How Does the Petrochemical Industry Respond to the Era of 'Carbon Neutrality'?

As global warming becomes an indisputable fact, the international community has largely reached a consensus—carbon neutrality. To this end, China has formulated its own emission reduction roadmap: reaching peak carbon emissions between 2021 and 2030, rapidly reducing carbon emissions from 2031 to 2045, and achieving deep carbon neutrality from 2046 to 2060.

According to relevant statistics, the petrochemical, power, steel, building materials, non-ferrous metals, metallurgy, and transportation industries are key carbon-emitting sectors in China, collectively accounting for over 74% of the nation's total carbon emissions. Deep decarbonization will inevitably require profound transformations in corporate production, operations, management, and after-sales services.

As production equipment is fundamental to the survival of industrial enterprises, companies will inevitably need to address changes in equipment efficiency: using more environmentally friendly raw materials, achieving lower energy consumption per unit output, extending equipment lifespan, and reducing equipment operation and maintenance costs.

How can petrochemical enterprises further enhance equipment efficiency?

In May, the "2021 (Second) China Petrochemical Equipment Maintenance Technology Conference," hosted by the China Chemical Industry Society, was grandly held in Dalian. Wang Yuqing, Deputy Secretary-General of the China Chemical Industry Society and Chairman of the Petrochemical Special Committee, attended and presided over the conference. Over 500 leaders, experts, scholars, technicians, and managers from the petrochemical equipment maintenance field gathered to exchange experiences and discuss new insights, concepts, achievements, and practices in equipment maintenance, collectively strategizing to improve equipment efficiency.

As an outstanding supplier of industrial internet solutions for the petrochemical industry, GTRONTEC's Senior Manager of Equipment Health Diagnostics, Chen Shiqi, was invited to attend and deliver a keynote speech on GTRONTEC's integrated solution for the holistic management of static and dynamic equipment in the petrochemical industry.

Have you encountered these scenarios:

When you need to query equipment data, you only have piles of documents

When you need to understand equipment operating parameters, you only have various complex subsystems

......

This is a common pain point for equipment managers in industrial enterprises—a "chasm" that must be crossed in equipment management.

Leveraging deep experience in industrial equipment management, GTRONTEC proposes a "four-step" solution for the integrated management of static and dynamic equipment in the petrochemical industry, helping enterprises effectively enhance equipment management efficiency:

STEP 1: Ensure equipment is always accessible: Integrate existing static data systems related to equipment, such as paper/electronic document systems and EAM/ERP/SAP, to achieve multidimensional management of static equipment data, ensuring data is always queryable.

STEP 2: Ensure equipment is always visible: Combine the comprehensive management of existing dynamic equipment data, enabling data interaction between systems like PLC/MES/DCS/SCADA, and build an integrated platform for dynamic data management, analysis, and evaluation to ensure real-time access to equipment operating data.

STEP 3: Ensure equipment operating status is always controllable: Controllability of equipment operating status is fundamental to production control. By integrating dynamic data from existing equipment monitoring and management systems and适时 adding data acquisition units, build a comprehensive dynamic data management system to evaluate equipment health indices, predict residual equipment life, and create a flexible and efficient spare parts supply system in conjunction with the company's spare parts inventory, improving overall equipment efficiency, reducing capital tied up in spare parts, and increasing capital turnover.

STEP 4: Ensure equipment benefits steadily improve: All management optimizations related to equipment ultimately aim to improve equipment efficiency. Optimizing equipment operating parameters is crucial for enhancing efficiency. By fully integrating equipment process parameter data and combining it with the static and dynamic data from the first three steps, gradually optimize equipment operating parameters to improve overall equipment benefits.

Based on GTRONTEC's "four-step" equipment management strategy, a comprehensive multidimensional equipment management system has been established, providing personalized equipment management data evaluation applications for managers with different permissions and offering strong data support for corporate decision-making and optimization.

GTRONTEC's integrated static and dynamic equipment management system comprehensively covers multidimensional data management for static equipment like tanks, facility structures, and pipelines, as well as dynamic equipment like turbines, compressors, pumps/fans, helping enterprises improve overall equipment efficiency.

Currently, GTRONTEC's integrated static and dynamic equipment management solution has been widely applied in the petrochemical industry, such as pipeline corrosion monitoring, tank stress-strain monitoring, reciprocating compressor comprehensive monitoring, and predictive maintenance of pumps.

Taking the management of a drying drum drive component in a petrochemical enterprise as an example, the system comprehensively monitors equipment operating parameters and uses a three-axis wireless vibration-temperature integrated monitoring system to evaluate the health status of the drive system. In February 2020, the system diagnosed damage to the non-drive side bearing of the second shaft of the gearbox. The overall equipment health index was 74, with no significant abnormal noise during operation, normal operating temperature, and an estimated residual life of at least 5 months.

Since the enterprise could not replace the gearbox components on-site and needed to return it to the factory for repair, but had no backup machine and a preparation cycle of at least 5 months, the system triggered the company to proactively purchase a backup machine to avoid delaying the production cycle. The backup machine arrived in August 2020, and the enterprise organized the equipment replacement. The disassembly results after factory repair were consistent with the system's diagnosis.

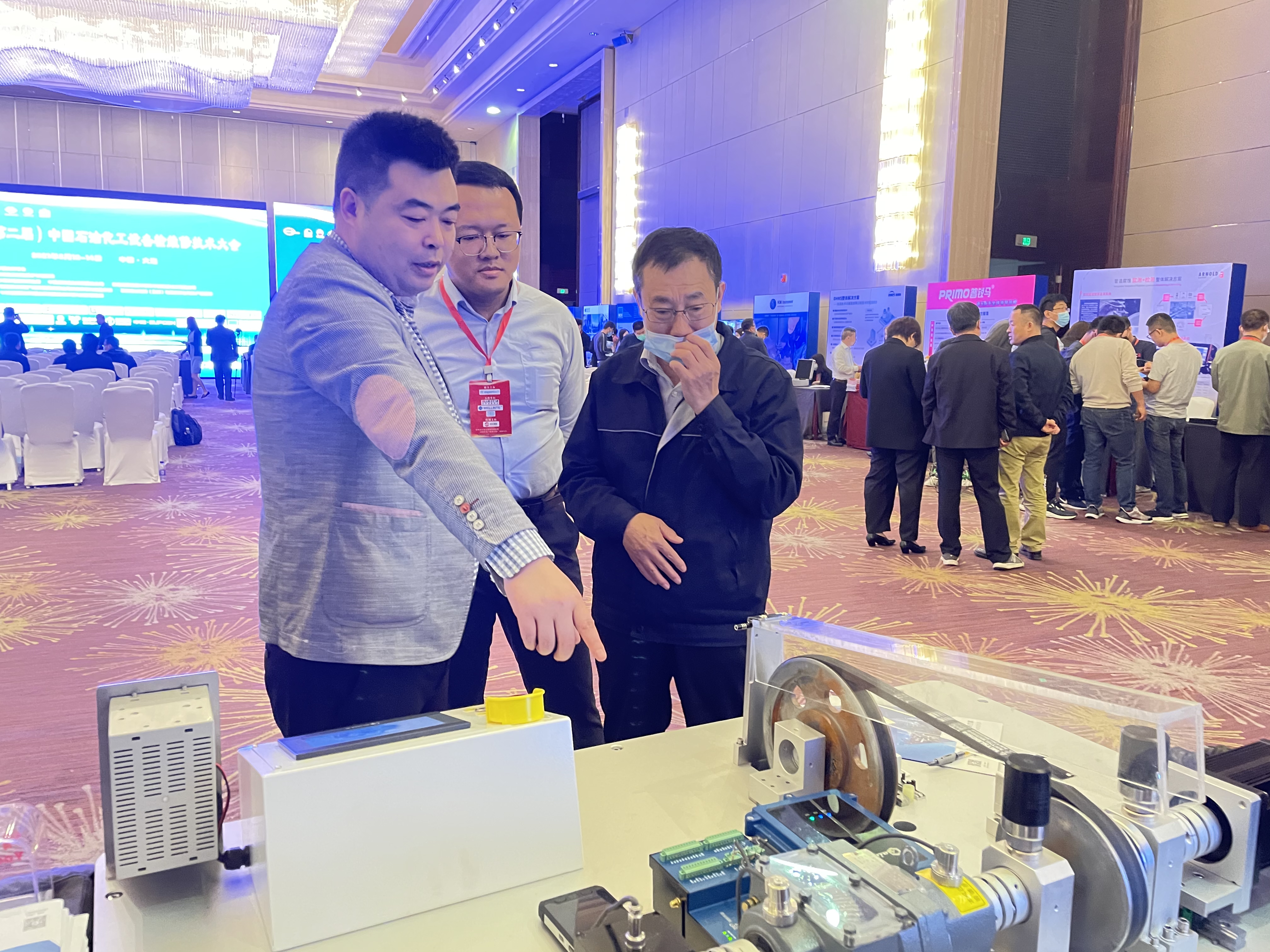

At the conference, GTRONTEC's booth attracted several top industry experts who stopped to view the displays.

First from right: Qian Guanghua, former professor-level senior engineer of the Chemical Department of Sinopec Tianjin Company

First from left: Ma Yan, former director and senior engineer of North Huajin Chemical Industries Co., Ltd.

Third from left: Chen Zhaohu, senior equipment engineer of CNOOC Huizhou Petrochemical Co., Ltd.

Several leading petrochemical enterprises engaged in in-depth communication with the GTRONTEC team to discuss cutting-edge technologies and development trends in petrochemical equipment management.