GeChuangDongZhi Accelerates Industrial Software SaaS Adoption, Showcases 'Killer Applications' at National SME Digital Transformation Conference

On November 9, the '2022 National SME Digital Transformation Conference,' jointly organized by the Ministry of Industry and Information Technology and the Shandong Provincial People's Government, was officially held in Jinan. GeChuangDongZhi showcased its DongZhi Industrial Application Intelligent Platform and multiple 'killer applications' at the conference.

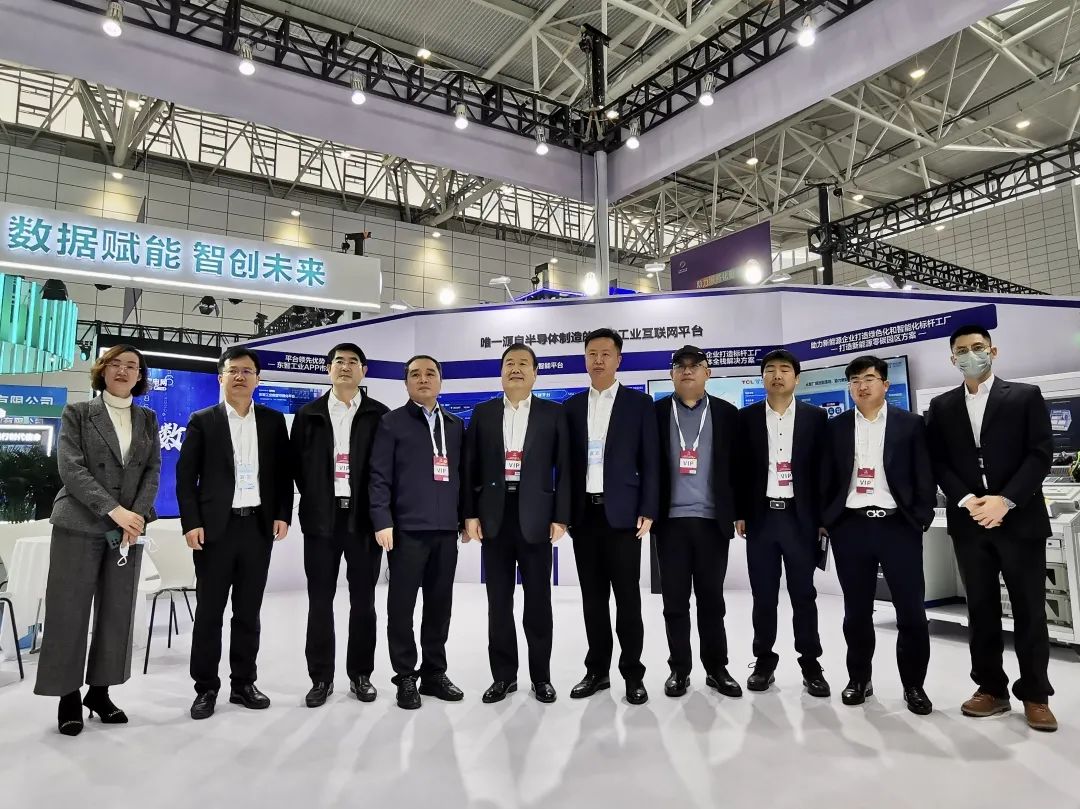

Leaders including Vice Minister of Industry and Information Technology Xu Xiaolan, Shandong Provincial Party Committee Deputy Secretary and Governor Zhou Naixiang, and Shandong Vice Governor Ling Wen inspected the conference. Deputy Director-General of the Information Technology Development Department of the Ministry of Industry and Information Technology Wang Jianwei, Deputy Director-General of the SME Bureau of the Ministry of Industry and Information Technology Wang Hailin, and Deputy Director-General of the Shandong Provincial Department of Industry and Information Technology An Wenjian visited GeChuangDongZhi's booth to provide guidance.

*Deputy Director-General of the Information Technology Development Department of the Ministry of Industry and Information Technology Wang Jianwei and other leaders visited GeChuangDongZhi's booth.

*GeChuangDongZhi technical experts provided explanations to leaders including Deputy Director-General of the SME Bureau of the Ministry of Industry and Information Technology Wang Hailin and Deputy Director-General of the Shandong Provincial Department of Industry and Information Technology An Wenjian.

#01

Digital Transformation is a Must for SMEs

For China, with its comprehensive industrial system and over 90% of enterprises being SMEs, digital transformation is a must.

However, the 'Industrial Internet Platform Empowering SME Digital Transformation Research Report' released by the China Academy of Industrial Internet shows that talent, technology, organizational, and funding issues are hindering the in-depth digital transformation of SMEs.

How to solve these common challenges and further accelerate the digital transformation of SMEs? This is a question of common concern in the industry.

Recently, the Ministry of Industry and Information Technology issued the 'SME Digital Transformation Guide,' pointing out that SME digital transformation should follow the principle of 'starting easy, progressing step by step, long-term iteration, and multi-party collaboration'; adopting application subscription-based product services to promote the digitalization of business processes such as R&D design, production manufacturing, warehousing and logistics, and marketing services, reducing one-time investment costs, and gradually advancing the digital transformation process.

#02

Accelerating Industrial Software SaaS Adoption

A 'Killer Application' for SME Digital Transformation

Based on the core capabilities of the DongZhi Industrial Application Intelligent Platform, the DongZhi Application Market has accumulated nearly 10,000 industrial APPs that can be deployed via SaaS cloud, widely empowering SMEs horizontally and lowering the threshold for their digital transformation.

Through communication with numerous SMEs, four 'killer applications' have been found to be the most popular:

1. DongZhi Quality Management System (QMS)

The importance of product quality to manufacturing enterprises is self-evident, but many manufacturing enterprises are helpless when faced with issues such as ineffective use of quality data, inconsistent quality indicators, and difficulty in statistical quality costs. The root cause is the lack of a fully functional quality management system.

The DongZhi Quality Management System (QMS) can build a one-stop quality management system for enterprises, enabling online quality monitoring, early warning, and improvement.

Currently, the DongZhi QMS is mainly used in multiple business scenarios such as quality management, laboratory management, and comprehensive quality traceability management.

Case: Through SaaS deployment, GeChuangDongZhi implemented the QMS system for a communication equipment manufacturing enterprise, achieving functions such as supplier quality management, manufacturing quality management, and quality system management, enabling full lifecycle quality management and significantly improving operational efficiency.

2. DongZhi Smart Energy and Carbon Management System

Digitalization and intelligence are important means to achieve enterprise energy management.

GeChuangDongZhi's digital energy and carbon management solution for smart factories and manufacturing parks modularly combines core products such as smart energy management (EMS), carbon management (CMS), and environmental health management (EHS), building a complete energy management value closed-loop for manufacturing, with advantages such as rapid deployment and flexible, scalable services, reducing the setup cost and threshold for SMEs.

Case: A 3C manufacturing enterprise implemented the DongZhi Smart Energy and Carbon Management module, solving issues such as dispersed factory buildings, manual meter reading, and poor data timeliness, achieving refined management of energy indicators, integrating production data, configuring different management dashboards, improving management efficiency, and enabling efficient decision-making.

3. DongZhi Equipment Health Management System (EHM)

Traditional equipment management methods are inefficient, ineffective, and uncontrollable, unable to meet the digital needs of the new generation of smart factories.

The GeChuangDongZhi Equipment Health Management System (EHM) is an integrated equipment management platform with capabilities for rapid perception, real-time monitoring, advanced warning, coordinated handling, intelligent maintenance, and diagnosis. It can integrate data from various sources such as DCS, PLC, SCADA, MES, sensors, and IoT, building multi-source data models centered on equipment for processes and working conditions, thereby establishing effective equipment health assessment models and constructing a comprehensive digital model for the entire equipment lifecycle.

Case: After implementing the DongZhi EHM, an electronics factory achieved functions such as data collection from over 300 key equipment, environmental data monitoring, and equipment health management. Through automatic warnings and assisted maintenance, maintenance response efficiency was improved, abnormal downtime was reduced by about 40%, MTTR was reduced by about 25%, and line changeover time was accelerated by about 30%.

4. DongZhi Industrial IoT Platform

Data collection on the industrial site is the first step to unlocking data value. However, due to diverse connection methods between equipment and systems and the lack of unified data standards, industrial data often cannot be effectively collected, analyzed, and utilized.

The GeChuangDongZhi Industrial IoT Platform offers advantages such as zero-code, multi-protocol support, high performance and reliability, and close alignment with industrial scenarios. It provides enterprises with real-time monitoring of equipment data centers, unified data access pipelines, improved exception feedback efficiency, and reduced visualization monitoring costs, offering an efficient, secure, and reliable industrial IoT solution.

Case: A liquid crystal panel factory needed to build a system to effectively monitor data modeling and customize equipment monitoring interfaces to address insufficient equipment operation monitoring. After implementing the DongZhi Industrial IoT Platform, the above functions were successfully achieved, with equipment modification costs reduced by 73%, alarm feedback efficiency improved by 36%, and dashboard implementation costs reduced by 87%.

In addition to the four killer applications introduced in this article, all existing products of GeChuangDongZhi can be deployed via SaaS, empowering SMEs' digital and intelligent upgrades with three major characteristics: flexibility, low burden, and high efficiency.

To learn more about product/solution details, please contact us at phone/WeChat: 400-600-2869.