Industrial Internet X AI Empowers Oil and Gas Pipeline 'Unmanned' Stations -- Replication

China began attempting unmanned substations as early as the 1950s, but due to technical, economic, and management constraints at the time, it was not widely promoted. Later, the development of computer technology, communication technology, and control technology laid the foundation for unmanned substations. In 1996, the first 110kV comprehensive automation substation in the national power system was put into operation in the Xingtai grid, and unmanned substations gradually gained promotion across the country.

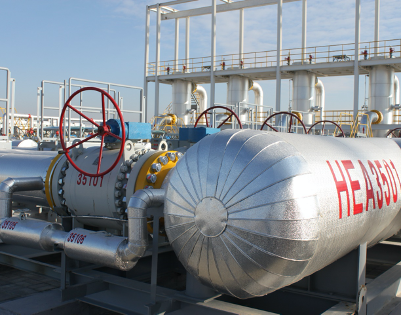

Compared to unmanned stations in power grid dispatching, the complexity of unmanned stations for long-distance oil and gas pipelines is much higher because the transported medium consists of physical substances (crude oil, refined oil, natural gas, etc.). This is reflected in:

More complex control systems; a wide variety of station equipment; higher safety protection requirements; greater daily maintenance and repair workload; higher anti-terrorism and security requirements...

Currently, domestic oil and gas production stations and long-distance pipeline stations technically meet the conditions for unmanned operation. Under this premise, GTRONTEC is gradually promoting the construction of unmanned stations for oil and gas production and natural gas pipelines using Industrial Internet platform technologies such as IoT, edge computing, AI, and big data analytics.

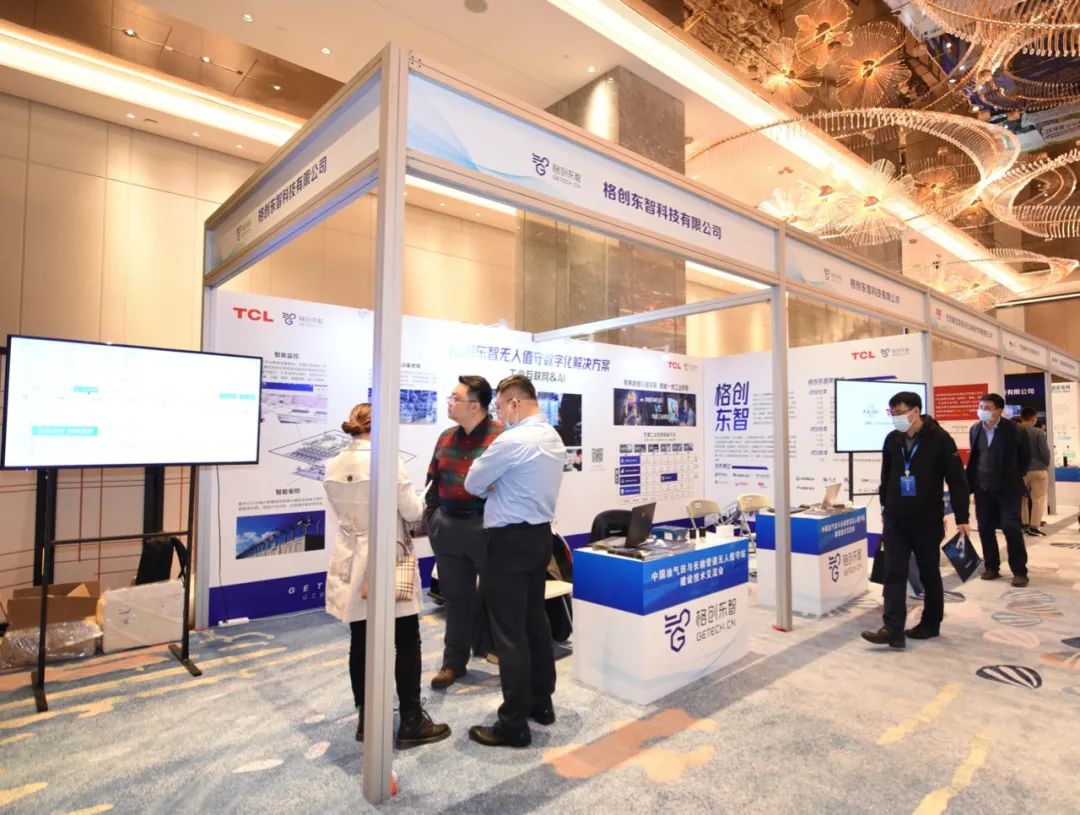

On March 17, the 'China Oil and Gas Field and Long-Distance Pipeline Unmanned Station Construction Technology Exchange Conference and Drone Technology Seminar,' hosted by the Petroleum Storage and Transportation Professional Committee of the China Petroleum Society, the West-East Gas Pipeline Branch of the National Oil and Gas Pipeline Network Group, and the East China Branch of the National Oil and Gas Pipeline Network Group, was successfully held in Hangzhou. Liu Qirong, Solution Director of GTRONTEC, was invited to participate and delivered a keynote speech, introducing GTRONTEC's 'one core' and 'three details' for empowering unmanned operations.

One Core: Industrial Internet X AI

As an emerging technological framework, the Industrial Internet, based on the high reliability and safety requirements of the industrial sector, can provide a complete set of technical solutions for unmanned station scenarios.

The application of AI technology in unmanned stations is the finishing touch on the Industrial Internet framework. The use of AI can elevate unmanned operations from 'pseudo' unmanned (remote control and operation by humans) to 'true' unmanned (self-response, self-adjustment, and self-processing by the station system), breaking through the fixed mindset of existing unmanned operations.

Three Details

Detail One: Comprehensive Perception of Station Information

Using a complete IoT solution, comprehensive data from the station can be obtained, including but not limited to: production data, equipment data, environmental data, energy consumption data, security data, fire safety data, and new system data.

Information is a critical input for analyzing and responding to events. The more comprehensive the data perception, the more complete the data for analysis, and the more reasonable the final response and handling methods.

Detail Two: In-Depth Analysis of Station Status

Current station-related systems have achieved some simple analysis functions. For example, new security systems can provide not only video surveillance and real-time playback but also features such as virtual perimeters and intrusion alarms.

However, these systems lack in-depth AI applications, specifically those based on mechanistic models. Taking the security system as an example, the security system of an unmanned station needs to analyze the behavior of people entering and exiting the station’s surroundings based on real-time information and data from various security subsystems, combined with AI models, to predict potential dangerous behaviors in advance. At the same time, it must perceive and comprehensively judge abnormal phenomena around and within the station, such as loud noises or flashes, to determine the real-time security status.

In-depth analysis of station status refers to using AI technology to conduct comprehensive and thorough analysis of the acquired station information, much like the human brain, to make accurate analyses and judgments.

Detail Three: Rapid Response to Station Events

Rapid response to station events is an extension of AI technology application and also places higher demands on the edge computing capabilities and cloud-edge integration of the unmanned central control system. 'Rapid' response requires both levels to work simultaneously to effectively handle events occurring at the station.

The unmanned operation of long-distance oil and gas pipeline stations is a typical case of digital transformation in the long-distance oil and gas transportation field. Like the digital transformation of traditional industries, it also needs to go through the three stages of digitization, datafication, and intelligence.

Currently, the final step to攻克 in unmanned stations is how to achieve intelligent, truly unmanned operation. Industrial Internet and AI technologies will undoubtedly be excellent tools to assist in this攻坚.

Currently, based on Industrial Internet and AI technologies, GTRONTEC has implemented multiple unmanned digital solutions, including:

Intelligent Monitoring

Using GTRONTEC IoT platform data acquisition modules, edge computing modules, and EHM module drag-and-drop configuration applications to achieve real-time visualization of equipment data and control system data, process flow visualization, and control action visualization, including separation, metering, pressure regulation, equipment start-stop, valve opening, etc.

Intelligent Equipment Management

Using GTRONTEC EHM equipment health management modules and edge computing AI industrial models to achieve 360-degree equipment档案 management, intelligent equipment预警, intelligent equipment diagnosis, and intelligent equipment prediction evaluation.

Intelligent Security

Using IoT edge computing modules and video AI models to achieve functions such as electronic fencing, hazard source identification, dangerous behavior identification, and emergency operation triggering.

Intelligent Inspection

Using inspection robots and video/audio AI models for environmental data collection (natural environment, cabinet room environment) and supplementary station data collection (safety valve temperature, flange leakage, abnormal noise, etc.).

With TCL's 40 years of deep manufacturing基因, GTRONTEC is continuously empowering more industrial scenarios with the Industrial Internet technologies and experiences沉淀 from rich practical implementations.

After unmanned oil and gas pipeline stations, what will be the next challenge?

The future awaits.