How can large, medium, and small factories undergo intelligent transformation?

"Industrial Internet not only addresses production issues but also human-related challenges, such as supply chain management. The major technological challenge lies in achieving flexible manufacturing through industrial Internet technology."

"China is not yet a manufacturing powerhouse; many traditional manufacturing enterprises still rely on labor-intensive methods, facing risks like high energy consumption and equipment damage."

Intelligent Manufacturing, "Chip" Towards the Future—Intel's Intelligent Manufacturing Roundtable was held online on September 23. Yang Xiaoliang, Chief Architect of GTRONTEC, was invited to share practical insights and future perspectives.

"Thank you to Intel for providing this opportunity to gather and discuss the future of intelligent manufacturing. My presentation, 'Intelligent Manufacturing, Chip Towards the Future,' highlights GTRONTEC's efforts in applying industrial Internet technology to chip manufacturing and semiconductors."

GTRONTEC's Dongzhi Industrial Application Intelligent Platform is built on a foundation of public, private, or hybrid cloud infrastructure. From the bottom up, the platform connects with traditional factory equipment, such as SCADA (Supervisory Control and Data Acquisition) systems, and software like MES (Manufacturing Execution System), ERP (Enterprise Resource Planning), and PLM (Product Lifecycle Management).

Data collected via edge devices is sent to the platform to uncover deeper insights. Industry experience and knowledge are used to build industrial algorithm and model libraries, packaged as microservices. Additionally, aPaaS leverages the platform to develop industrial apps.

GTRONTEC currently offers numerous end-to-end databases, such as the Equipment Health Management System (EHM) for digital factories and the machine vision system Dongzhi Tianshu. On the factory floor, machine vision products can automatically detect defects, while the Multi-Factor Analysis (MFA) tool delves into data to model relationships between results and parameters.

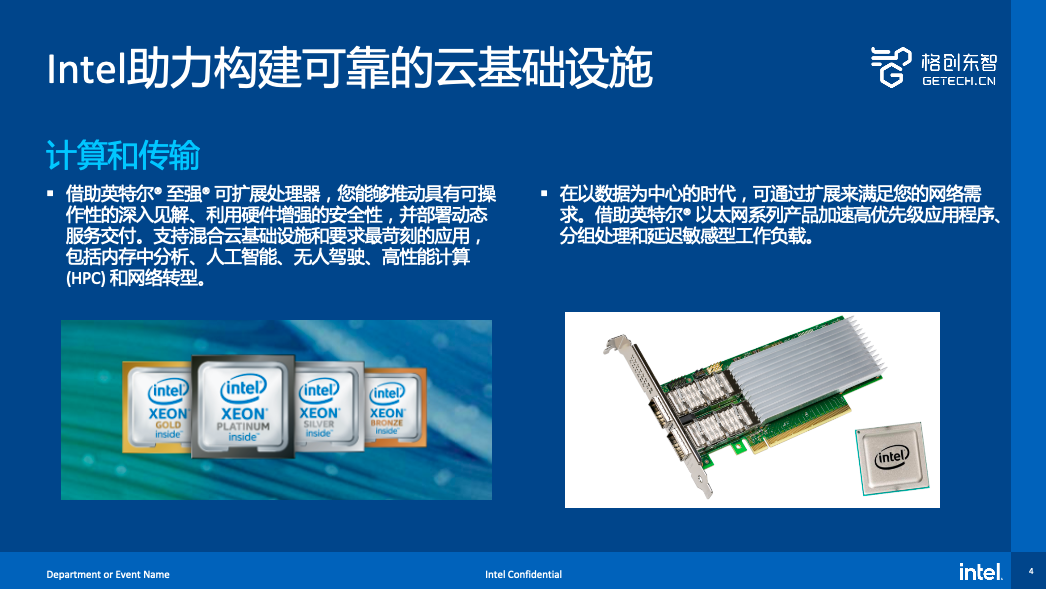

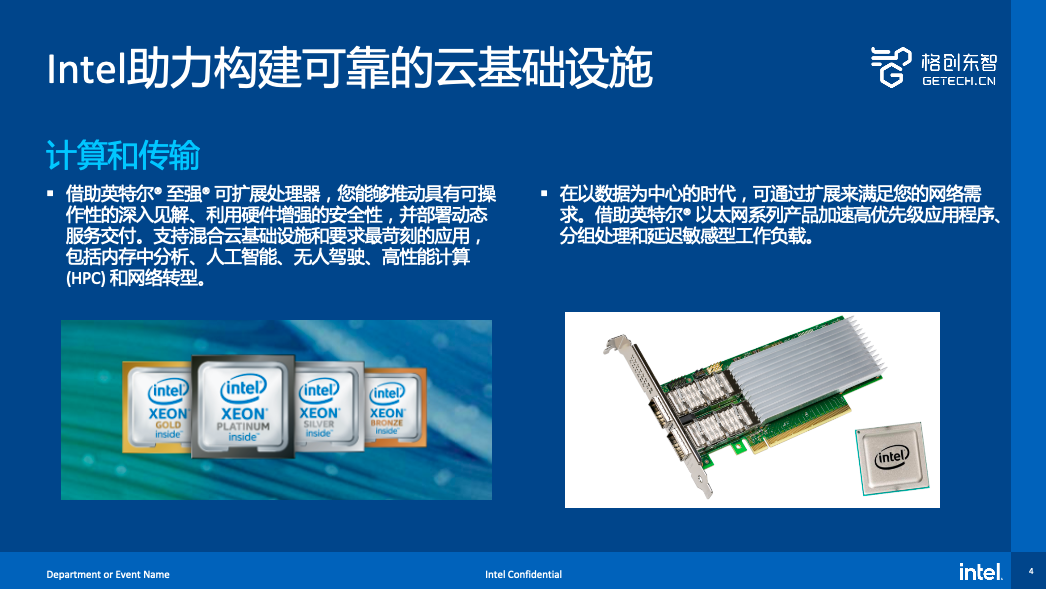

These technologies rely on three foundations: computing, transmission, and storage. Computing: Intel Xeon processors provide stable computational power. Transmission: Intel Ethernet technology meets network demands through scalability, accelerating high-priority applications and ensuring rapid data transfer between cloud infrastructures.

Storage: Intel's Optane technology includes memory and SSDs, both critical components of cloud infrastructure.

As a benchmark in the semiconductor industry, how does GTRONTEC contribute back to this sector?

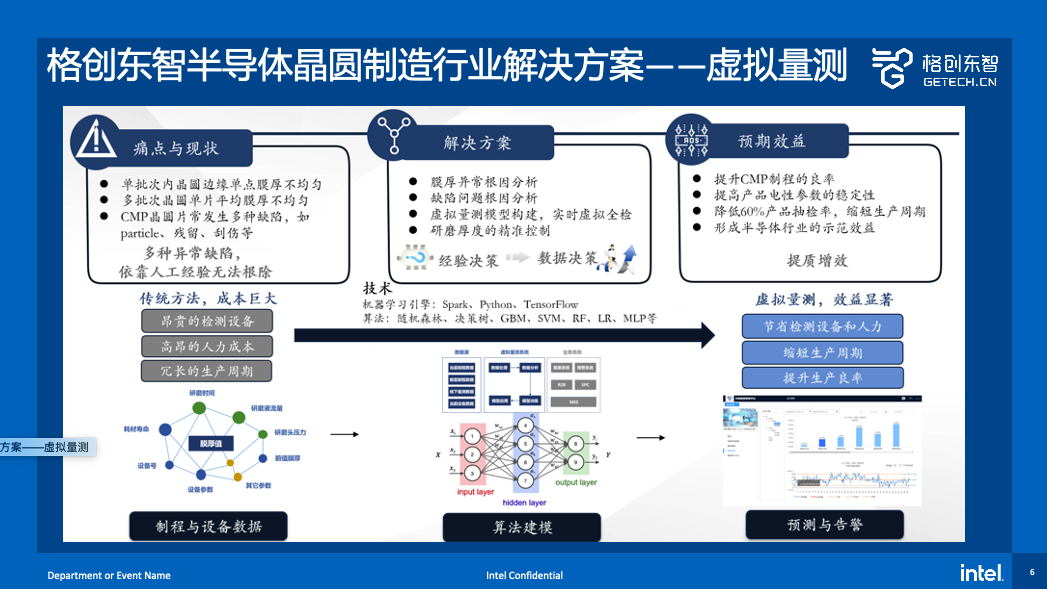

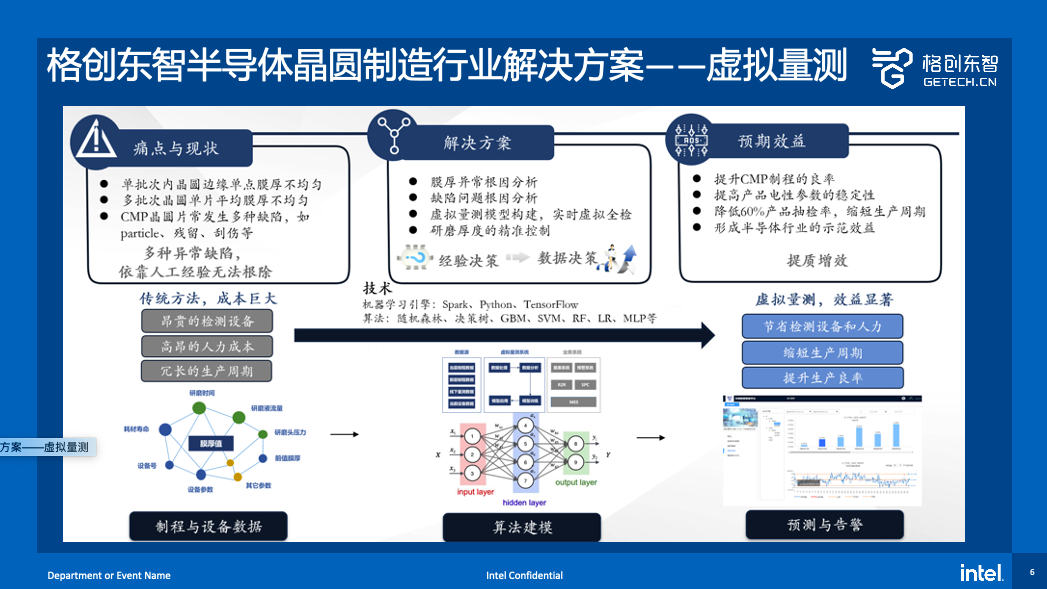

One of GTRONTEC's flagship products is virtual metering. In actual production, many abnormal defects cannot be resolved through manual experience alone, as a single defect may relate to dozens of parameters. Big data analytics can uncover these relationships, leading to benefits like higher yield, improved quality and efficiency, reduced manual inspection costs, and shorter production cycles.

A specific example of virtual metering: During semiconductor production, inaccurate pressure control during wafer polishing can lead to excessive film thickness. Virtual metering tools establish the relationship between film thickness and other parameters, guiding operators to adjust settings for optimal results. This enables true online measurement, advancing the semiconductor industry.

However, a critical issue remains in the intelligent transformation of manufacturing: how can small and medium-sized enterprises (SMEs) undertake such upgrades? Yang Xiaoliang commented:

"These tools enable various enterprises, such as those with industry-knowhow engineers or basic automation capabilities, to unleash their potential. For example, an automated factory can transform into an 'industrial geek' factory, empowering industry experts."

"China is not yet a manufacturing powerhouse; many traditional manufacturing enterprises still rely on labor-intensive methods, facing risks like high energy consumption and equipment damage."

Intelligent Manufacturing, "Chip" Towards the Future—Intel's Intelligent Manufacturing Roundtable was held online on September 23. Yang Xiaoliang, Chief Architect of GTRONTEC, was invited to share practical insights and future perspectives.

"Thank you to Intel for providing this opportunity to gather and discuss the future of intelligent manufacturing. My presentation, 'Intelligent Manufacturing, Chip Towards the Future,' highlights GTRONTEC's efforts in applying industrial Internet technology to chip manufacturing and semiconductors."

GTRONTEC's Dongzhi Industrial Application Intelligent Platform is built on a foundation of public, private, or hybrid cloud infrastructure. From the bottom up, the platform connects with traditional factory equipment, such as SCADA (Supervisory Control and Data Acquisition) systems, and software like MES (Manufacturing Execution System), ERP (Enterprise Resource Planning), and PLM (Product Lifecycle Management).

Data collected via edge devices is sent to the platform to uncover deeper insights. Industry experience and knowledge are used to build industrial algorithm and model libraries, packaged as microservices. Additionally, aPaaS leverages the platform to develop industrial apps.

GTRONTEC currently offers numerous end-to-end databases, such as the Equipment Health Management System (EHM) for digital factories and the machine vision system Dongzhi Tianshu. On the factory floor, machine vision products can automatically detect defects, while the Multi-Factor Analysis (MFA) tool delves into data to model relationships between results and parameters.

These technologies rely on three foundations: computing, transmission, and storage. Computing: Intel Xeon processors provide stable computational power. Transmission: Intel Ethernet technology meets network demands through scalability, accelerating high-priority applications and ensuring rapid data transfer between cloud infrastructures.

Storage: Intel's Optane technology includes memory and SSDs, both critical components of cloud infrastructure.

As a benchmark in the semiconductor industry, how does GTRONTEC contribute back to this sector?

One of GTRONTEC's flagship products is virtual metering. In actual production, many abnormal defects cannot be resolved through manual experience alone, as a single defect may relate to dozens of parameters. Big data analytics can uncover these relationships, leading to benefits like higher yield, improved quality and efficiency, reduced manual inspection costs, and shorter production cycles.

A specific example of virtual metering: During semiconductor production, inaccurate pressure control during wafer polishing can lead to excessive film thickness. Virtual metering tools establish the relationship between film thickness and other parameters, guiding operators to adjust settings for optimal results. This enables true online measurement, advancing the semiconductor industry.

However, a critical issue remains in the intelligent transformation of manufacturing: how can small and medium-sized enterprises (SMEs) undertake such upgrades? Yang Xiaoliang commented:

"These tools enable various enterprises, such as those with industry-knowhow engineers or basic automation capabilities, to unleash their potential. For example, an automated factory can transform into an 'industrial geek' factory, empowering industry experts."