A Manufacturing Revolution is Slowly Unfolding in the Semiconductor Field

Since TI engineer Jack Kilby invented the integrated circuit in 1958, this new industry has developed rapidly over the past decades and gradually entered various fields. Because it relates to all aspects of national economy and people's livelihood, this 'small thing' has received high global attention in recent years. Especially in recent years, due to shortage incidents and geopolitical influences, the status of semiconductors has become unprecedentedly important.

However, as the world's largest semiconductor consumer, China has not achieved a corresponding status in the semiconductor field.

Thus, vigorously developing the domestic chip industry is urgent.

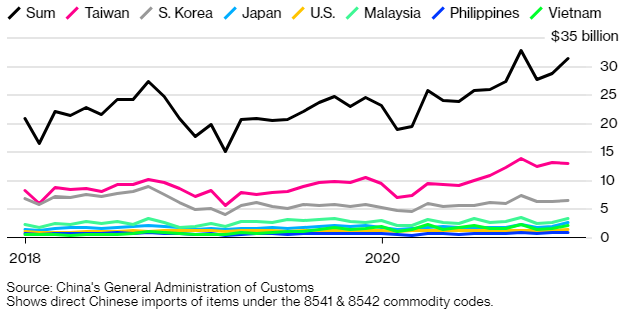

Statistics of chip imports to China from various regions (source: Bloomberg)

As a country with the world's most complete supply chain, China has layouts in IC design, production, packaging, testing, materials, and equipment, but we have not achieved corresponding IC results. This is partly due to shortcomings in the above areas. More importantly, in the view of industry experts, the lack of ability to produce stable, high-quality semiconductor products at market-optimal costs, on time, and in sufficient quantities is the key bottleneck for China's semiconductor industry to produce market-competitive products.

Complex Semiconductor Manufacturing

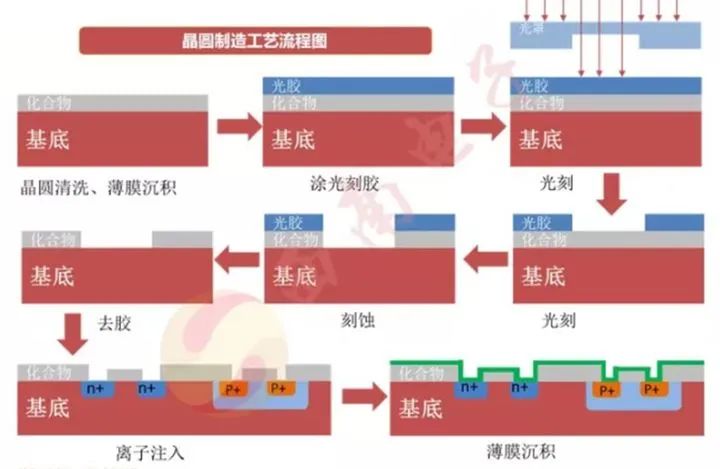

Main manufacturing steps of chips (source: Southwest Electronics)

Main manufacturing steps of chips (source: Southwest Electronics)

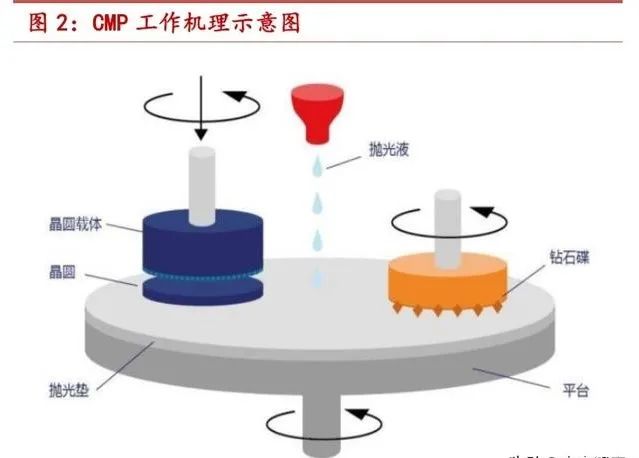

Taking CMP (Chemical Mechanical Polishing) in chip manufacturing as an example, this is a technology used to remove deposited metal or dielectric materials and flatten the wafer surface, which is a key process in wafer production. This concept seems simple, but in actual production, CMP must simultaneously meet stringent requirements for uniformity of material removal, higher production efficiency, and lower cost, greatly increasing its complexity.

CMP machine structure and working principle (source: Future Think Tank)

CMP machine structure and working principle (source: Future Think Tank)

Relevant data show that dozens of defects such as trench depth and metal film thickness fluctuations occur in the CMP process, which greatly affect product electrical parameters and yield. Among them, film thickness stability is particularly important for the process.

Statistics show that CMP film thickness abnormalities and defects are related to various complex factors involved in the production process, including previous processes, equipment and process parameters of this process, and even material batches. With such a massive number of influencing and interrelated factors, engineers cannot well单独 analyze the actual influencing factors, improve yield, and ensure process stability and product quality using past tools and technologies.

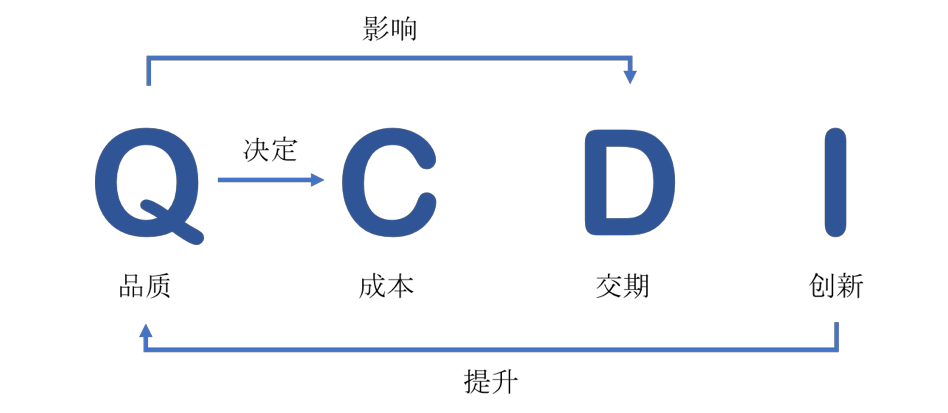

Yield determines competitiveness

Yield determines competitiveness

Industry experts also point out that improving production yield will directly affect and optimize the production cycle, greatly reduce production costs, thereby strengthening the market competitiveness of products and enterprises. As semiconductor manufacturing processes and technologies become increasingly complex, the manufacturing process becomes more challenging, and yield improvement becomes extremely difficult. From relevant analysis, the main reasons for this difficulty are as follows:

1. Complex process steps. Products require processing through hundreds of complex steps, each requiring almost 100% yield; otherwise, the multiplicative relationship of yields quickly destroys overall yield.

2. Highly re-entrant processes. Products need to repeatedly enter the same process for processing multiple times, each time facing variation phenomena such as gradual shift or sudden drift; the root cause of quality issues lies in high variation.

3. Difficulty in real-time quality control. Yield faults can only be detected through sampling inspection. The lag of inspection itself and the probabilistic nature of sampling seriously affect the real-time acquisition of quality data, thereby affecting real-time quality control.

Limited by technology, this has been a problem plaguing the industry for many years, but in recent years, practitioners seem to have found a new answer—that is, the industrial internet.

Industrial Internet Helps Upgrade

GTRONTEC Technology Co., Ltd., a leading high-end manufacturing industrial internet company in China, points out that closely integrating industrial internet technologies, models, etc., with the production practices, industry characteristics, and knowledge experience of various industries can solve production pain points and bring real value to production. Among them, semiconductor manufacturing is one direction they focus on.

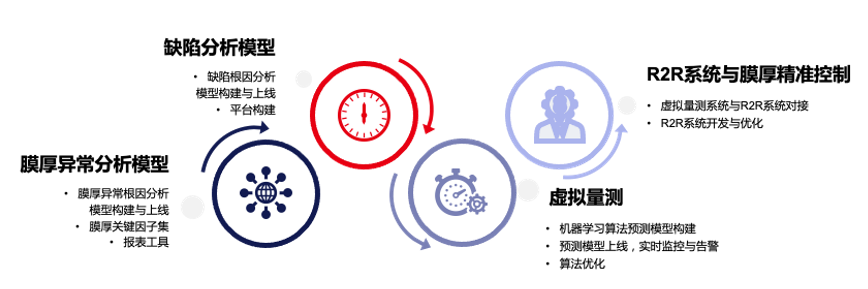

Still taking CMP in semiconductor manufacturing as an example. Actually, to control production variation and improve semiconductor manufacturing yield, three points need to be achieved: First, comprehensive data needs to be obtained during the production process to monitor the production environment; second, full inspection quality data还需要 be obtained to monitor the variability of production quality parameters; third, real-time engineering process feedback and control能 be achieved to ensure that the fluctuations of the production system are in a stable optimal controlled state is also key.

In other words, it is to form a quality control closed loop of comprehensive real-time data analysis and engineering process control (EPC), by continuously adjusting and optimizing operating variables to compensate for the interference and impact of production variation on the process, maintaining the stability of output product quality.

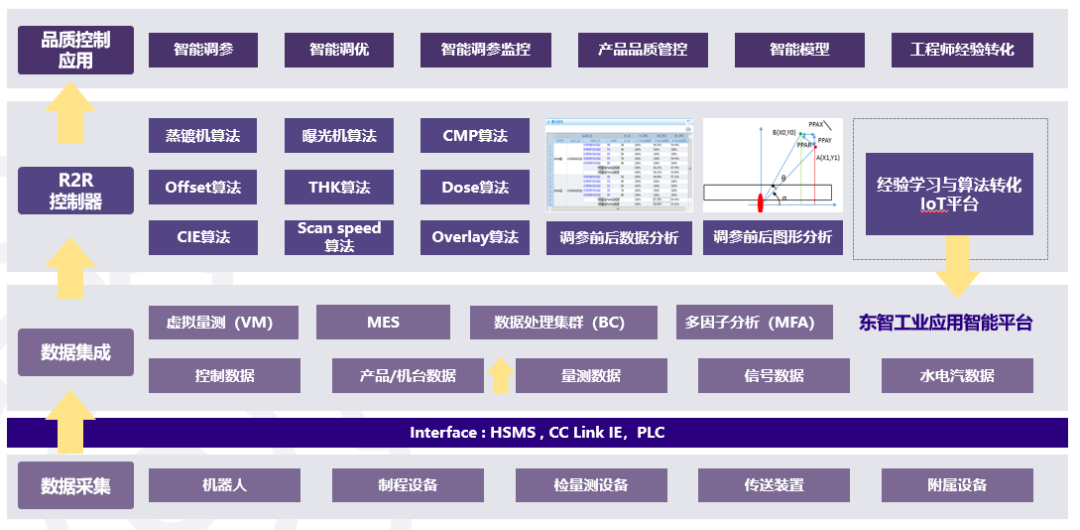

"These three points constitute the core architecture of the industrial internet-based R2R run-to-run control solution (detailed architecture见下图)." GTRONTEC emphasized.

GTRONTEC continued to point out that the industrial internet can widely connect various semiconductor production elements, comprehensively obtain, store, manage, and analyze real-time data related to quality, solving the problem of missing data; while virtual metrology (VM) uses artificial intelligence algorithms to learn from a large amount of production quality-related data, continuously correcting and optimizing using sampling inspection data, obtaining a predictive model of the relationship between key quality indicators and process data, thereby predicting production quality and providing full inspection 'measurement' data in a digital way 'in real time'.

As for the R2R intelligent controller, it combines the advantages of statistical process control (SPC) and advanced process control (APC). Driven by comprehensive production element data and virtual metrology full inspection data, it incorporates feedback and feedforward mechanisms into statistical process control, optimizing and adjusting process parameters on production equipment based on production environment data, measurement data, and production data from previous batches, thereby eliminating or reducing the impact of production variation phenomena such as sudden drift and gradual shift of environment, equipment, and process parameters on semiconductor product quality, reducing operational errors, and achieving the goal of improving product quality.

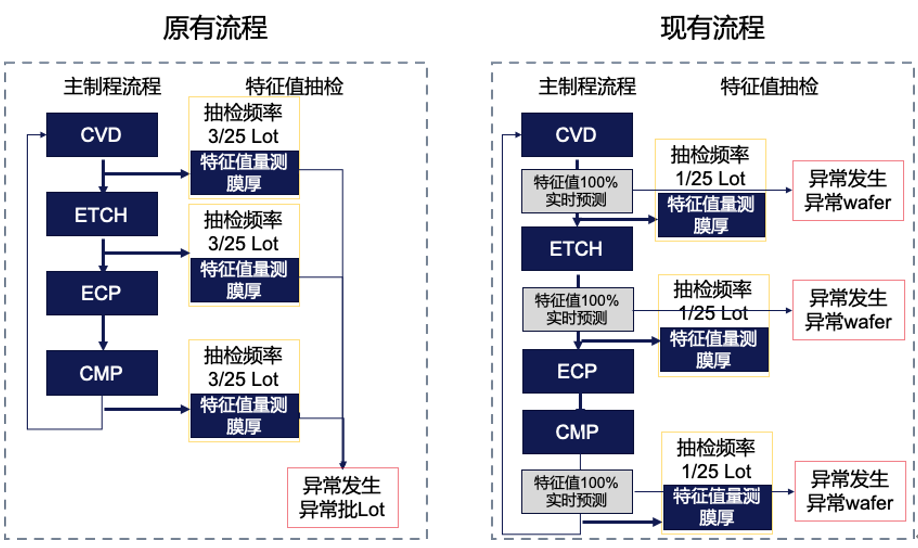

Specific implementation plan and steps of R2R at a domestic wafer fab

Specific implementation plan and steps of R2R at a domestic wafer fab

According to GTRONTEC, they deployed their R2R solution at a domestic wafer fab, resulting in significant improvements in customer capacity and yield, while labor costs also decreased. At the same time, with the help of their data analysis algorithms and other capabilities, GTRONTEC helped customer staff improve data analysis capabilities and speed, and also helped the enterprise cultivate multi-factor analysts. These are rare assets for the customer in the future.

R2R system implementation process reengineering at a wafer fab

R2R system implementation process reengineering at a wafer fab

GTRONTEC used the effect before and after the Cu CMP process transformation of a certain product at this wafer fab as an example to illustrate the value of their solution.

They pointed out that after their system went online, 100% OOS (out of specification) abnormal samples can find the root cause through the system for parameter adjustment, and over 75% OOC (out of control) abnormal samples can find the root cause for parameter adjustment. The film thickness prediction accuracy is >98%, the average prediction error is <1%, and the model activation effectiveness ratio is 100%. Additionally, the product achieved automatic monitoring and correction of process equipment parameters by the system. By importing process data and measurement data into the R2R calculation model, the accuracy of R2R system calculations improved by over 10%, with significant performance optimization.

GTRONTEC booth at SEMICON China 2021 located in Hall N2 No. 2703

GTRONTEC booth at SEMICON China 2021 located in Hall N2 No. 2703

At the end of 2020, GTRONTEC participated in the second China Industrial Internet Competition with its semiconductor manufacturing R2R extreme quality control solution, standing out among 1457 participating teams and winning the national second prize. Achieving such excellent performance in the semiconductor manufacturing field is closely related to GTRONTEC's accumulation in the industrial IoT field over the past few years.

Empowering More Industries with Intelligent Platform

With outstanding strength, GTRONTEC has served many leading customers in the past three years, with the Dongzhi Industrial Application Intelligent Platform as its main tool.

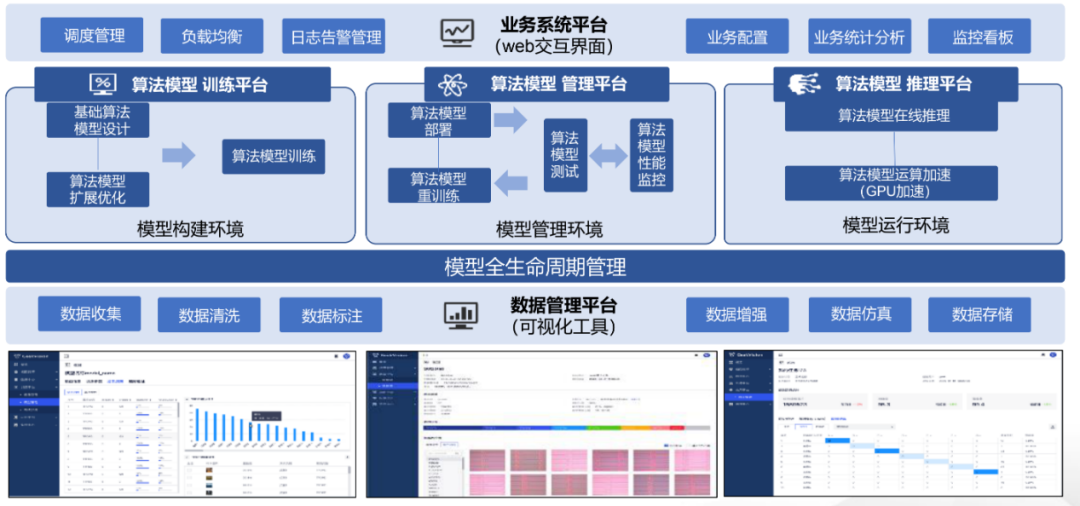

Architecture diagram of Dongzhi Industrial Application Intelligent Platform

Architecture diagram of Dongzhi Industrial Application Intelligent Platform

The Dongzhi Industrial Application Intelligent Platform is dedicated to providing one-stop digital manufacturing solutions for data collection, data analysis, and intelligent applications for industrial field equipment. As an innovative enabling middle platform, the Dongzhi Industrial Application Intelligent Platform can call upon four core capability platforms: IoT platform, big data platform, AI platform, and technology middle platform, helping users quickly build rich industrial applications such as equipment health management, predictive maintenance, product quality analysis and improvement, AI visual inspection, and supply chain optimization.

From the materials provided by GTRONTEC, we can see that the Dongzhi IoT platform provides one-stop data collection, device对接, data storage, data management, data display, and data analysis functions, helping enterprises achieve real-time monitoring and maintenance of equipment inside and outside the factory, reduce equipment abnormal downtime, and improve factory operational efficiency.

Dongzhi IoT platform architecture

Dongzhi IoT platform architecture

The Dongzhi big data platform is a comprehensive data capability platform that can汇入 data from the backend and business middle platform, perform data sharing and integration, organization and processing, modeling and analysis, management and governance, and service applications, unifying data standard calibers and providing services via API. This not only makes data business-oriented, avoids the emergence of 'data silos', improves business efficiency, and better drives business development and innovation. At the same time, it can accelerate the value transformation from data to data assets, changing the decision-making model from 'experience-driven' to 'analysis-driven'.

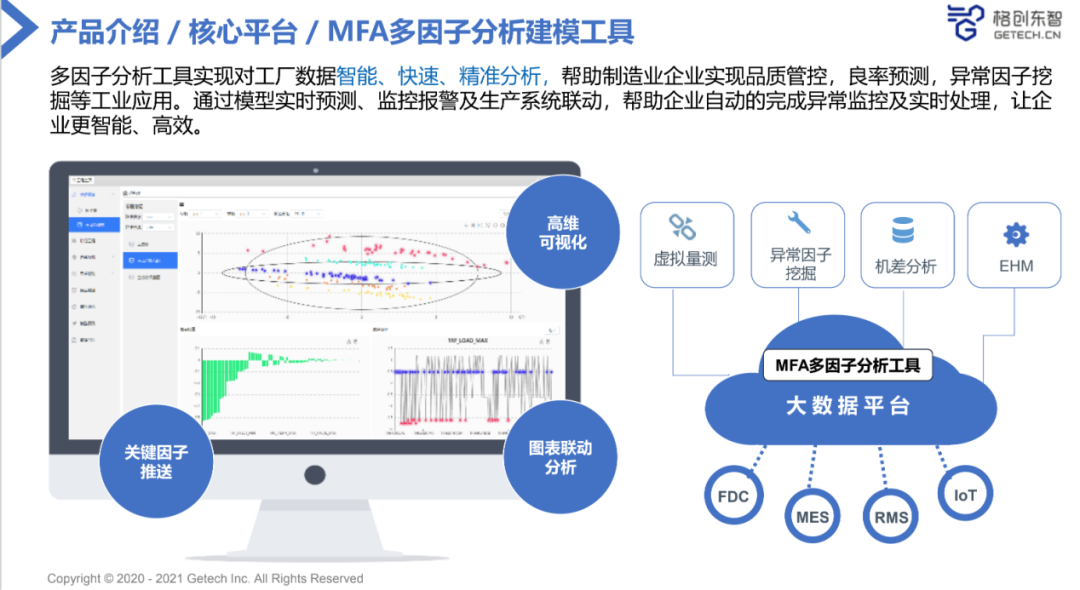

The Dongzhi MFA multi-factor analysis modeling tool can quickly determine the root cause of production abnormalities, with significant application effects at a certain LCD panel factory: reducing the defective unit of LCD panels from batches to single pieces. The annual economic benefits of a single factory increased by millions.

Dongzhi big data platform

Dongzhi big data platform

The Dongzhi AI platform is a big data application platform based on deep learning algorithms, covering three major modules: model training platform, resource scheduling platform, and inference platform, achieving autonomous learning of algorithm models, customer-oriented application management, and reasonable allocation of hardware resources.

The visual defect recognition system developed based on the Dongzhi AI platform improves AI recognition speed by 5-10 times, accuracy from human eye's 85% to over 90%; replaces over 50% of manpower, achieving annual economic benefits of over ten million.

Dongzhi AI platform

Dongzhi AI platform

Based on the above platforms and middle platforms, GTRONTEC can provide services such as quality process optimization, equipment health management, energy management optimization, machine vision inspection, production operation optimization, and supply chain optimization. Taking equipment health management as an example, a certain machining enterprise subscribed to different functional suites of Dongzhi Equipment Health Management (EHM), meeting its full-scenario needs for equipment management, achieving equipment intelligent diagnosis, maintenance, predictive maintenance, remote maintenance, and spare parts prediction. By deploying Dongzhi EHM, the enterprise's production output increased by 3%-5%, equipment abnormal downtime reduced by 10%-20%, and equipment maintenance costs reduced by 10%-15%.

Based on the continuously accumulated ITxOT integration capabilities in practice, GTRONTEC also provides customers with digital factory consulting and intelligent equipment integration support.

Localization Replacement of Industrial Software

For GTRONTEC, if they continue in the above manner, their goal of becoming the 'Google' of the industrial internet界 and polishing industrial software that makes Chinese people proud will be within reach.