Strength Certification|GTRONTEC Selected as 'Top 20 Industrial IoT Typical Case Collection'

In 2021, the IoT industry entered a new development cycle, embracing the wave of industrial transformation and upgrading.

Based on the general principles of "typicality, leadership, innovation, and replicability," the Shenzhen IoT Industry Association, research-oriented media in the IoT field—Sharp Angle AIoTRay, and IoT Media selected typical practical cases from eight major areas of AIoT and jointly initiated the '2021 Top 20 Industrial IoT Typical Case Collection' selection activity. GTRONTEC was selected for its strength with the Dongzhi Equipment Health Management System (EHM)!

TCL-incubated GTRONTEC has developed into a leading industrial internet platform company in China, providing customers with new-generation information technology products and smart manufacturing solutions centered on the industrial internet platform. Leveraging TCL's 40 years of manufacturing experience and large group digital transformation practical experience, it has accumulated core technical capabilities for multi-scenario manufacturing, building modular and replicable platform systems to drive the transformation and upgrading of China's manufacturing industry from point to surface. The Equipment Health Management System (EHM) based on the industrial internet is defined by GTRONTEC as one of the application directions that need to be broken through first.

Dongzhi EHM

Integrated Management of Equipment "From Birth to Death"

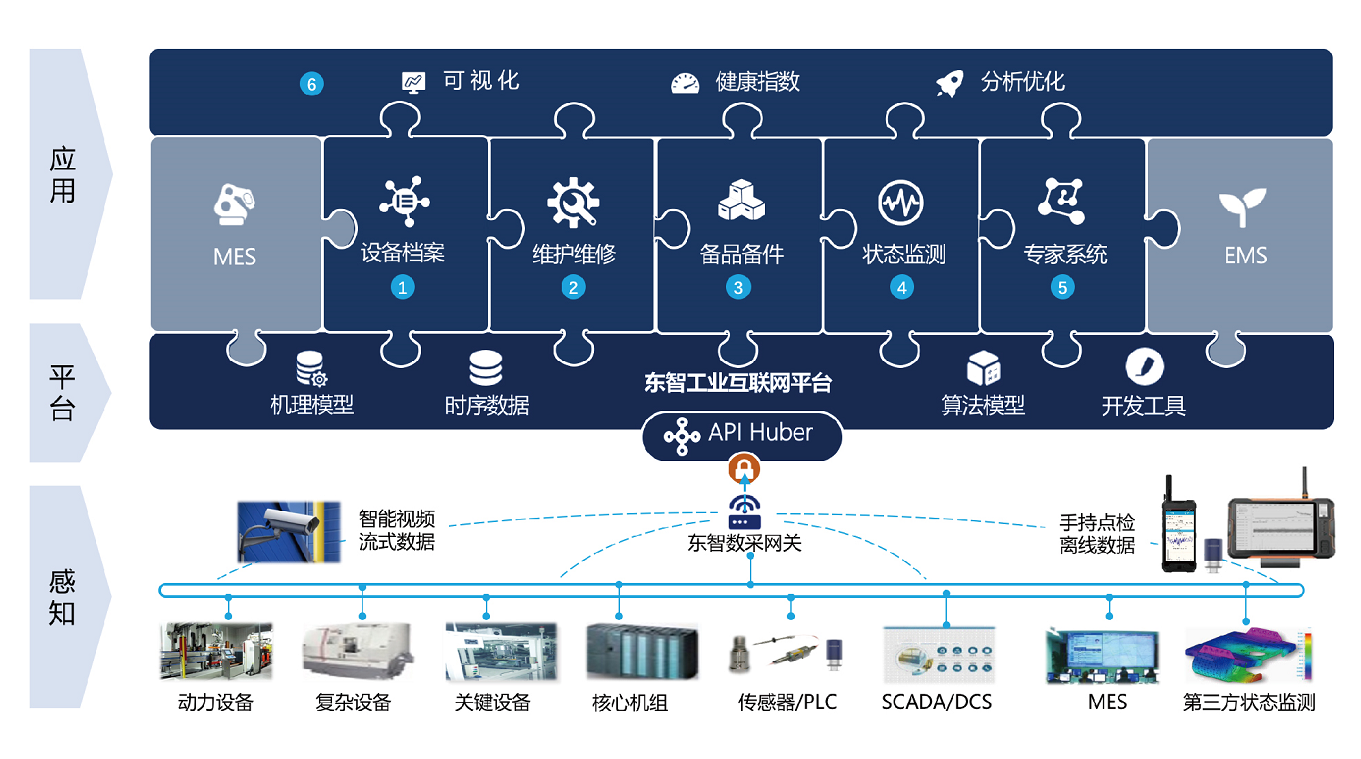

Therefore, the Dongzhi Equipment Health Management System EHM (hereinafter referred to as Dongzhi EHM) came into being. Dongzhi EHM is a scientific management tool designed to ensure and improve equipment stability and safety, thereby reducing enterprise operating costs; its main process addresses the complete management and maintenance of industrial equipment throughout all stages of its lifecycle; its main functions include operation monitoring, fault diagnosis, health assessment and maintenance, maintenance records, spare parts tracing, etc.

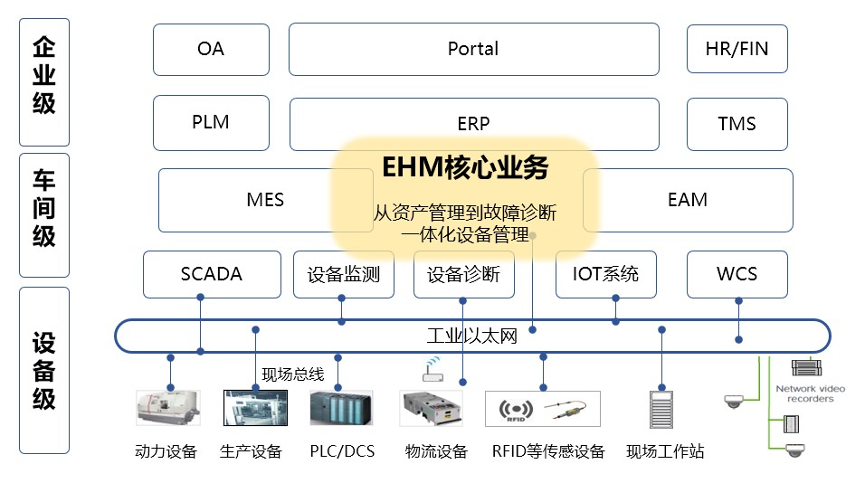

As the core system of a new generation of equipment management, Dongzhi EHM can uniformly store and model manage data from various underlying control and diagnostic systems, IoT, and other related equipment, and interconnect with top-level equipment master data such as ERP, MES, and EAM. If an enterprise lacks EAM, or equipment management modules in ERP or MES, EHM can serve as the main system for enterprise equipment management, replacing the equipment management of systems like EAM and MES.

*Figure 1: Position of Dongzhi EHM in Enterprise Digital Architecture

*Figure 2: Overall Architecture of Dongzhi EHM

Empowering Digital Transformation

Helping Enterprises Find the Optimal Balance in Equipment Maintenance

From the perspective of customer value, Dongzhi EHM focuses on practicality and implementation. In just three years, it has been applied in over 100 benchmark customers across more than ten industries, including power, metallurgy, mining, petrochemicals, paper printing, subways, semiconductors, machining, and automotive heavy industry, accumulating extensive practical experience. On average, it improves customer equipment overall efficiency by over 10% while reducing operation and maintenance management costs by over 20%, helping enterprises achieve the essence of equipment management: finding the optimal balance in equipment operation and maintenance.

Dongzhi EHM can also achieve consistent monitoring of equipment process parameters, realizing integrated equipment management, one-map equipment monitoring, one-table job management, and other effects. It reverses traditional misconceptions and concepts such as emphasizing production over maintenance, automation over digitization, helping enterprises truly achieve Equipment Management 4.0.

In the petrochemical industry, Tianjin Lianwei, an engineering company providing inspection and maintenance for large petrochemical enterprises, saw Dongzhi EHM upgrade sensors and data acquisition systems for 100% of its core compressor units, achieving second-level data transmission, calculation, display, and storage, increasing the company's equipment digitization rate by over 25%. In Shandong Energy, Dongzhi EHM's fault intelligent diagnosis and inspection modules work together,配合东智设备健康管理手持多功能移动端, improving the company's inspection efficiency by 22% and overall equipment efficiency by 15%.

In the semiconductor industry, addressing the unplanned downtime of CVD (Chemical Vapor Deposition) PUMPS at TCL CSOT, a leading LCD panel manufacturer, the GTRONTEC team completed the deployment of Dongzhi EHM's rotating equipment condition monitoring and fault intelligent diagnosis module within one day after on-site research. PUMP equipment data was uploaded to Dongzhi EHM's proprietary cloud in real-time at a sampling frequency of 50,000 Hz per second, ensuring that subtle changes in vibration signals could be identified and analyzed by the Dongzhi EHM expert system. Over more than a month of operation, the big data algorithms built into the Dongzhi EHM system effectively identified PUMP degradation trends and intelligent fault diagnosis, with significant results. Dongzhi EHM's comprehensive performance is more than twice optimized compared to similar foreign products.

Additionally, Dongzhi EHM's condition monitoring and predictive maintenance modules have been successfully deployed at a satellite launch tower in Hainan, achieving digital health management for the launch platform and providing a domestic solution for large precision structural health detection that can compete with foreign products.

As the wave of smart manufacturing continues to advance, the Dongzhi EHM system will also continue to set sail. In the future, GTRONTEC will join hands with more excellent enterprises and partners for strategic cooperation, promoting high-quality development in manufacturing and ushering in a new era of digital industry.