GTRONTEC Participates in Co-authoring the World's First AI Model Development Management Standard

Recently, the Cloud and Big Data Research Institute of China Academy of Information and Communications Technology released the world's first AI model development management standard—"Artificial Intelligence Development and Operations Integration (Model/MLOps) Capability Maturity Model Part 1: Development Management." GTRONTEC, along with over 30 leading industry companies such as Huawei, Baidu, JD.com, SenseTime, and Fourth Paradigm, co-authored this standard. As an industrial internet platform company participating in the compilation, this demonstrates GTRONTEC's outstanding technical strength in the integration of AI development and operations in industrial scenarios.

Development Management Standard Co-authoring Units

With the full explosion of AI engineering applications, companies undergoing intelligent transformation are shifting their focus from complete and easy-to-use tools and platform systems to the development, operation, and management of AI assets such as data, algorithms, and models. MLOps and ModelOps technologies are regarded as the best path to achieve large-scale AI applications and have garnered widespread attention from the industry and AI technology users.

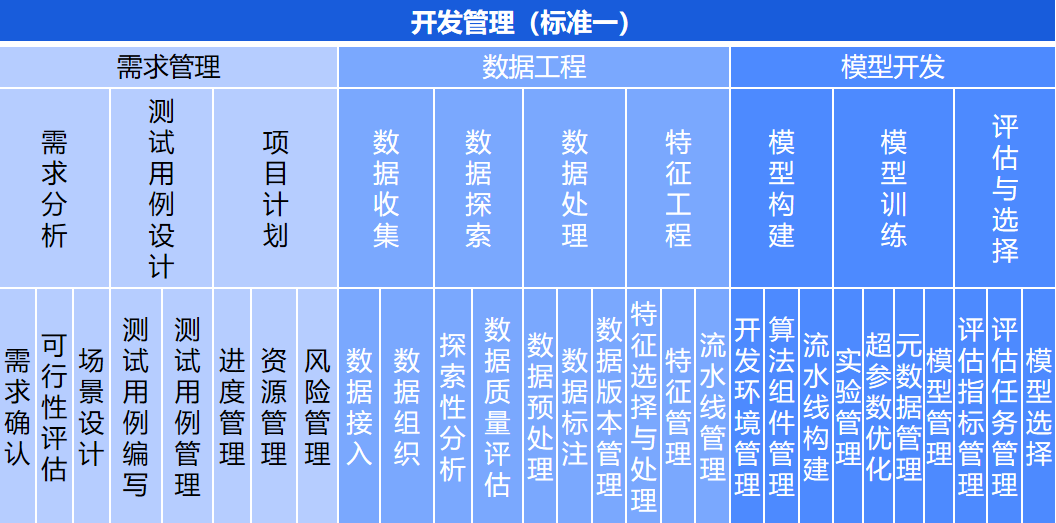

As the first standard in the "Artificial Intelligence Development and Operations Integration (Model/MLOps) Capability Maturity Model" series, this standard fills the gap in development management standards for machine learning projects both domestically and internationally. The standard addresses three capability sub-domains: requirement management, data engineering, and model development, including 10 capability items and 28 sub-items. It proposes five levels of capability requirements for the machine learning development management process: Basic, Professional, Excellent, Outstanding, and Leading.

Standard Part 1 "Development Management" Structure

As an industrial internet platform company participating in the compilation of this standard, GTRONTEC has been committed to the application and practice of new-generation technologies such as artificial intelligence, big data, edge computing, and digital twins in the manufacturing industry since its establishment, empowering front-line factory production, quality optimization, and equipment maintenance.

GTRONTEC has accumulated deep technical capabilities and practical experience in the three capability sub-domains covered by the standard: requirement management, data engineering, and model development. Among these, GTRONTEC's strength in model development is industry-leading, with capabilities in complex model construction and management, industrial application development, and transaction capabilities, having沉淀 nearly 30,000 industrial models.

GTRONTEC excels in applying AI technology in the industrial sector with advanced technology, rich scenarios, and significant results. Its self-developed Tianshu AI Visual Inspection System covers all areas of industrial production and manufacturing, from incoming material identification and warehousing, incoming material inspection, dynamic monitoring of personnel operations, visually guided intelligent assembly operations, quality inspection, quality analysis, to process traceability before and after shipment. It enhances the intelligence level of production lines, reduces manual workload, improves personnel safety, ensures quality stability, accelerates production speed, and builds fully intelligent production lines.

GTRONTEC's Tianshu AI Visual Inspection System features an industry-leading integrated technology architecture of "sensing, storage, computing, and cognition," efficiently achieving autonomous learning of algorithm models, customer-oriented application management, and rational scheduling of hardware resources. It has launched industry-specific products for the semiconductor, new energy photovoltaic, and SMT industries: SEMI ADC, SE ADC, and SMT AIR. These have delivered significant quality optimization and efficiency improvements for many leading companies in semiconductors, pan-semiconductors, new energy photovoltaics, 3C electronics, and other fields.

○ GTRONTEC's SEMI ADC all-in-one machine for the semiconductor industry can complete defect judgment in real-time and automatically handle processes according to the workflow, reducing abnormal interception time by 1-2 hours, shortening the production cycle of inspection stations by 60%, and achieving annual人力效益 of over ten million per production line.

○ For the new energy photovoltaic industry, NE ADC, and for the SMT industry, SMT AIR, enable centralized intelligent re-judgment of inspection data across the entire factory, analyze production capacity and quality status, increase inspection直通率, help factories improve yield while saving over 85% of production line technician manpower, and achieve annual production cost reduction benefits of millions per factory.

Scan the QR code below to access the "Standard"