Industrial Internet 'Expert' Insight | He Jun: Industrial Internet Value Highlights, APaaS Platform Plays a Key Role

To accelerate the development of China's Industrial Internet and promote its industry-university-research-application collaboration, the Industrial Internet Industry Alliance (AII) was established on February 1, 2016, under the guidance of the Ministry of Industry and Information Technology. Initiated by over a hundred organizations from industries, information and communication, and the internet sectors, AII serves as an influential ecological carrier for the Industrial Internet in China.

On its fifth anniversary, AII launched the Industrial Internet 'Expert' Insight series, themed 'Trend Insights & Path Exploration,' inviting industry leaders to share their practical experiences and deep thoughts on the future development of the Industrial Internet.

As Vice Chairman of AII, GTRONTEC CEO He Jun was invited to share insights from years of experience in the Industrial Internet field. The original text follows:

01

The Trend of Industrial Internet 'Shifting from Virtual to Real' Becomes More Evident

After initial exploration, China's Industrial Internet has entered a phase of 'shifting from virtual to real,' marked by several changes. First, a return to business essence, focusing on applications rather than platforms to solve production pain points and deliver real value. Applications now extend from external links like sales and logistics to internal ones like R&D, control, and inspection, with technologies like 5G, AI, and big data deepening their integration into production processes. In AII's 2020 Industrial Intelligence Application Case Collection, GTRONTEC's 'AI-Based Automatic Defect Classification System' was selected alongside eight other AI applications from industries like chemicals, energy, automotive assembly, and steel manufacturing, showcasing the practical impact of the Industrial Internet. This system replaces manual defect classification in LCD panel production, achieving:AI recognition speed increased by 5-10 times, accuracy improved from 85% to over 90%;

Over 50% labor replaced, generating annual economic benefits exceeding ten million.

Second, the Industrial Internet is entering a vertical industry development phase, with platforms and service providers focusing on tailored solutions for different sectors. Competitions now feature entries from nearly thirty industries, including raw materials, consumer goods, equipment, and electronics, even extending to agriculture, finance, and tourism. Experts note the clear industry-specific nature of these solutions. GTRONTEC's 'Semiconductor Manufacturing R2R Ultimate Quality Control Solution' won the second prize in the 2020 China Industrial Internet Competition. Semiconductor batch processes are highly complex, and the R2R solution, based on the Industrial Internet, uses data-driven feedback control and local optimization to compensate for production disturbances and improve quality. Deployed at TCL CSOT Wuhan t3 and t4 factories, it significantly reduces production variation, increasing annual profits by over 5 million. Third, the focus shifts from fragmented, point-based applications to comprehensive systems that address issues holistically. For example, the R2R solution covers the entire semiconductor yield improvement process, including data acquisition, full inspection, and real-time feedback control, forming a closed-loop quality control system. The Industrial Internet is increasingly driving core skill enhancement in manufacturing, fostering revolutionary changes.02

Industrial Internet Platform Value Highlights, Supporting Vertical and Horizontal Business Development

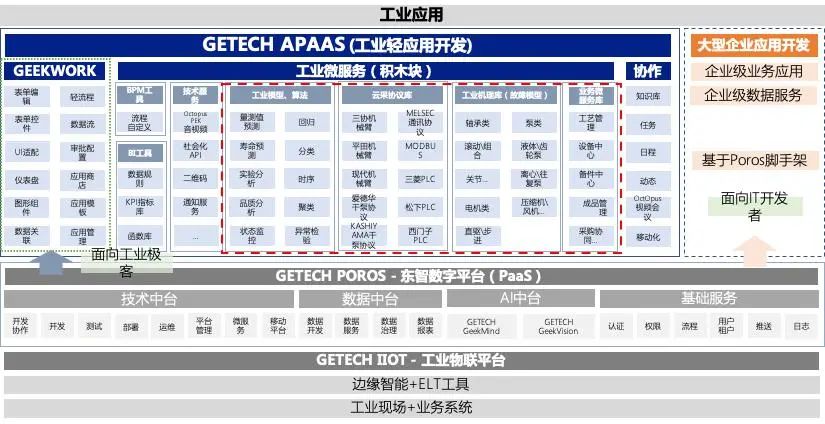

The global pandemic has tested manufacturers, pushing them to accelerate digital transformation centered on the Industrial Internet. Large enterprises face the challenge of deploying deep solutions across full scenarios and chains, from supply to production to delivery, requiring vertical development and innovation. SMEs, previously hindered by high costs and delivery difficulties, are now compelled to adopt Industrial Internet solutions. For them, low-cost, rapid-delivery SaaS applications are preferable, allowing gradual investment based on initial results. GTRONTEC leverages its Dongzhi APaaS platform, using low-code/no-code methods to reuse business components, model algorithms, and industrial mechanisms as microservices. Dongzhi APaaS Platform Architecture Vertically, GTRONTEC delves into the semiconductor industry, integrating the industrial chain and achieving a complete functional chain through projects like equipment interconnection, predictive maintenance, quality analysis, and intelligent visual inspection, yielding both implicit and explicit benefits such as reduced改造 costs, increased annual benefits, and fewer quality issues. Horizontally, it distills experiences from semiconductor cases into the APaaS platform, forming lightweight applications with industry know-how and agile development, delivered as SaaS to empower SMEs in iterative Industrial Internet construction. For instance, a machining enterprise subscribed to Dongzhi Equipment Health Management (EHM) suites as needed, achieving smart diagnosis, maintenance, prediction, remote support, and spare parts forecasting. Deployment increased production output by 3%-5%, reduced abnormal downtime by 10%-20%, and cut maintenance costs by 10%-15%.

Dongzhi APaaS Platform Architecture Vertically, GTRONTEC delves into the semiconductor industry, integrating the industrial chain and achieving a complete functional chain through projects like equipment interconnection, predictive maintenance, quality analysis, and intelligent visual inspection, yielding both implicit and explicit benefits such as reduced改造 costs, increased annual benefits, and fewer quality issues. Horizontally, it distills experiences from semiconductor cases into the APaaS platform, forming lightweight applications with industry know-how and agile development, delivered as SaaS to empower SMEs in iterative Industrial Internet construction. For instance, a machining enterprise subscribed to Dongzhi Equipment Health Management (EHM) suites as needed, achieving smart diagnosis, maintenance, prediction, remote support, and spare parts forecasting. Deployment increased production output by 3%-5%, reduced abnormal downtime by 10%-20%, and cut maintenance costs by 10%-15%.

03

Software Platform Trend Evident, Domestic Industrial Software Accelerates Development

Industrial software is evolving from tools to platforms with the maturity of the Industrial Internet. Traditional software supports efficiency and quality improvements across R&D, production, testing, maintenance, and remote services. Future platform-based software will also enable business model transformations, such as collaborative R&D, personalized customization, networked manufacturing, online maintenance, and time-sharing leasing. Previously, development was limited by insufficient microservice modules in professional fields. Now, microservices on Industrial Internet platforms encapsulate industrial principles like technology, knowledge, experience, and models, speeding up software delivery by 8 times and reducing costs to 20%-40%.The COVID-19 outbreak in early 2020 posed challenges for production delivery, especially for industries reliant on industrial robots, as on-site maintenance was hindered. GTRONTEC quickly developed a 'Industrial Robot Remote Real-Time Maintenance APP' on its Dongzhi Industrial Application Intelligent Platform using low-code, drag-and-drop methods, deploying it in 40% of the average development time to aid rapid resumption of work. This app won the 2020 China (Tianjin) Industrial APP Innovation Competition. Subsequently, GTRONTEC joined the 'Million Industrial APP Ecosystem Cultivation Plan,' opening thousands of mechanism models on its platform to third-party developers, partners, and clients, promoting open-source industrial software生态 construction and fostering an innovative, shared, collaborative environment.

In the future, we will continue to accumulate industrial models, service modules, and development tools to empower customers in self-service tool development, speeding up deployment and innovation in industrial software.04

IT & OT Integrated Talent Development is Key

The essence of the Industrial Internet is to achieve data integration through IT and OT fusion, leading to fundamental management changes. However, with numerous manufacturing industries and complex processes, achieving this requires not only industry experts but also IT professionals with deep digital R&D backgrounds. The trend of IT-OT integration is evident in manufacturing and academia, with activities like 'Internet+' competitions encouraging cross-disciplinary development among students. GTRONTEC's talent strategy emphasizes 'talent integration' through external recruitment and internal transfers, fostering a diverse, innovative team. Since mid-2019, GTRONTEC has implemented hundreds of Industrial Internet projects, including innovative ones. Manufacturers will eventually experience the results of IT-OT integration: factory personnel become adept at using software platforms for equipment maintenance and quality analysis, moving away from traditional management methods to tech upgrades and new IT tools.Amid the Industrial Internet wave, GTRONTEC has witnessed rapid changes, with rich application scenarios in China driving fast development. From our practice, excellent platforms are deepening industry engagement with a 'depth over speed' mindset, learning, researching, and innovating. With efforts from these enterprises and new forces, China's Industrial Internet will overcome challenges and develop steadily. The time will come to ride the wind and break the waves, setting sail to conquer the seas!