How to Build a Smart Factory? This 'Tool' Is Indispensable

As the core system of smart manufacturing, MES has now become a 'must-have' for enterprise digital applications. Even under the severe impact of the COVID-19 pandemic last year, China's MES market still achieved positive growth.

Based on the Dongzhi Industrial Application Intelligent Platform, GTRONTEC has developed the Dongzhi MES, which is universally applicable to manufacturing enterprises, and the upgraded Dongzhi MOM system, safeguarding intelligent production for enterprises.

01

'Unique' Dongzhi MES

In addition to these 'basic operations,' Dongzhi MES also offers additional 'BUFF' enhancements:

No.1 Flexible and Configurable

GTRONTEC MES is developed based on the unified Dongzhi Industrial Application Intelligent Platform, adopting a microservices architecture that supports flexible configuration according to customer needs.

No.2 High Integration

Integrating internal and external project implementation experience and standardized integration interfaces, it supports effective integration with upstream and downstream systems, reducing integration risks.

No.3 Low Development Costs

For customized customer requirements, low-code development technology is used to quickly complete secondary function development, effectively reducing development costs.

No.4 High Product Maturity

Adopting an internal validation and external promotion model, product upgrades and updates are validated across TCL's 23 manufacturing bases with different production modes, significantly improving product maturity.

02

Dongzhi MES Packaged Upgrade—Dongzhi MOM

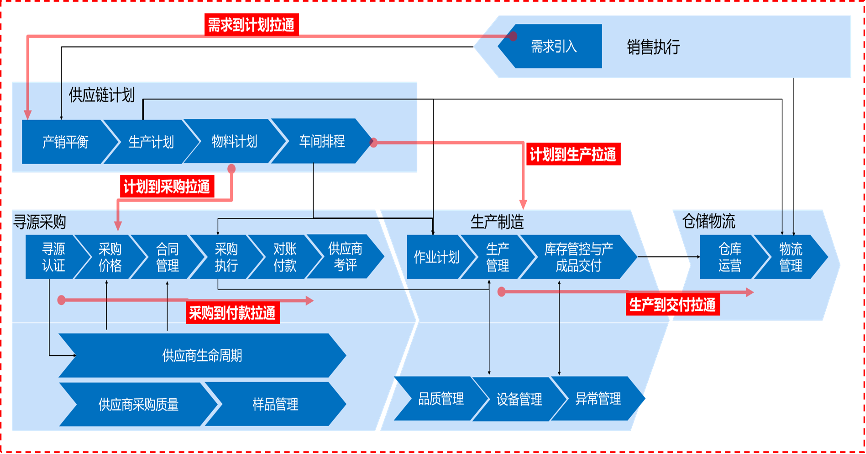

To address this issue, GTRONTEC, from a supply chain perspective, created an end-to-end integrated application solution for manufacturing—the Dongzhi MOM system.

The Dongzhi MOM system merges or splits traditional SRM (Supplier Relationship Management), WMS (Warehouse Management System), and MES, enabling free configuration based on business scenarios. It fundamentally solves problems such as poor scalability, weak process reconfigurability, and long project implementation cycles of traditional MES platforms.

03

Benchmark Case

In 2020, GTRONTEC and WuGang Weika reached a strategic cooperation agreement to jointly build a modern digital factory.

Previously, the customer's production process suffered from weak IT infrastructure, reliance on manual paper records, relatively complex scheduling, and poor responsiveness to changes. GTRONTEC focused on building MES, WMS, and IoT business applications, connecting the chain from customer orders to logistics and delivery. It achieved automatic evaluation of order delivery times, full transparency tracking, unified data management for planning, equipment collection, production process management, and quality processes, creating an application model with end-to-end interoperability in production, supply, and sales execution information and vertical end-to-end integration of the decision chain.

Digitalized management, forming data assets: achieving centralized collection and storage of control system basic data, integrated and shared with MES; reshaping production methods and management models: various new production methods to quickly respond to market demands and expand business models; real-time online monitoring of people, machines, materials, methods, and environment; integrated production control to improve production efficiency: optimizing production processes, improving production techniques, and accelerating production speed; scientific and rational scheduling to enhance equipment utilization and improve production execution accuracy; reducing production costs: minimizing material waste, easing warehouse pressure; lowering product defect rates and reducing quality anomaly losses; reducing labor demands and cutting labor costs; warning/reducing abnormal downtime: real-time warning of equipment failures through real-time data collection and rule engine configuration; predicting equipment lifespan through multi-factor analysis.

04

Conclusion

As an application on the Dongzhi Industrial Application Intelligent Platform, Dongzhi MES adopts a microservices architecture. It can be used independently, upgraded to Dongzhi MOM, or seamlessly integrated with other Dongzhi application systems (such as Equipment Health Management EHM), ensuring product scalability. It provides customized services for the digital needs of different enterprises, solving production task execution challenges with one click, and achieving a comprehensive 'transparent factory'!