Greatech Creates China's 'Smart Brain' for Semiconductor Manufacturing

”

Since the second half of this year, the global semiconductor market has undergone drastic changes: In early August, the U.S. passed the 'CHIPS and Science Act of 2022,' strongly encouraging chip manufacturing reshoring; previously, multiple countries and regions including the EU, Japan, and South Korea have also introduced local chip support policies, striving to seize the next high ground in the semiconductor industry; recently, news emerged about restrictions on high-end GPU exports to China.

All signs indicate intensified global semiconductor regional competition. As the world's largest semiconductor consumer market, China is facing increasingly severe challenges, urgently requiring collaboration across the industry chain to break through.

Wafer manufacturing is one of the core areas in the semiconductor industry, where the CIM system is a key industrial software guiding precise factory operations—the 'central brain'—hailed as the 'EDA' of semiconductor manufacturing. Similar to EDA, the semiconductor CIM system is also a critical 'chokepoint' field, currently dominated by foreign systems in most wafer fabs.

Whether from meeting factory manufacturing needs or enhancing autonomy and controllability, domestically developed CIM software that is technologically superior, secure, stable, and autonomous has become a hot topic in the industry.

As a leading comprehensive industrial internet platform company originating from semiconductor manufacturing, Greatech focuses on breakthroughs in core industrial software technologies for semiconductor manufacturing. Leveraging deep industrial know-how, innovative technology R&D, and application in semiconductor manufacturing, it strives to build CIM systems for 8-inch and 12-inch fabs and OSAT, providing highly available, high-concurrency, secure, reliable, and continuously stable systems that support manual, semi-automatic, and fully automated factory operations.

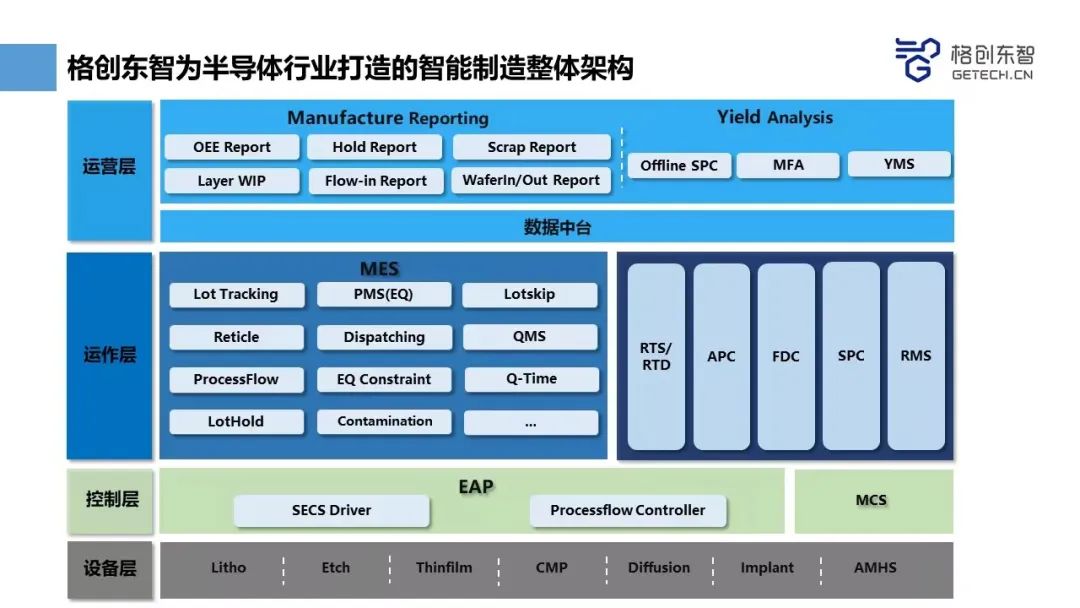

Greatech's CIM system solutions include core MES (Manufacturing Execution System), EAP (Equipment Automation), YMS (Yield Management System), SPC (Statistical Process Control), RMS (Recipe Management System), FDC (Fault Detection and Classification), MCS (Material Control System), and data middle platform, offering comprehensive one-stop semiconductor manufacturing (wafer/OSAT) solutions to help customers improve product yield, quality, and production efficiency.

Behind the powerful CIM system is Greatech's strong comprehensive strength and an experienced team of industry experts.

Additionally, the company enhances the level of smart manufacturing in semiconductor factories and tackles unknown challenges with its comprehensive full-stack solutions and continuously iterating innovative technology applications.

01 Strong Comprehensive Strength

Greatech's core technologies and capabilities are born from the smart manufacturing needs of the semiconductor industry. It has become one of the few domestic manufacturers with self-developed products implemented across the upstream, midstream, and downstream semiconductor industry chain. Its semiconductor customers cover semiconductor materials, wafer manufacturing, packaging and testing, and semiconductor equipment, enabling production management, quality control, and process optimization from silicon wafers, wafer production, packaging and testing, to finished product assembly across multiple factories and workshops.

02 Experienced Industry Experts

Currently, Greatech has over 1,500 employees globally, with a semiconductor industry team exceeding 700 people, including more than 120 semiconductor professionals and experts. It possesses strong R&D, delivery, and scaling capabilities. Core experts have previously worked at leading semiconductor companies such as Intel, IBM, Applied Materials, TSMC, and Silan Microelectronics. Recently, four core industry experts joined the SEMI Standards Committee, promoting industry standards while actively engaging with industry experts and partners to advance innovation and the application of new standards with digital intelligence.

03 Full-Factory Capability and Full-Stack Solutions

As one of the few leading domestic manufacturers providing full-stack factory integration services, Greatech offers services ranging from full-factory and multi-factory digital consulting and solution design, IT implementation and delivery, to subsequent maintenance. It builds semiconductor factory production systems from a new perspective of 'production-analysis-prediction' and reconstructs traditional software architectures with new technologies to better support high-concurrency, low-latency, and precise, stable business scenarios.

04 Innovative Technology, Enhancing Autonomy and Controllability

Compared to traditional semiconductor digitalization vendors, Greatech also emphasizes breakthroughs and applications of innovative technologies. It has developed and launched innovative technologies and products such as visual inspection ADC, virtual metrology VM, multi-factor analysis MFA, and big data analysis middle platform to help customers unlock data value, gain competitive advantages, and enhance autonomy and controllability.

Leveraging its four core advantages—comprehensive strength, expert team, full-factory capability and full-stack solutions, and innovative technology—Greatech has successfully served many domestic wafer fabs and OSAT factories.

In the future, it will continue to enhance its semiconductor industry service capabilities, helping more customers improve their core competitiveness through digital transformation to tackle industry challenges and seize development opportunities.

For more product information, please scan the QR code below