Highlights of the High-Tech Lithium Battery Industry Summit | A Deep Dive into the 'Construction History' of Smart Factories, Full of Insights!

On June 15, Dr. Li Nan, General Manager of GTRONTEC Dongzhi's New Energy Business Unit, was invited to attend the 15th High-Tech Lithium Battery Industry Summit 2022, delivering a keynote speech titled 'Activating Production Capacity, Improving Quality, Data-Driven Green Smart Factory Construction,' sharing how GTRONTEC Dongzhi continuously refines from four dimensions—production, equipment, quality, and energy—to build smart factories that achieve goals such as ultimate cost efficiency, yield rate, efficiency, and energy savings.

Below is the full text of Dr. Li Nan's speech for your reading:

Good afternoon, everyone. I am very happy to share experiences on smart factory and smart manufacturing construction here. GTRONTEC Dongzhi was incubated by TCL and has extensive experience in building smart and benchmark factories in industries such as semiconductors, new energy, and 3C electronics. Today, we want to share insights from a factory perspective on how to implement smart manufacturing and smart factory construction. Click for free expert services.

01

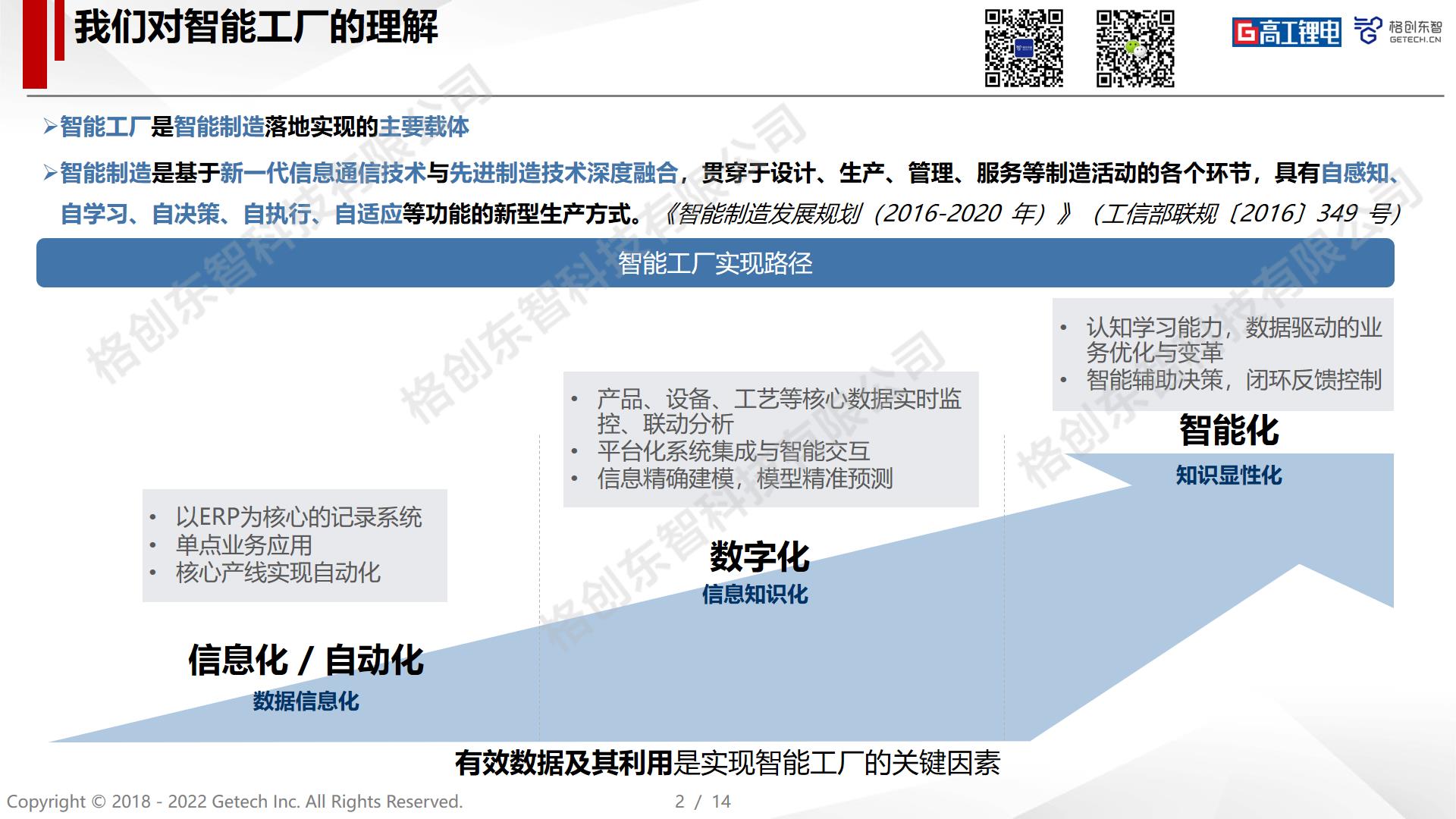

Our Understanding of Smart Factories

Regarding smart factories, we often hear customers ask: Why, despite having systems like MES, WMS, SRM, QMS, and fully automated production lines, does the factory's production capacity not increase? Why does the yield rate not improve? Why are delivery cycles and fulfillment rates still very low?

I believe many manufacturing companies face similar issues. The reason is simple: most companies' smart factory efforts focus on the first and second stages. However, the most critical aspect of a smart factory is leveraging effective data to drive smooth operations, which few companies truly prioritize or achieve.

02

Challenges in Building Smart Factories in the Lithium Battery Industry

We have visited many lithium battery companies, including upstream material suppliers and cell/Pack factories, and summarized their pain points around the core metrics of D, Q, C, E for smart factories.

For example, while planned production capacity in the lithium battery industry is high, actual output is often low. This is due to poor equipment utilization and lack of systematic maintenance and management.

Quality control is another major pain point. Batteries require high consistency in capacitance, and any deviation in process, equipment, or environment can lead to abnormalities. However, many factories lack comprehensive process control and system support, resulting in subpar yield rates.

Cost control is also a challenge. Building a 20GW factory requires thousands of employees, and subsequent factories need similar numbers. This raises the question: if a company builds 10 or 20 bases, will it need 30,000 or 40,000 employees? Reducing labor while expanding capacity is a key concern.

Energy consumption is critical. The EU has strict carbon emission requirements for battery exports, but lithium battery factories are energy-intensive with high carbon emissions. There is significant room for optimization, and proactive measures are needed to reduce energy use.

03

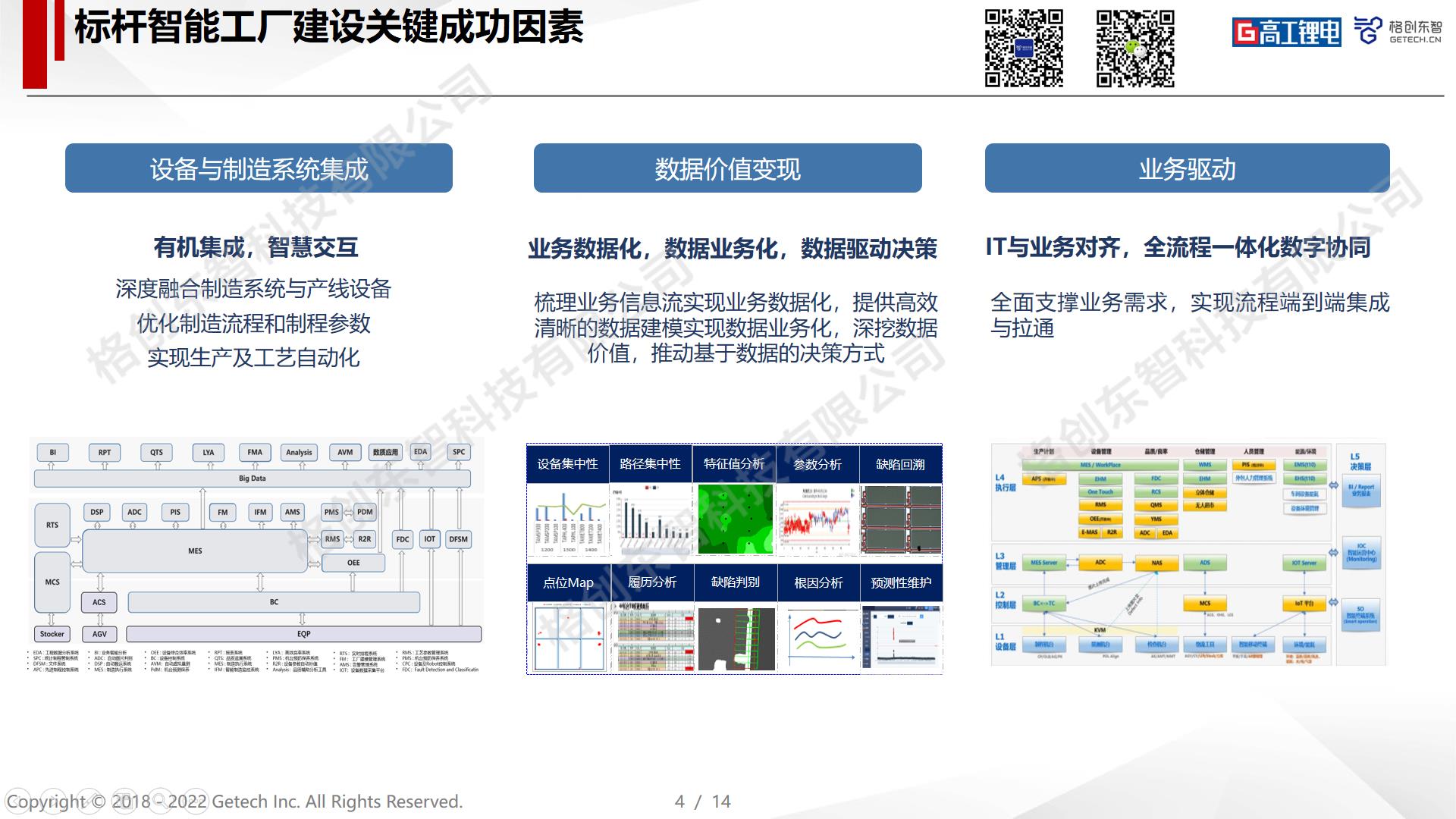

Key Success Factors for Benchmark Smart Factories

So, how can these issues be resolved? Before diving into methods, let's share the key success factors we've observed in benchmark smart factories.

First, promote extreme integration of equipment and manufacturing systems. Beyond production line automation, achieve automation in production control, process optimization, and equipment adjustments.

Second, emphasize data value mining and integration with management. Truly capture and apply experienced workers' knowledge to drive closed-loop management.

Third, ensure business-driven initiatives. While IT often led信息化 efforts in the past, successful信息化 must be driven by business units to ensure end-to-end process integration and maximize business value.

04

Refining Production, Equipment, Quality, and Energy

Let's start with production. The lithium battery industry is highly automated, making equipment utilization crucial. Reducing manual intervention and automating production and process adjustments are key.

Benchmark factories use equipment automation systems for functions like error-proofing, parameter validation, production control, and automatic program distribution, ensuring seamless integration between production systems and equipment while minimizing manual intervention and ensuring product consistency.

In equipment management, benchmark smart factories implement full lifecycle management from procurement, using sensors and algorithms for monitoring and analysis to ensure high OEE and faster production ramp-up.

Low equipment utilization is a core reason for capacity gaps in the lithium battery industry. We need to push equipment suppliers for improvements while building in-house capabilities for equipment control and optimization.

Two examples: predictive maintenance for rotating equipment common in lithium battery factories, using mechanism and data models to quickly identify component abnormalities; and knowledge management for equipment repair, using technologies like knowledge graphs to digitize and disseminate repair knowledge, helping engineers quickly troubleshoot.

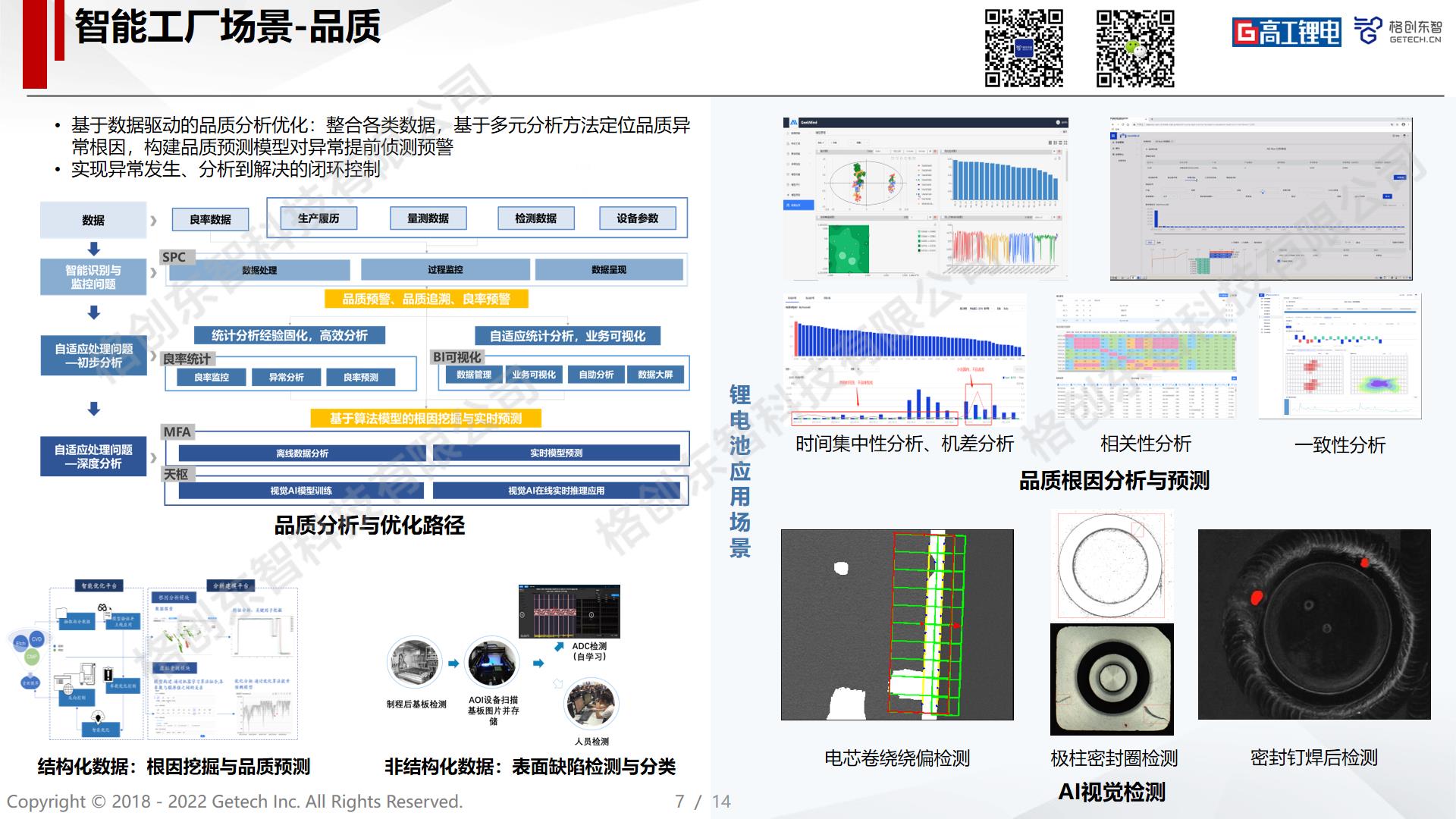

In quality, benchmark factories use comprehensive systems like SPC, QMS, and YMS to track anomalies, identify root causes, and leverage machine learning and big data for yield prediction models, helping engineers find optimal process parameters.

Applications in lithium battery factories include machine variance analysis, surface density analysis, coating parameter optimization, and defect detection. Comprehensive quality control ensures consistency and reduces manufacturing costs.

Finally, in energy, lighthouse factories prioritize energy and carbon management, using extensive monitoring and analysis to reduce energy costs by 2-5% annually, saving millions. They are also building carbon management systems toward carbon neutrality.

The summit highlighted the importance of energy/carbon for the lithium battery industry. Energy costs are significant, often reaching hundreds of millions annually. Many companies are unprepared for future carbon restrictions, so building energy and carbon management capabilities and implementing节能减排 measures is advised.

05

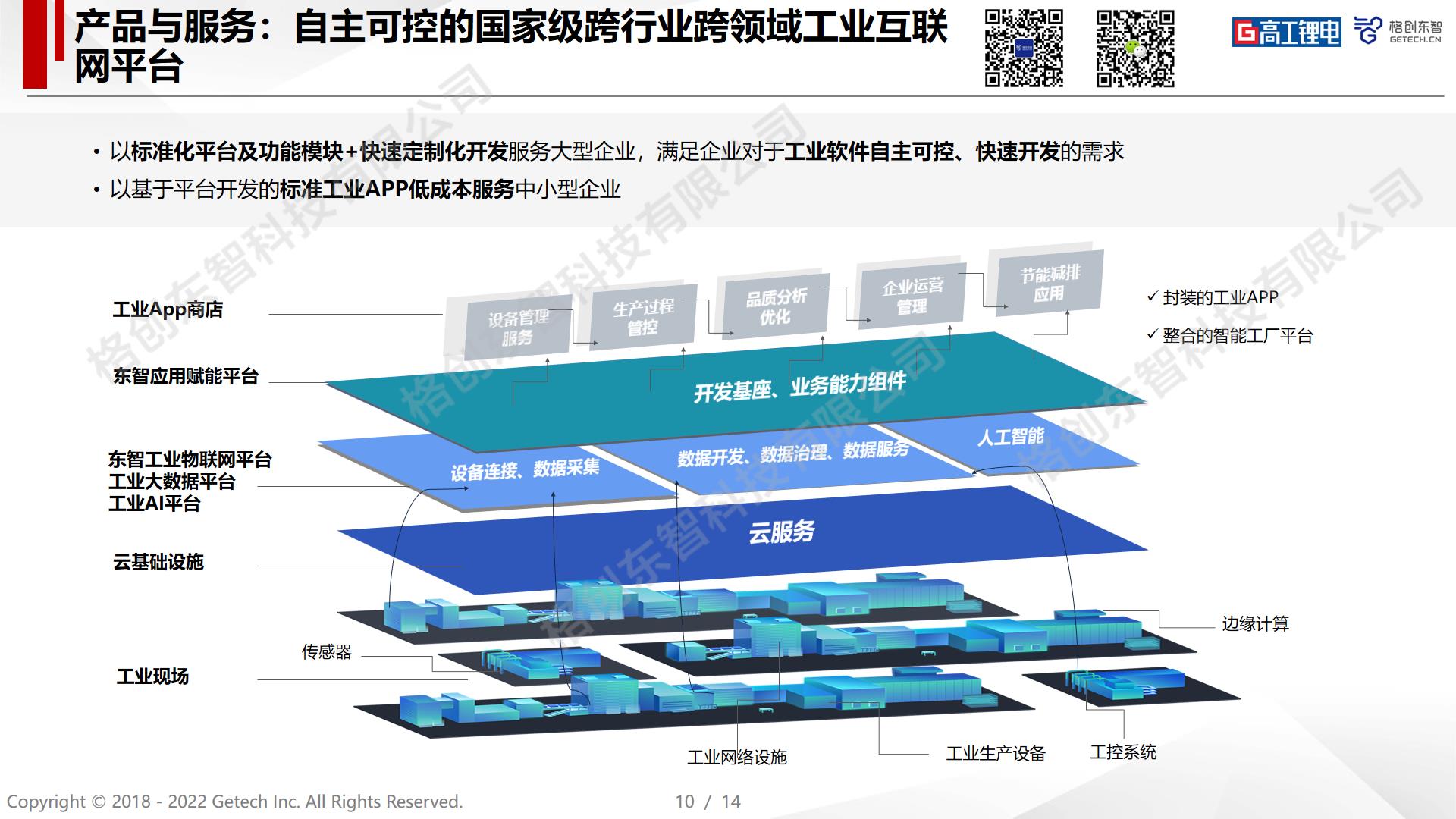

Industrial Internet Empowering Smart Factories

Lastly, an introduction to GTRONTEC Dongzhi. Incubated by TCL, we have over 1,400 employees serving clients in semiconductors, new energy, 3C, and automotive industries. Our benchmark factory cases are built on our industrial internet platform, covering data collection, IoT, big data, and applications like equipment health management, production management, quality analysis, and energy savings, providing integrated solutions for industry-level smart factories.

Our self-developed Dongzhi platform was recently certified by the Ministry of Industry and Information Technology as a 'Cross-Industry Cross-Domain Industrial Internet Platform,' joining the 'national team.'

In the new energy sector, we serve lithium battery factories and upstream clients like cathode/anode material and electrolyte producers. We also collaborate with equipment manufacturers to embed our software systems, enhancing equipment value. We aim to leverage GTRONTEC's experience in industrial internet and smart manufacturing to help more lithium battery companies build their own benchmark lighthouse factories. Thank you!

For more product information, scan the QR code below.