Supporting Carbon Peak, GTRONTEC Dongzhi Creates Equipment Health Management Solution for Tianjin Lianwei

In July, GTRONTEC Dongzhi signed a strategic cooperation framework agreement with Tianjin Lianwei Ethylene Engineering Company to jointly develop a scenario-based health management solution for reciprocating compressor units. This initiative achieves multiple industry-first applications, including the replacement of imported software for hydrogen reciprocating compressors in the petrochemical industry and breakthroughs in core algorithms, contributing to the goals of carbon peak and carbon neutrality!

To this end, various sectors across the country are extensively and deeply carrying out carbon peak actions, supporting key industries and enterprises in taking the lead. GTRONTEC Dongzhi is deeply involved in this effort, leveraging mature industrial internet products and technologies to help various industries, especially the petrochemical sector, reduce carbon emissions and optimize energy structures.

Tianjin Lianwei Ethylene Engineering Co., Ltd. is one of the first restructured units of the Sinopec Group. It is a specialized股份制 company with independent legal personality, engaged in the maintenance and repair of petroleum and chemical installations, offering services such as the operation, maintenance, and repair of electrical, instrumentation, and mechanical equipment in the petrochemical industry, as well as the installation and maintenance of industrial computer control systems and network systems, related product R&D, and petrochemical engineering installation.

Beyond energy structure, with the advancement of advanced maintenance management concepts and increasing market competition, another major challenge for customers is how to leverage industrial internet information technology to develop integrated "monitoring-operation-maintenance" products and enhance diversified service capabilities.

For this project, GTRONTEC Dongzhi, based on新一代 industrial internet information technology and its proprietary feature signal extraction technology of Dongzhi EHM Equipment Health Management System (referred to as "Dongzhi EHM"), addressed the multi-dimensional scenario needs of end-users for integrated key equipment monitoring and operation management. This resulted in multiple industry-first applications, including the replacement of imported software for hydrogen reciprocating compressors in the petrochemical industry, wireless collection of valve temperature data, and breakthroughs in core algorithms. It also helped customers improve equipment efficiency and achieve energy consumption transformation.

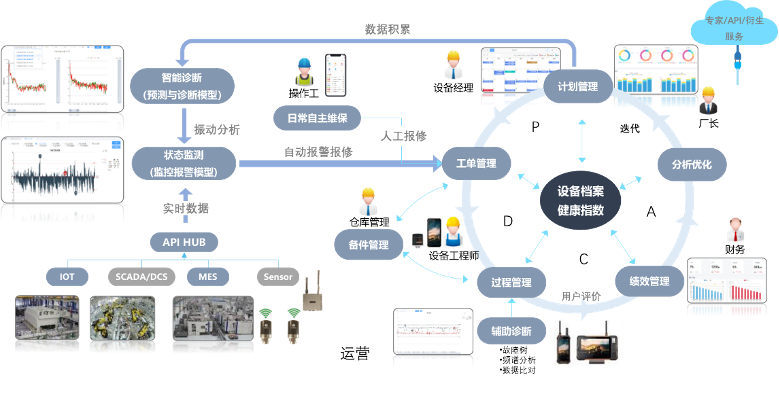

Compared to traditional condition monitoring software, Dongzhi EHM offers multi-source data collection capabilities. By integrating process control systems, instrumentation interlock protection systems, and process data such as temperature and pressure from production data management systems, it enables multi-dimensional data analysis for condition monitoring. Based on mechanism model algorithms and big data analysis modeling, it achieves full-scenario functions including early warning, diagnosis, health assessment, and decision support for condition monitoring. Additionally, the EHM health management system, driven by equipment condition data, enables closed-loop management of the entire process, including work order management, maintenance plans, dynamic spare parts management, and maintenance evaluation.

The Tianjin Lianwei Ethylene project represents another breakthrough for GTRONTEC Dongzhi in the petrochemical industry细分领域 and marks the application breakthrough of GTRONTEC Dongzhi's EHM health management product for reciprocating compressor units in the petrochemical industry.

Under the national goals of carbon peak and carbon neutrality, GTRONTEC Dongzhi will continue to deepen its intelligent products to support enterprises in achieving "green" development. "When many people work together, even a heavy task becomes light!"