Southern Daily: GeChuang DongZhi's Data Applications Empower Digital Transformation - Replication

Recently, Southern Daily's Industry Weekly prominently featured the 'Intelligent Transformation'—a special report on Guangdong's Industrial Internet In-depth Research 2.0. As a representative enterprise of the 'three major forces' in Guangdong's industrial internet development, GeChuang DongZhi was deeply covered by Southern Daily, showcasing its focus on empowering digital transformation in advanced manufacturing.

*The following content is reprinted from Southern Daily

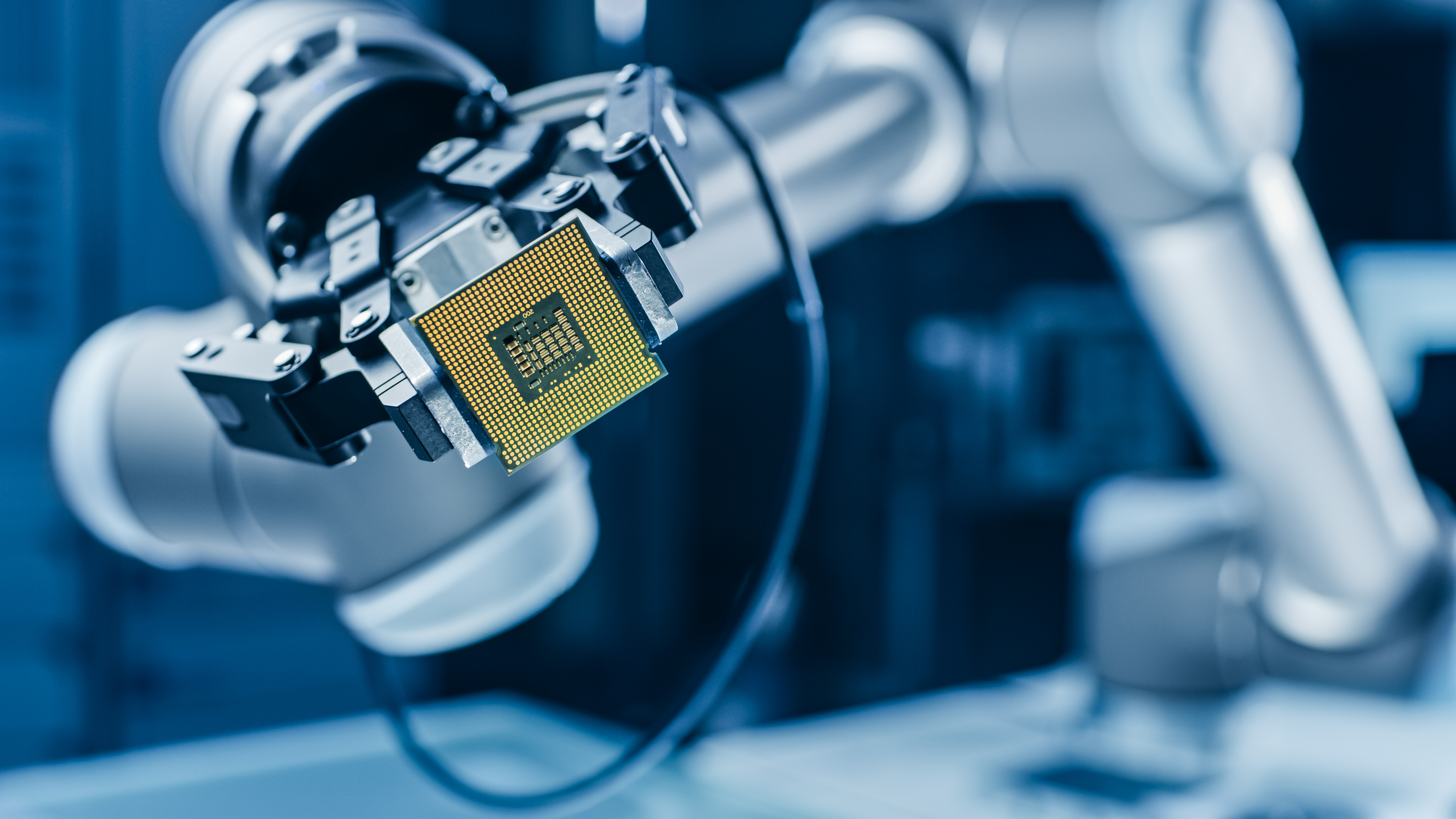

MFA multi-factor analysis modeling, AI-based Automatic Defect Classification system, AI visual inspection system, Equipment Health Management (EHM)... Today, in digital production lines across industries like semiconductors, automotive, and home appliances, such cutting-edge applications are 'taking root' in every digital detail of manufacturing, transforming the current industrial landscape.

These advanced applications bring tangible production benefits—'contributing direct economic benefits of tens of millions annually,' 'reducing equipment investment worth 30 million per year'... Behind these figures is an emerging star in the industrial internet realm—GeChuang DongZhi—gradually gaining attention from numerous industrial manufacturing enterprises.

Incubated and established by TCL in 2018, GeChuang DongZhi始终坚持 focuses on the production site, unlocking the value of industrial data, and empowering the digital transformation of advanced manufacturing, supporting the development of Guangdong's electronic information industry cluster and contributing to the 'Manufacturing Power' initiative.

Benchmark Product Leads: ADC Gives Panel Inspection 'Keen Insight'

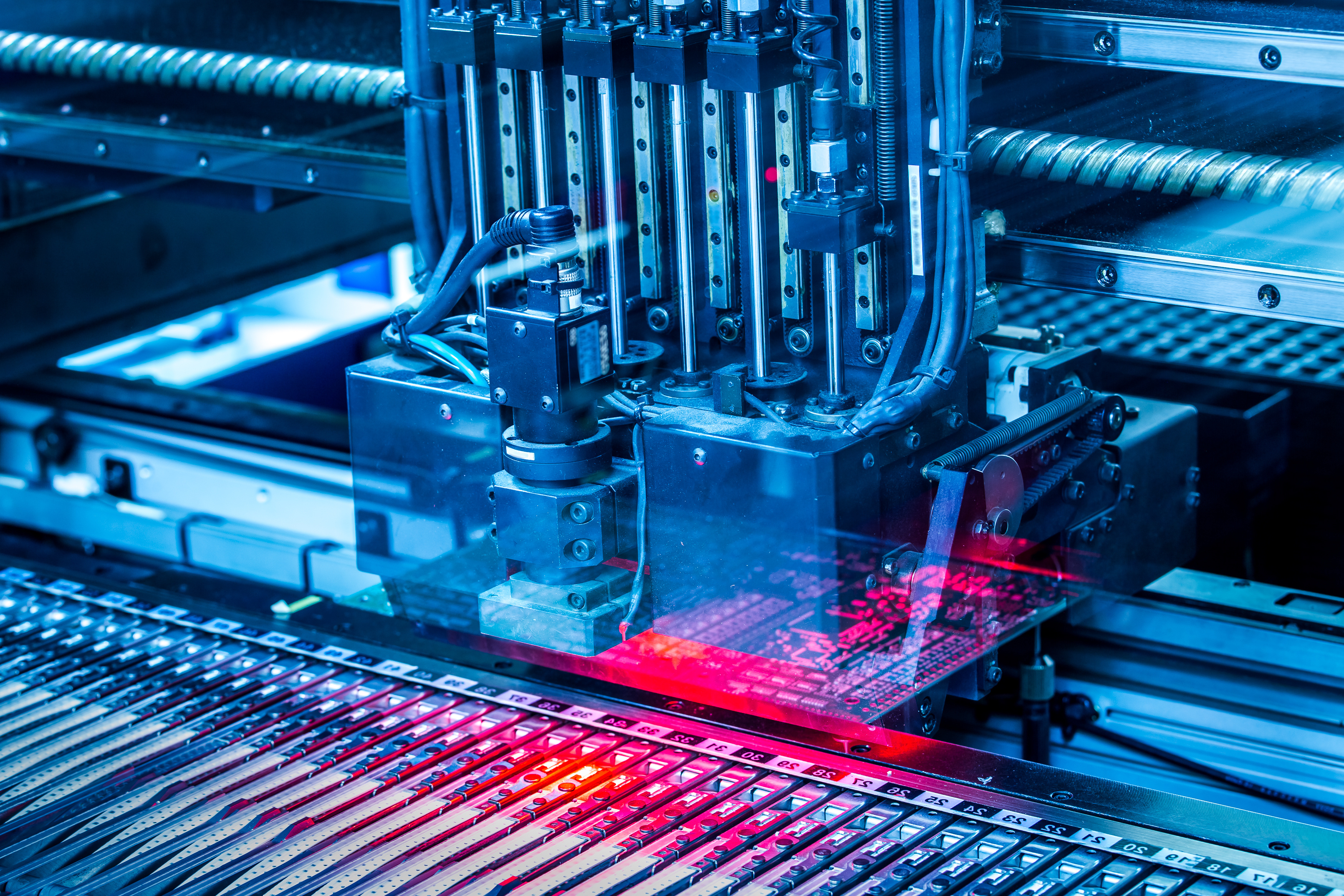

On the display panel production line of TCL CSOT, a representative advanced manufacturing enterprise in Guangdong, the ADC (AI-based Automatic Defect Classification system) leaves no room for substandard products to go undetected; there is no possibility of 'passing off inferior ones as genuine.'

The ADC system developed by GeChuang DongZhi for TCL CSOT is the first truly implemented AI application in China's semiconductor display industry.

'In the production process, improving efficiency and yield rate is key. Using AI to replace the human eye aims to reduce errors from manual judgment. On the other hand, human experience varies, and we hope to solidify accumulated experience into algorithmic models to enhance accuracy,' said He Jun, CEO of GeChuang DongZhi.

Panels are precision instruments with very high requirements for product yield, but some subtle defects are微小 and hard to detect. In the past, on LCD panel production lines, industrial defect detection largely relied on manual judgment, with a dedicated department of employees examining images on computers. Using human eyes to judge results from AOI (Automatic Optical Inspection) equipment, classifying defects based on morphology to determine quality compliance, this环节 often faced several challenges: first, recruitment was particularly difficult, and training took time; second, the stability of manual judgment accuracy had room for improvement.

With the introduction of the ADC (AI-based Automatic Defect Classification system), the situation has changed significantly. It is reported that the ADC system utilizes big data, AI deep learning, machine vision, and other latest technologies to compare product images with a known defect image library, intelligently detecting defect types through advanced algorithmic models, automatically analyzing anomalies, and providing solutions. Integration of this system with existing inspection processes also allows for quick startup and operation of the solution.

'Compared to traditional manual inspection methods, detection efficiency has greatly improved, overall production efficiency increased by 6%;避免了 deviations caused by subjective human inspection, accuracy improved by 2%; reduced labor costs, comprehensive benefits increased by 15 million/year,' introduced on-site technicians at TCL CSOT.

Deepening Digital Solutions in the Semiconductor Industry Targeting Smart Manufacturing Pain Points

After launching benchmark applications, GeChuang DongZhi continued to delve into the semiconductor industry, expanding coverage to other areas within the sector, integrating the semiconductor industry chain, forming a complete functional chain, and implementing multiple application projects, such as equipment interconnection, predictive maintenance, industrial quality analysis and optimization, and intelligent visual inspection.

The R2R (Run to Run Control) extreme quality control solution is a standout achievement in this process, empowering企业数字化转型. 'Run' refers to batches in the production process; this solution continuously optimizes algorithms to keep equipment on the production line in the optimal production state.

R2R has three goals: ensuring process stability and consistency, reducing the impact of external factors on the process, and guaranteeing controlled quality fluctuations for stable production. In manufacturing fields with extreme demands for production efficiency and yield rate, such solutions are core to vitality. Semiconductor batch processes are considered among the most complex high-tech processes today, precisely due to issues like complex process steps, highly re-entrant processes, and difficulty in real-time quality control. Improving production yield in semiconductors is very challenging, but GeChuang DongZhi's R2R extreme quality control solution makes this difficult task more feasible.

'Industrial internet is a neural中枢; relying on data analysis, it can detect不良状况 in equipment at any time and adjust to the optimal state. This is much more efficient than previous manual经验调试, currently reducing manual debugging from at least 2 hours to 30 seconds自动调试, with much higher precision than manual methods, bringing huge real economic benefits,' analyzed Wang Jin, Chief Smart Manufacturing Consultant at GeChuang DongZhi.

In addition to hit products like the R2R extreme quality control solution, GeChuang DongZhi's smart energy management system EMS provides a complete digital management solution for reducing consumption in smart manufacturing, becoming an important support for energy management transformation in the semiconductor industry.

Technically, DongZhi EMS deeply integrates IoT platform, data mid-platform, edge computing, and部分 APaaS platform functions; in terms of scenarios, DongZhi EMS covers factory power distribution systems, photovoltaic storage stations, various automatic control systems, fire消防 systems, video security systems, environmental monitoring, and other comprehensive factory energy, environment, and safety management systems, providing a complete and powerful smart management platform for factory energy management, maximizing efficiency in energy, environment, and safety management. The system is expected to bring cost-saving benefits of tens of millions annually to enterprises.

If ADC (AI-based Automatic Defect Classification system), R2R (Run to Run Control) extreme quality control solution, and smart energy management system EMS are the fruits of GeChuang DongZhi's years of深耕 in the semiconductor industry, then products like multi-factor analysis MFA give wings to GeChuang DongZhi's efforts in cross-industry manufacturing digital transformation.

In the middle of last year, the Ministry of Industry and Information Technology officially announced a list of 125 excellent industrial internet APP solutions for 2019. GeChuang DongZhi won an award with its 'MFA Multi-Factor Analysis APP Application Solution.'

DongZhi MFA multi-factor analysis tool (hereinafter referred to as DongZhi MFA) is a self-developed multi-factor analysis modeling tool for industrial big data analysis, helping production engineers model efficiently and deeply mine data value. Using DongZhi MFA, digital solutions such as quality analysis, quality prediction, and equipment predictive maintenance can be achieved. DongZhi MFA is currently widely used in industries including panels, semiconductors, chips, electronics, automotive parts, energy, etc.

When faced with industrial data that is large in volume, high in dimensionality, and complex in relationships, manufacturing enterprises often struggle with单一 analysis methods, low efficiency in multi-dimensional data analysis, and a lack of data mining talent. DongZhi MFA was born to solve such problems.

In the chip industry, the CMP (Chemical Mechanical Polishing) process is affected by previous processes, with numerous influencing factors, frequent anomalies, greatly impacting product electrical parameters and yield rate. In the CMP process of a certain chip manufacturing enterprise, manual sampling of film thickness was previously required at stations, with results relying on employees' production experience and lacking unified standards; moreover, defect anomalies lacked effective analysis methods, product超差率 was high, and root cause定位 efficiency was low, seriously affecting capacity and yield improvement.

Digital solutions became the利器 to solve this难题. GeChuang DongZhi built an analysis modeling platform and intelligent optimization platform based on DongZhi MFA, achieving intelligent detection, real-time prediction of quality indicators, unifying and improving inspection standards, quickly locating anomaly causes, timely providing improvement suggestions, solving the困扰 of data completeness, real-time performance, and determinism in high-end manufacturing, and effectively enhancing capacity.

Prior to this, by using models established with DongZhi MFA, the virtual measurement system reduced the unit of defective products in液晶 panels from batches to individual pieces, bringing benefits of millions of yuan to TCL CSOT in just one year. This time, in the automotive manufacturing field, DongZhi MFA化身 as an invisible 'algorithm engineer,' helping process engineers use algorithmic models to monitor, warn, and optimize equipment process parameters, thereby improving product quality and efficiency.

It can be said that today's GeChuang DongZhi has accumulated深厚的 industrial mechanism models from丰富的 practical cases, enabling cross-industry empowerment. It has created over a hundred digital transformation cases in more than thirty industries including integrated circuits, new displays, semiconductor discrete devices, semiconductor materials, 3C electronics, communication equipment, new energy, aircraft manufacturing, petrochemicals, automotive parts, pharmaceuticals, machinery, etc.,孵化 multiple universal 'star products' such as DongZhi MFA multi-factor analysis, DongZhi EHM equipment health management, DongZhi Tian Shu AI visual inspection system, etc. Several of these products and their derivative applications have been recognized多次 by authoritative institutions and official competitions. In addition to the 'MFA Multi-Factor Analysis APP Solution,' the 'Industrial Robot Remote Operation and Maintenance Solution' won the championship in the special competition of the 2020 China (Tianjin) Industrial APP Innovation Application大赛; the 'Semiconductor R2R Extreme Quality Control Solution' won third place nationally in the Second China Industrial Internet大赛...

To better promote the digital transformation of the electronic information industry cluster, GeChuang DongZhi, leveraging its years of technical沉淀 in the industry, along with consortium partners, is actively guiding upstream and downstream players in the industrial cluster, production-supply-sales, and small and medium-sized enterprises onto the platform. By integrating industries regionally and聚合 applications by sector, it is坚定不移地 implementing the decisions and deployments of the provincial party committee and government, doing a good job in serving the digital transformation of manufacturing, and contributing its strength to the high-quality development of manufacturing in the province.