Another breakthrough in autonomous localization! Eastwise EHM achieves intelligent operation and diagnosis of semiconductor industry equipment

With the deep integration of new-generation information technology and manufacturing, the digitalization, networking, and intelligence levels of production equipment continue to improve.

Gechuang Eastwise's "star product"—Eastwise EHM equipment health management tool is designed for new-generation equipment management, achieving closed-loop management across all scenarios.

Recently, Eastwise EHM has made further breakthroughs in the semiconductor industry, with significant application effects on production equipment, highly recognized by customers.

Aiming at the unplanned downtime issue of the CVD (Chemical Vapor Deposition) PUMP in the factory, after on-site research, the Gechuang Eastwise team completed the deployment of Eastwise EHM rotating equipment status monitoring and fault intelligent diagnosis module within one day.

On-site PUMP equipment data is uploaded to the Eastwise EHM private cloud in real-time at a sampling frequency of 50,000 Hz per second, ensuring that subtle changes in vibration signals can be identified and analyzed by the Eastwise EHM expert system.

During over a month of operation, the built-in big data algorithms of the Eastwise EHM system effectively identified the degradation trend and intelligent fault diagnosis of the PUMP, with remarkable results.

The comprehensive performance of Eastwise EHM is more than twice optimized compared to similar foreign products.

In addition to advanced manufacturing such as semiconductors, Eastwise EHM can also be widely applied in industries like petrochemicals, mining, metallurgy, energy, water treatment, etc.

Project Background

Semiconductor panels belong to high-end manufacturing, with most on-site equipment imported from countries like Japan and South Korea, resulting in high equipment data acquisition costs.

Simultaneously, continuous production processes highly rely on equipment stability, with significant downtime losses.

The production plant is as large as 15 football fields, leading to enormous equipment inspection workloads.

If equipment defects are not discovered timely, it is prone to cause unplanned downtime, affecting production.

Taking the PUMP in this CVD process as an example, a large amount of solid dust is generated during production, causing the PUMP to jam.

Currently, due to the lack of effective equipment monitoring means, equipment is prone to unplanned downtime, causing nearly ten million yuan in economic losses to the enterprise each year.

Gechuang Eastwise Team Implementation Site

Solution

Due to the enclosed space of the equipment site, invasive data collection would cause unpredictable risks to the original equipment and process.

After evaluation, the customer decided to adopt Gechuang Eastwise's GVS series wireless vibration and temperature integrated sensor, fixed on the PUMP with magnetic adsorption for high-frequency data collection, and through the gateway, transmit the collected vibration and temperature data to the Eastwise EHM private cloud in real-time, combined with PUMP's own operating condition data for comprehensive analysis and evaluation of the equipment's operating status.

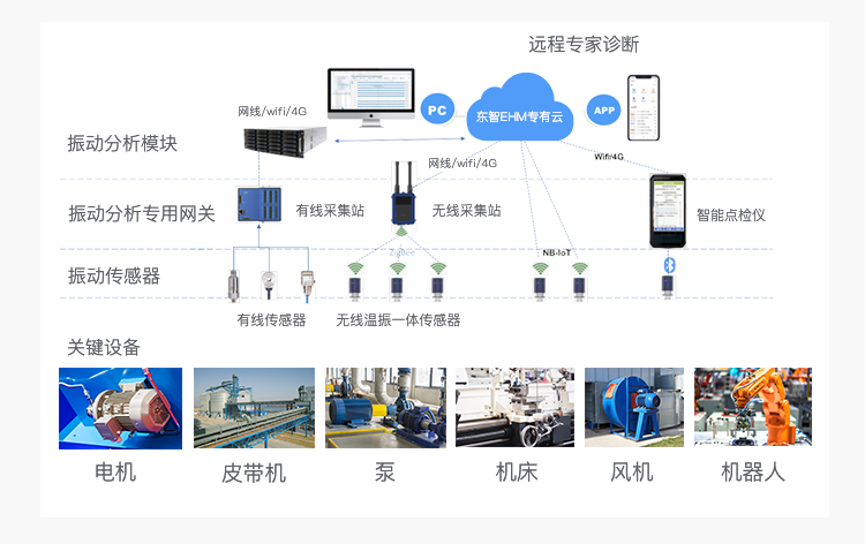

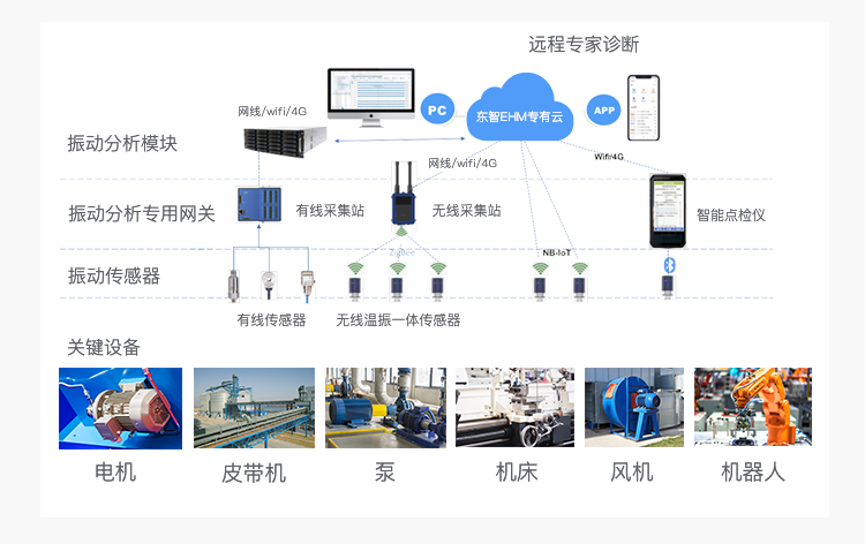

Solution Deployment Architecture Diagram

The advantages of this solution are:

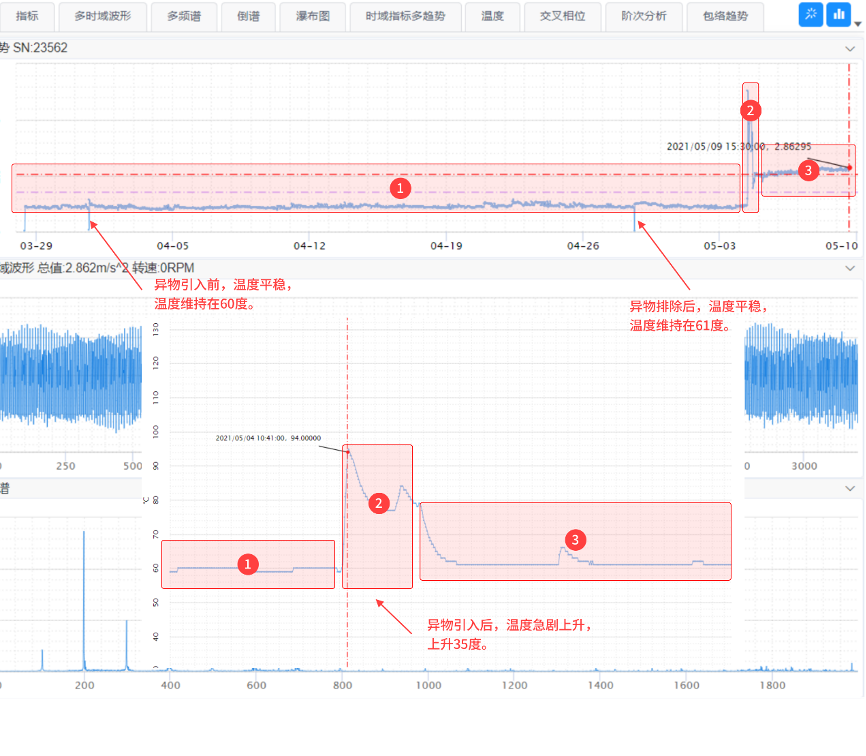

Equipment Health Assessment Report: Taking PUMP1 as an example--DP non-driven end vertical low-frequency measurement point vibration fluctuation is obvious, caused by foreign object introduction leading to slight rotor damage, its degradation can be roughly divided into three stages: Stage 1: March 28 (online) - May 4, equipment operation stable, no obvious degradation, but on March 31 (P1) and April 28 (P2), due to equipment reporting abnormal tail exhaust pressure, there were brief downtime, downtime inspection showed no obvious abnormalities, then restarted operation; Stage 2: May 4 09:30 - May 4 16:16, foreign object introduction (larger particles entered), causing PUMP poor exhaust, vibration sharply increased, accompanied by sharp temperature rise; Stage 3: foreign object removed, PUMP operation status improved, vibration sharply decreased, accompanied by temperature decrease, but the rotor has slight damage, vibration and temperature slightly increased compared to earlier, and began to slowly degrade. Pump status detection analysis chart

Pump status detection analysis chart

Health Status Assessment Conclusion: ① On May 4, due to foreign object introduction, causing DP rotor damage, currently in a slow degradation stage;

② DP will not run in the short term, no need for maintenance temporarily, strengthen monitoring; ③ The fluctuation in MB status is due to the transmission of DP's vibration energy, no obvious abnormalities found in MB. Case Summary

By high-frequency collection of PUMP operating status parameters, Eastwise EHM accurately determines the degradation trend of the PUMP, early warns customers of potential equipment faults, and performs timely repairs, avoiding the impact of unplanned downtime on production, effectively extending the equipment's service life.

Not only in advanced manufacturing, currently Gechuang Eastwise EHM's rotating equipment predictive maintenance solution has been widely applied in equipment of many industries such as petrochemicals, coal, steel, automotive, cement, etc., safeguarding the safe and efficient operation of industrial units and equipment.

Gechuang Eastwise's "star product"—Eastwise EHM equipment health management tool is designed for new-generation equipment management, achieving closed-loop management across all scenarios.

Recently, Eastwise EHM has made further breakthroughs in the semiconductor industry, with significant application effects on production equipment, highly recognized by customers.

Aiming at the unplanned downtime issue of the CVD (Chemical Vapor Deposition) PUMP in the factory, after on-site research, the Gechuang Eastwise team completed the deployment of Eastwise EHM rotating equipment status monitoring and fault intelligent diagnosis module within one day.

On-site PUMP equipment data is uploaded to the Eastwise EHM private cloud in real-time at a sampling frequency of 50,000 Hz per second, ensuring that subtle changes in vibration signals can be identified and analyzed by the Eastwise EHM expert system.

During over a month of operation, the built-in big data algorithms of the Eastwise EHM system effectively identified the degradation trend and intelligent fault diagnosis of the PUMP, with remarkable results.

The comprehensive performance of Eastwise EHM is more than twice optimized compared to similar foreign products.

In addition to advanced manufacturing such as semiconductors, Eastwise EHM can also be widely applied in industries like petrochemicals, mining, metallurgy, energy, water treatment, etc.

Project Background

Semiconductor panels belong to high-end manufacturing, with most on-site equipment imported from countries like Japan and South Korea, resulting in high equipment data acquisition costs.

Simultaneously, continuous production processes highly rely on equipment stability, with significant downtime losses.

The production plant is as large as 15 football fields, leading to enormous equipment inspection workloads.

If equipment defects are not discovered timely, it is prone to cause unplanned downtime, affecting production.

Taking the PUMP in this CVD process as an example, a large amount of solid dust is generated during production, causing the PUMP to jam.

Currently, due to the lack of effective equipment monitoring means, equipment is prone to unplanned downtime, causing nearly ten million yuan in economic losses to the enterprise each year.

Gechuang Eastwise Team Implementation Site

Solution

Due to the enclosed space of the equipment site, invasive data collection would cause unpredictable risks to the original equipment and process.

After evaluation, the customer decided to adopt Gechuang Eastwise's GVS series wireless vibration and temperature integrated sensor, fixed on the PUMP with magnetic adsorption for high-frequency data collection, and through the gateway, transmit the collected vibration and temperature data to the Eastwise EHM private cloud in real-time, combined with PUMP's own operating condition data for comprehensive analysis and evaluation of the equipment's operating status.

Solution Deployment Architecture Diagram

The advantages of this solution are:

GVS sensor is fixed on the PUMP with a magnetic base, will not damage the equipment, has no impact on equipment operation

GVS sensor is powered by a special battery, with a battery life of 3 years

The system uses wireless deployment, fast implementation, strong wireless performance, even in the high-temperature enclosed working environment of the PUMP, data transmission remains stable

Eastwise EHM system has built-in 30+ data analysis algorithms, can perform multi-dimensional analysis on monitoring data, accurately evaluate equipment status

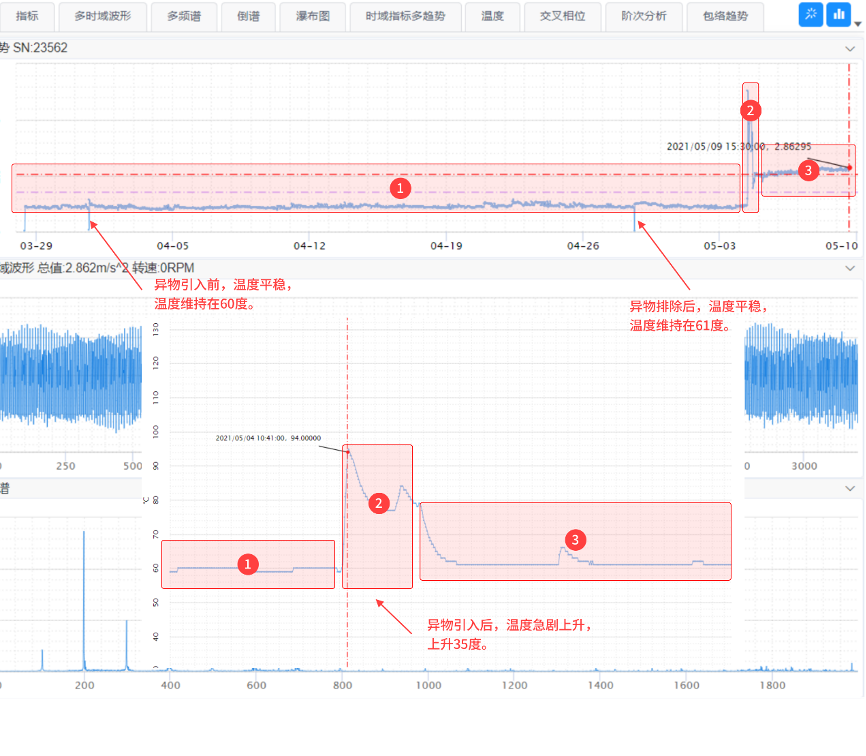

Equipment Health Assessment Report: Taking PUMP1 as an example--DP non-driven end vertical low-frequency measurement point vibration fluctuation is obvious, caused by foreign object introduction leading to slight rotor damage, its degradation can be roughly divided into three stages: Stage 1: March 28 (online) - May 4, equipment operation stable, no obvious degradation, but on March 31 (P1) and April 28 (P2), due to equipment reporting abnormal tail exhaust pressure, there were brief downtime, downtime inspection showed no obvious abnormalities, then restarted operation; Stage 2: May 4 09:30 - May 4 16:16, foreign object introduction (larger particles entered), causing PUMP poor exhaust, vibration sharply increased, accompanied by sharp temperature rise; Stage 3: foreign object removed, PUMP operation status improved, vibration sharply decreased, accompanied by temperature decrease, but the rotor has slight damage, vibration and temperature slightly increased compared to earlier, and began to slowly degrade.

Pump status detection analysis chart

Pump status detection analysis chart

Health Status Assessment Conclusion: ① On May 4, due to foreign object introduction, causing DP rotor damage, currently in a slow degradation stage;

② DP will not run in the short term, no need for maintenance temporarily, strengthen monitoring; ③ The fluctuation in MB status is due to the transmission of DP's vibration energy, no obvious abnormalities found in MB. Case Summary

By high-frequency collection of PUMP operating status parameters, Eastwise EHM accurately determines the degradation trend of the PUMP, early warns customers of potential equipment faults, and performs timely repairs, avoiding the impact of unplanned downtime on production, effectively extending the equipment's service life.

Not only in advanced manufacturing, currently Gechuang Eastwise EHM's rotating equipment predictive maintenance solution has been widely applied in equipment of many industries such as petrochemicals, coal, steel, automotive, cement, etc., safeguarding the safe and efficient operation of industrial units and equipment.