management, visual inspection, multi-factor analysis, and virtual measurement based on this platform, greatly meeting enterprise needs for improving quality and reducing energy consumption, and gaining attention in the high-end manufacturing field.

In April this year, GTRONTEC's self-developed "MFA Multi-Factor Analysis APP Solution" was selected by the Ministry of Industry and Information Technology as an excellent solution for industrial internet APP in 2019. In October, at the 2020 China (Tianjin) Industrial APP Innovation Application Competition hosted by the Ministry of Industry and Information Technology and the Tianjin Municipal People's Government, GTRONTEC's self-developed "Rapid Development and Application Solution for Industrial Robot Remote Real-Time Operation and Maintenance APP" won the championship in the special competition for aiding epidemic prevention and control and resuming work and production. In industrial internet platform selection activities held by major industry media, the Dongzhi Industrial Application Intelligent Platform has attracted user attention due to numerous industry landing cases and steadily ranked in the top twenty.

Currently, GTRONTEC has cases in industries such as wafer manufacturing, chip packaging and testing, liquid crystal display, 3C electronics, 5G communication, and new energy, with obvious advantages in the semiconductor and pan-semiconductor industries. According to statistics, from mid-2019 to now, GTRONTEC has implemented over 300 industrial internet projects with a large number of landing cases.

Accumulated Strength Makes Industry Smarter

Over the past two years, GTRONTEC has timely洞察客户需求 when market conditions change, thus launching more targeted industrial APP solutions to help enterprises solve the most urgent application needs.

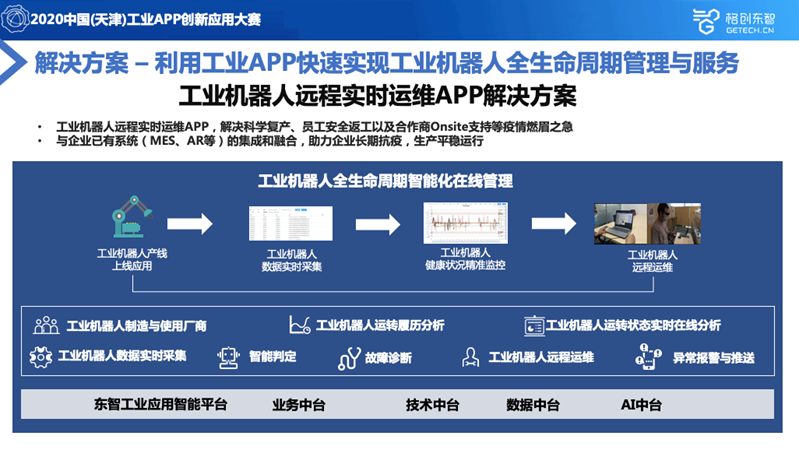

△ Rapid Development and Application Solution for Industrial Robot Remote Real-Time Operation and Maintenance APP

For example, the "Rapid Development and Application Solution for Industrial Robot Remote Real-Time Operation and Maintenance APP" that won the championship at the 2020 China (Tianjin) Industrial APP Innovation Application Competition came from deep insights into customer needs during the pandemic.

In early 2020, the outbreak of the COVID-19 pandemic caused many enterprises to face numerous problems in production and delivery. Especially for industrial enterprises高度依赖于工业机器人生产, since a large number of industrial robots require timely maintenance, the pandemic prevented equipment service providers from reaching the site, and enterprises could not open production network permissions to service providers for remote maintenance, directly putting production line industrial robots in a "naked running" state, posing great risks to production.

Facing this dilemma, GTRONTEC's R&D team quickly developed the "Industrial Robot Remote Real-Time Operation and Maintenance APP" system to solve the sudden运维难题 of industrial robots, achieving intelligent online operation and maintenance throughout the lifecycle of industrial robots. Based on the Dongzhi Industrial Application Intelligent Platform, the APP was launched in only 40% of the industry average development cycle through low-code, drag-and-drop graphical development. Since services are provided through the APP, there is no need to consider complex underlying access environments like industrial networks, greatly ensuring data security.

Besides problems on the production site, the pandemic also greatly impacted the business management and delivery of manufacturing enterprises. For example, at a globally leading large equipment manufacturing enterprise, the pandemic prevented customers from arriving on-site to understand various states of the equipment, making equipment delivery and acceptance difficult. How to ensure delivery capability became a huge test for equipment manufacturing enterprises during the pandemic.

To address this, GTRONTEC built a remote delivery system based on 5G+AR technology for this enterprise. Relying on the high bandwidth, low latency, and wide connectivity provided by 5G networks, it constructed remote AR acceptance scenarios, allowing customers to immersively experience various indicators and performance of the equipment, greatly simplifying the customer delivery and acceptance process, and achieving customer satisfaction. GTRONTEC is taking this industry practice as an opportunity to expand 5G+AR scenario-based services to other industries.

If the pandemic is a surprise exam, then in this big test, GTRONTEC passed smoothly with keen insight and rapid application development capabilities.

GTRONTEC is helping enterprises solve problems faced in the smart manufacturing transformation process from a full industry chain perspective.

At Wuhan Steel维尔卡钢绳制品公司, to打通产业链上下游,实现订单、生产、采购、仓储、交付等过程的一体化运作,在内部实现企业横向端到端的业务集成需求,在外部实现纵向端到端的智能管理决策需求,公司以东智工业应用智能平台集成ERP、MES等业务系统,以及IOT设备管理系统功能模块,实现业务的全集成和数据的全流动,不仅提高了生产效率,也在行业建立产业竞争优势。

Steady and Far-reaching Future Deep Thinking

At the 2020 China (Tianjin) Industrial APP Innovation Application Competition award ceremony, GTRONTEC CEO He Jun used one sentence to describe the prospects of current industrial APP ecological development. He said, "Chinese industrial enterprises need platforms and tools that quickly support APP development."

Recognizing this issue, at the award ceremony, He Jun announced that GTRONTEC will join the "Million Industrial APP Ecological Cultivation Plan", opening the Dongzhi Industrial Application Intelligent Platform functional components and business models to broader third-party developers, platform partners, and enterprise customers, promoting industrial APP ecological construction through open source, and building an open, shared, and collaborative social innovation ecological environment.

To cultivate the industrial APP ecology and promote industrial internet industry construction, over the past two years, GTRONTEC has made many efforts and attempts, including building a Poros digital middle platform for China's largest 5G communication equipment manufacturer, using microservices technology to help customers achieve agile development of business systems, joining the China Industrial Internet Industry Alliance platform group, etc., and these efforts are achieving significant results.

For the next step of development, He Jun revealed his thoughts. In the future, he will mainly plan and promote GTRONTEC's development from three directions:

First, taking the opportunity of joining the Million Industrial APP Ecological Cultivation Plan, provide open Dongzhi Industrial Application Intelligent Platform functional components and business models to third-party developers, accelerating industrial APP ecological construction. At the same time, continue to increase independent industrial APP development and innovation efforts, create more and better industrial APP products for enterprises of different industries and scales, and continuously deepen the industry transformation process.

Second, further deepen cooperation with industry leading enterprises, jointly explore and build面向行业工业互联网应用场景,推动行业场景落地,赋能行业数字化转型和智能化升级,以标杆力量引领更广大的企业加速转型。

北京康吉森自动化设备技术有限责任公司是一家集研发、生产、销售、工程服务和售后服务于一体的自动化控制系统公司,主要为石油、化工、铁路、冶炼等行业客户提供技术产品和解决方案。在充分评估后,康吉森与格创东智达成战略合作:共同打造面向石化行业的工业互联网服务平台,提供EHM设备健康管理、Web门户以及移动APP中心及微信生态体系等多类型平台应用。该合作为石化行业的工业互联网生态体系建设迈出重要一步。

Third,持续深化”对内赋能+对外输出”战略,通过不断积累行业服务经验形成对外的服务输出效应,特别在半导体行业,通过为TCL华星提供数字化转型服务支撑,格创东智积累了丰富成熟的半导体行业转型服务经验,目前正在向半导体上下游产业进行拓展。

In the process of digital transformation and intelligent upgrade, industrial internet has become an important driving force. Facing the increasingly蓬勃的智能应用场景构建需求,唯有不断创新,以企业需求为抓手,以应用效果为导向,实实在在帮助企业解决问题,才能在工业互联网产业发展浪潮中落沉为金!

About Us | GTRONTEC is a leading industrial internet company Product Concept | Simple and Efficient DIY, Empowering the New Generation of Industrial Geeks Product Positioning | Focus on the production site, dedicated to data value realization