Geek Park: GeChuangDongZhi Industrial AI Visual Inspection 'Boosting' Advanced Manufacturing

GeChuangDongZhi was recognized by IDC as a 'Typical Service Provider in China's Industrial AI Visual Inspection Software and Solutions Market,' creating AI visual inspection systems for industry leaders such as TCL CSOT and Gree Electric.

*This article is sourced from Geek Park

Traditional quality inspection often relies heavily on manual labor, with issues such as long training cycles, high training costs, inconsistent evaluation standards, and low accuracy rates.

With the advent of the digital era, technologies like AI and IoT are gradually being applied to traditional quality inspection, helping to upgrade inspections, liberate productivity, and achieve cost reduction and efficiency improvement.

In the 'Industrial Internet Research' regularly published by the global authoritative consulting firm IDC, the recent focus on industrial AI visual inspection has attracted significant market attention and vendor participation due to its relatively emerging market and clear ROI. GeChuangDongZhi was selected as a 'Typical Service Provider in China's Industrial AI Visual Inspection Software and Solutions Market' with its TianShu AI Visual Inspection product.

Incubated by TCL, a leading enterprise with 40 years of experience in advanced manufacturing, GeChuangDongZhi has focused on advanced manufacturing and production sites since its inception, empowering the value realization of industrial data. Today, it has developed several 'star products,' such as DongZhi MFA Multi-Factor Analysis, DongZhi EHM Equipment Health Management, DongZhi EMS Energy Management System, and DongZhi TianShu AI Visual Inspection System, creating hundreds of innovative digital transformation cases across more than 30 industries.

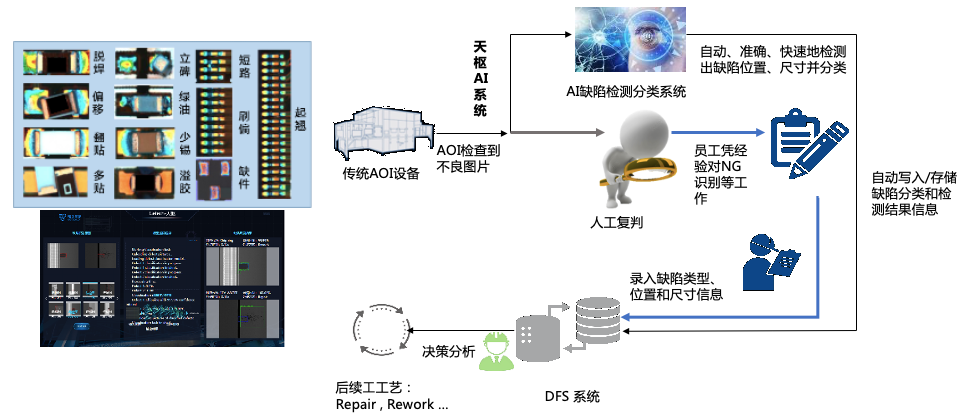

GeChuangDongZhi’s TianShu AI Visual Inspection System specializes in industrial AI inspection in fields such as semiconductor display and 3C manufacturing. It features an industrial visual deep learning engine integrating 'sensing, storage, computing, and cognition,' creating an integrated data collection solution of 'image + video + optics' and establishing a 360-degree data information database. It includes a tens of millions-level industry feature database to improve inspection accuracy and offers a multi-task, composite toolkit covering various industrial inspection application scenarios.

Currently, the TianShu AI Visual Inspection System has been deployed in multiple industrial scenarios. Based on this, the ADC (AI Automatic Defect Classification) system implemented in TCL CSOT’s production line is the first truly deployed AI application in China's semiconductor display industry. Compared to traditional manual inspection methods, the ADC system significantly improves inspection efficiency, replacing over 50% of manual labor; AI recognition speed increases by 5-10 times, and accuracy rises from 85% with the human eye to over 90%, expected to bring TCL CSOT an annual benefit of 15 million yuan.

In recent years, GeChuangDongZhi has established partnerships with several leading companies on AI visual inspection projects. For example, the 'AI Replacement Solution'—Online Intelligent Quality Analysis System developed for Gree Electric, a leader in the 3C electronics industry, applies the TianShu AI Visual Inspection System to Gree’s SMT production line. It inspects the quality of SMT placement and reflow soldering, reduces the misjudgment rate of post-reflow AOI equipment, and minimizes manual re-inspection labor. It enables device interaction, real-time monitoring of equipment status, accurate analysis of product quality, output of quality information for分流 control and quality analysis reports, all aimed at quality improvement.

After the deployment of the TianShu AI Visual Inspection System, it greatly improved the production efficiency of quality inspection on Gree’s SMT production line, reduced manual labor, ensured consistency in product quality inspection, and enhanced product quality. Additionally, the TianShu AI Visual Inspection System can be flexibly deployed on various production lines, quickly implemented without major changes to customer processes. Equipped with GeChuangDongZhi’s self-developed inference and training platforms, it enables cluster deployment, autonomous operation and maintenance, and rapid model optimization, comprehensively addressing the pain points of AI technology application.

As of now, the re-inspection rate on Gree’s SMT production line has been reduced to below 5%, cutting 80% of manual re-inspection work, with an expected annual direct benefit of millions of yuan.

This marks another breakthrough for GeChuangDongZhi with a leading client in the 3C electronics field and a milestone for the application of GeChuangDongZhi’s TianShu AI product in the SMT industry.

As the pace towards 'Smart Manufacturing in China' accelerates, intelligent technologies will be applied to more industrial scenarios. GeChuangDongZhi will continue to refine more innovative products, making manufacturing no longer 'traditional' and contributing to the development of smart manufacturing.