Semiconductor Industry Observation Report | Semiconductor Industry Welcomes Golden Decade, Who Can Help Domestic Wafer Fabs Seize the Opportunity?

Driven by global consumer market demand, the chip industry continues to maintain strong growth momentum. Recently, the authoritative industry organization World Semiconductor Trade Statistics (WSTS) predicts that after a strong growth of 26.2% in 2021, the global semiconductor market will achieve double-digit growth again in 2022 (16.3%) to $646 billion. A McKinsey research report 'Leading Semiconductor Industry Strategy' points out that with the increasing demand for chips from autonomous driving, vehicle electrification, and artificial intelligence, the entire industry is ushering in a 'golden decade for semiconductors'.

Over the past 15 years, China's chip industry has grown rapidly, with output value increasing nearly 14 times, with an average annual compound growth rate of 19.2%, far higher than the global growth rate of 4.5%. However, the proportion of chip imports, especially high-end chips, still relies heavily on foreign sources. For China's semiconductor industry to seize the golden decade, it must not only accelerate breakthroughs in chip design, semiconductor materials, and production processes but also upgrade and iterate wafer fab production systems to seize the initiative—as domestic wafer fabs continue to expand and increase capacity, the 'life-level software' CIM system that supports their entire production process has become key to building competitive advantages for wafer fabs and the entire industry chain.

”*Excerpt from an in-depth report by the well-known semiconductor industry media 'Semiconductor Industry Observation'—'Semiconductor Industry Welcomes Golden Decade, Who Can Help Domestic Wafer Fabs Seize the Opportunity?'.

Full text of the report:

#01

Wafer Fabs Challenge Advanced Processes

Cannot Do Without 'Strongest Brain' Support

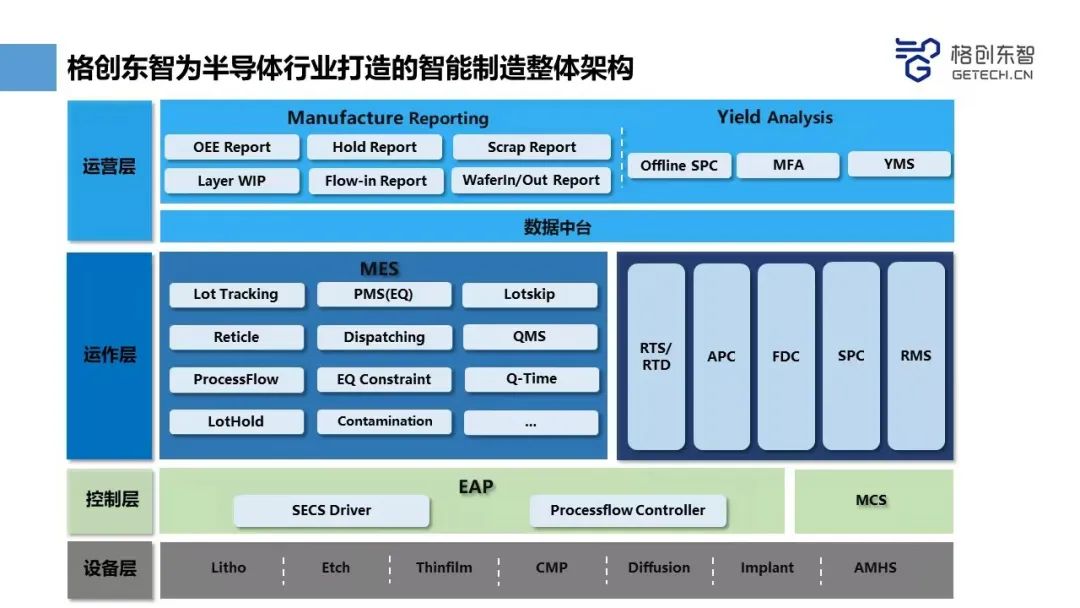

The CIM system is known as the 'central brain' of wafer fab production, integrating key systems such as Manufacturing Execution System (MES), Equipment Automation Program (EAP), Statistical Process Control (SPC), Advanced Process Control (APC), Fault Detection and Classification (FDC), and Yield Management System (YMS). It runs through critical links in chip production, including production execution, operations, and control, and manages equipment and factory personnel. As the industry has developed, the complexity of chip production processes has grown exponentially, and processes have lengthened, driving wafer fabs to continuously pursue technological breakthroughs and innovations in advanced processes. This requires the CIM system to keep upgrading and iterating to meet and support the industry's rapid growth.

Based on current process technologies, a single chip production requires at least hundreds or even thousands of processes and hundreds of pieces of equipment. Each device can generate terabytes of massive production data in just 24 hours of operation. This demands that the production system must handle and process vast amounts of complex data and provide production control and support for increasingly stringent wafer manufacturing needs. Therefore, the CIM system first needs high stability and high concurrency processing capabilities. More importantly, system development throughout the entire production process requires rich semiconductor know-how.

'As wafer fabs face increasing process complexity, they encounter huge challenges in production management and process control, which places higher demands on the intelligence of CIM systems and the refinement of system functions. The value of semiconductor CIM systems is more prominent. For example, GTRONTEC builds a new generation of Industry 4.0 smart factories for the semiconductor industry. Through intelligent software, it makes equipment smarter and process control more precise, breaks through traditional automation bottlenecks, helps mature process lines increase capacity and reduce production time, and for advanced processes, improves product performance and optimizes production and process design,' said Xiao Changbao, Chief Architect of GTRONTEC and Head of Semiconductor Software Product R&D, to Semiconductor Industry Observation.

GTRONTEC has been selected and certified by the Ministry of Industry and Information Technology as a '2022 Cross-Industry Cross-Domain Industrial Internet Platform'. As a dual-cross-industry platform originating from China's semiconductor manufacturing industry, GTRONTEC is not only skilled in industrial software and system R&D for尖端制造业 like semiconductors but also one of the few domestic head manufacturers providing full-stack factory integration services. Services range from whole-plant and multi-plant digital consulting and solution design,信息化落地实施交付及后续运维, to building semiconductor industry factory production systems based on a new 'production-analysis-prediction' perspective. Its self-developed CIM has industry-leading core technical strength and empowerment capabilities.

#02

Not Just Software: Whole-Plant Capability

Is the Foundation for Successful CIM Implementation

For wafer fabs, the successful implementation of the crucial CIM system depends not only on the software's own technical strength and maturity but also on the CIM manufacturer's rich and comprehensive overall planning design and implementation experience. Especially today, as industry upstream and downstream production cooperation becomes closer and new-generation CIM includes dozens of complex systems, the 'stitched monster' model that focuses only on MES or a few subsystem point needs and gradually adds or wedges in other systems or even external systems is increasingly revealing its core flaws of high functional redundancy in commercial suites and large system integration workloads.

Therefore, whole-plant capability—whether the service provider has technologically advanced, stable self-developed full-stack solutions and knows how to perfectly connect and integrate dozens of functionally different yet interrelated systems through forward-looking planning and precise implementation in whole-plant, multi-plant, or even industry chain upstream and downstream collaboration—has become the foundation for successful CIM implementation in wafer fabs in the next decade.

As one of the few domestic manufacturers with self-developed products implemented in the upstream, midstream, and downstream of the industry chain, GTRONTEC's semiconductor customers cover semiconductor materials, wafer manufacturing, packaging and testing, and semiconductor equipment. Its smart factory full-process full-stack products and solutions cover production operations, quality yield improvement, equipment health, energy consumption management, and other areas. By using new technologies to reconstruct the technical architecture of traditional software, it better supports high-concurrency, low-latency, precise, and stable business scenarios and performs excellently in integrating大量复杂、非原生系统.

Taking the whole-plant CIM project implemented in a domestic 8-inch fab as an example, GTRONTEC helped the client achieve production management, quality control, and process optimization from silicon wafers, wafer production, packaging and testing, to finished product assembly across multiple factories and workshops. This is one of the first truly implemented full-stack CIM cases covering front, middle, and back ends in China. By completing data integration across multiple businesses, processes, and systems, the client achieved full-process traceability management from raw material crystal pulling to finished product assembly, greatly optimizing management efficiency across multiple factories, with MES and EAP collaboration reaching leading levels.

Behind the full-stack products and whole-plant capability is GTRONTEC's team of over 700 and growing semiconductor professionals. Core technical experts like Xiao Changbao, Xu Lei, and Huang Shengxiang have served in leading semiconductor companies such as Intel, IBM, Applied Materials, TSMC, and Silan Micro, with average industry experience exceeding 15 years. They have rich experience in 6/8/12-inch wafer fab construction and system building for CIM, MES, EAP, APC, FDC, etc.,具备强大的研发、交付能力与规模化能力.

#03

Who Can Win the Next Decade?

Innovative Technology Application Becomes Key to Breakthrough

As more wafer fabs regard CIM as an important track to win the next decade, how to fully挖掘、发挥CIM的更大价值 in this competition has become a question that must be answered. Although it is widely believed in the industry that supporting all aspects of wafer fab production is the 'basic盘' of CIM systems, some leading manufacturers have proposed more forward-looking views.

After achieving automation and informatization, what is more valuable for wafer fabs is fully utilizing the continuously generated data resources in manufacturing, through big data analysis and intelligent prediction, to achieve full automated control and truly realize unmanned smart factories. Faced with反复的全球疫情 and increasingly severe industry chain security challenges, this is even more important for 12-inch fabs with high automation levels and growing capacity expansion challenges,' said Huang Shengxiang, a semiconductor expert at GTRONTEC. He previously worked at leading companies like TSMC and led大量半导体MES、EAP、APC、ERP等建设工作,深知数据价值对于晶圆厂特别是12寸厂的重要意义.

Taking yield and quality, core indicators besides capacity that wafer and packaging/testing fabs focus on, as an example, they are closely related to factory效益和利润率. As capacity increases and processes optimize, the factors affecting production yield become more numerous, the complexity between factors increases, and there are many hidden influencing factors that are difficult to identify and judge through traditional experience. Yield and quality issues have become major 'roadblocks' hindering semiconductor companies from achieving rapid growth. For instance, the key process CMP (Chemical Mechanical Polishing) in wafer production has high complexity, strict requirements for material removal uniformity, high production efficiency, and low cost. Relying on manual spot checks of film thickness at stations makes it difficult to analyze abnormalities in the same or different batches, not only requiring improvement in detection efficiency and accuracy but also making it hard to timely discover factors causing defects and abnormalities.

Through technological innovation, GTRONTEC has launched a rich and complete diverse product portfolio in quality, covering Yield Management System (YMS), Single Factor Monitoring System (SPC), Multi-Factor Analysis System (MFA), Visual Inspection System (ADC), and Big Data Analysis Middle Platform. The principle behind these products is to collect, process, and analyze massive structured and unstructured data sources for identification and monitoring, intelligent analysis, fully挖掘出潜藏在生产过程中的多个影响因素, timely achieve quality warning, quality traceability, yield warning, and use big data analysis results to force process optimization, avoiding unnecessary quality losses.

For the CMP detection difficulties mentioned earlier, GTRONTEC built a big data platform, fully utilized设备端和制程相关的数据参数, established multi-factor analysis models for CMP film thickness abnormalities and defect root causes, considered massive influencing factors and correlations,挖掘出工程师过去无法识别的相关影响因素; in terms of improving the timeliness of anomaly discovery, it used Virtual Metrology (VM) to建立模型高精度预测膜厚值并对异常值实时拦截, achieve 'real-time full inspection' of特征值, reduce station sampling frequency by 60%, fully发挥数据的价值, effectively reducing costs.

#04

Conclusion

In the decades of ups and downs in the semiconductor industry, there has always been a phenomenon of emphasizing hardware over software, which is also one of the important factors restricting China's wafer fabs from seizing the mid-to-high-end market. With the unexpected chip shortage in recent years and the subsequent wave of fab construction, more wafer fabs have begun to realize the importance of software related to chip production and manufacturing, using 'softness to overcome hardness' to solve difficulties and pain points in production.

Therefore, we also look forward to more domestic software manufacturers like GTRONTEC in the future,具备丰富的整厂能力和创新的技术优势, collaborate with more hardware manufacturers and manufacturing factories to escort China's semiconductor industry into the golden decade.

For more product information, please scan the QR code below