Industrial Internet Helps Digital Factory Construction

Data released by foreign market research companies shows that the global smart factory market size is expected to reach $86.2 billion in 2022, and is projected to increase to $140.9 billion by 2027, with a compound annual growth rate (CAGR) of 10.3% during the period.

China's manufacturing digitalization level has significantly improved. Data from the Ministry of Industry and Information Technology shows that by the end of 2021, the numerical control rate of key processes in industrial enterprises and the penetration rate of digital R&D tools reached 55.3% and 74.7%, respectively. At the same time, many leading companies are accelerating the pace of digital factory construction.

Digital factories are the foundation and necessary path for a manufacturing powerhouse, not only a trend in future manufacturing development but also a core engine for high-quality industrial growth.

Against the backdrop of China's manufacturing upgrade and transformation, the China Smart Factory Construction and Operation Summit was recently held in Shanghai. Hundreds of product technology experts and corporate leaders from large discrete manufacturing enterprises in 3C electronics, semiconductors, new energy, automotive, and equipment manufacturing gathered to discuss market uncertainties and explore digital factory construction paths from multiple dimensions such as new technologies, products, and scenarios.

GTRONTEC was invited to share paths and cases of industrial internet driving digital factory construction at the summit, discussing with industry experts from Siemens, Honeywell, SAIC Motor, Faurecia, Inventec, and other companies on how to use emerging technologies, create new development models, and plan and build next-generation factories.

#01

Digital Factory Supports

Efficient Operation of Smart Manufacturing Systems

Yan Shaolin, Pre-sales Director of Digital Consulting at GTRONTEC, pointed out in his speech at the summit:

As China's manufacturing industry enters the digital industry cycle, more manufacturers are actively responding to and implementing China's smart manufacturing policies, using emerging technologies such as 5G, industrial internet, digital twin, and artificial intelligence to address increasingly complex challenges in product design and manufacturing, customer demand response, quality management, supply chain management, and other areas, improving factory management, production, and operational efficiency.

Figure: Yan Shaolin, Pre-sales Director of Digital Consulting at GTRONTEC, delivering a speech

Based on GTRONTEC's experience in serving over 20,000 manufacturing enterprises in China, it has keenly noticed that domestic companies' digital transformation thinking has greatly changed, shifting from focusing on traditional capabilities like technology products to building new capabilities centered on user value.

Digitalization is not just about deploying and using systems; it is a system that drives enterprises to redefine and rethink strategic goals, organizational methods, and resource allocation models.

At the same time, the connotation of digital factories is increasingly rich.

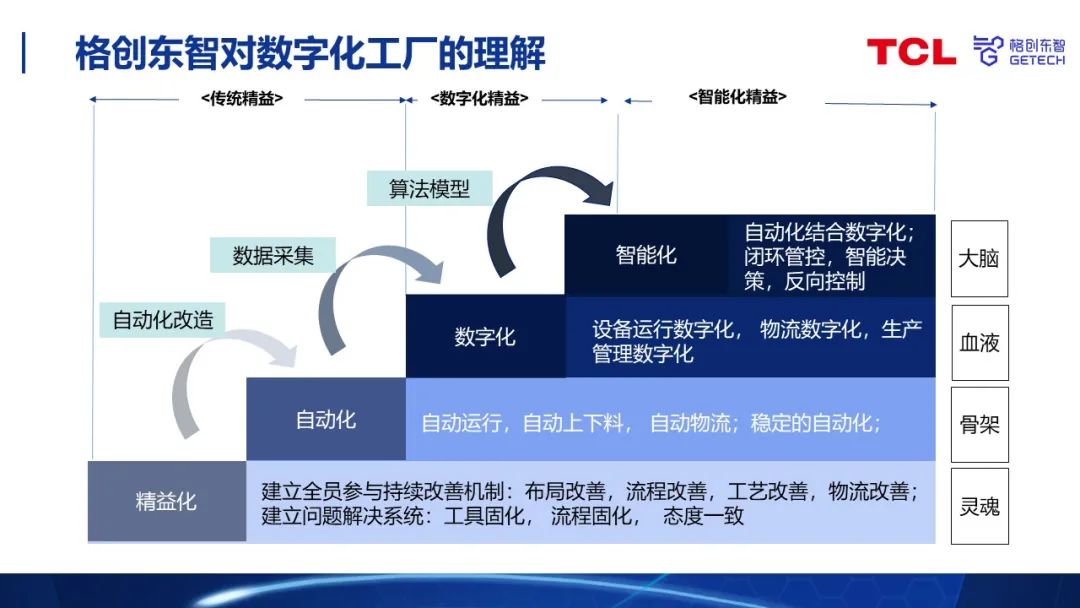

The key to the overall digital factory system is lean, automation, digitalization, and intelligence. Intelligence is the 'brain', digitalization is the 'blood', automation is the 'skeleton', and lean is the 'soul'. They permeate the entire production process, helping manufacturing transition from traditional lean to digital and intelligent lean.

Figure: GTRONTEC's understanding of digital factories

Driven by the smart manufacturing strategic vision—achieving an integrated digital lean operation system—GTRONTEC is committed to leveraging the industrial internet platform to connect end-to-end core business flows of digital factories, helping manufacturing efficiently and orderly manage production flow, product lifecycle flow, and customer value creation flow, supporting the efficient operation of smart manufacturing systems.

As the only national cross-industry platform originating from semiconductor manufacturing, GTRONTEC has served over 20细分 industries including semiconductors, new energy, smart cars, 3C electronics, home appliances, petrochemicals, and aerospace, creating benchmark digital factories and smart manufacturing solutions for many industry leaders. It offers one-stop services from top-level design to implementation delivery, with flexible service methods, experienced expert teams, and strong replicability.

Figure: GTRONTEC's digital factory top-level design process

#02

GTRONTEC Digital Factory Cases

Innovation Leads to Significant Results

Yan Shaolin pointed out in his speech that key success factors for digital factory construction include three points:

01 Equipment and Manufacturing System Integration

Is the foundation of factory digitalization and intelligence. Deep integration of manufacturing systems and production line equipment optimizes manufacturing processes and parameters, achieving production and process automation.

02 Data Value Realization

Is key to achieving intelligent factory management. Efficient and clear data modeling enables data businessization,挖掘 data value, and promotes data-based decision-making.

03 Business-Driven

Is core to determining the actual outcomes of factory digitalization and intelligence. Fully supports business needs, aligns IT with business, and enables全流程 integrated digital collaboration.

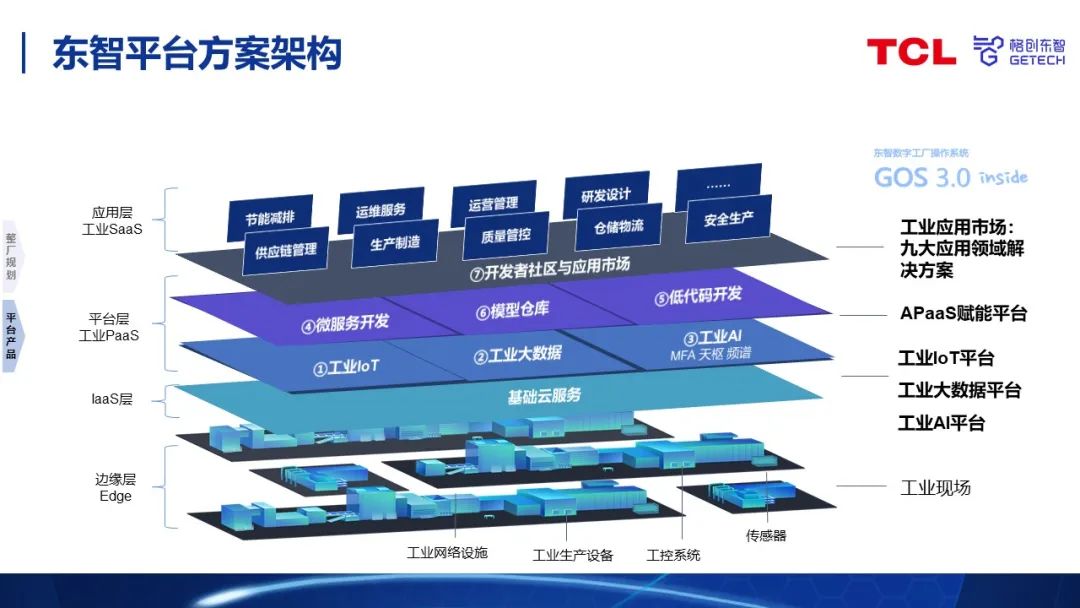

GTRONTEC's self-developed Dongzhi Industrial Application Intelligent Platform (referred to as Dongzhi Platform) is a key technical support for successfully building digital factories. It consists of GOS Industrial Operating System (3+1) + Industrial Application Ecosystem, based on three core platform capabilities: IoT, big data, and AI. It connects southbound industrial production factor resources and provides northbound industrial applications via an APaaS base for rapid development, building digital solutions covering the entire value chain.

Figure: Dongzhi Industrial Application Intelligent Platform architecture diagram

As an industrial internet platform with deep industrial底蕴, Dongzhi Platform balances the complexity of industrial scenarios and the领先性 of innovative technology. Driven by 'data + model', it excels in stability, data processing performance, complex model building, and algorithm richness, with significant cross-industry, cross-domain, and cross-regional empowerment effects.

As one of the few domestic vendors with self-developed products deployed across the industry chain's upper, middle, and lower streams, GTRONTEC's semiconductor customers cover semiconductor materials, wafer manufacturing, packaging and testing, and semiconductor equipment.

For example, in a whole-plant CIM project at a domestic 8-inch fab, GTRONTEC helped the client achieve production management, quality control, and process optimization from silicon wafers, wafer production, packaging and testing, to finished product assembly across multiple factories and workshops. It is China's first fully implemented full-stack CIM case covering front, middle, and back ends.

By integrating data from multiple businesses, processes, and systems, the client achieved end-to-end traceability management from raw material crystal pulling to finished product assembly, greatly optimizing management efficiency across multiple factories, with MES and EAP collaboration reaching leading levels.

In the new energy sector, a leading power battery company used the Dongzhi Smart Energy and Carbon Management Platform as a carrier to build a digital system for overall energy management and factory carbon measurement.

The project, built according to the client's lighthouse factory benchmark requirements, achieves unified, complete, and compliant management of energy and carbon data, implements digital energy and carbon management applications, and covers全流程 monitoring of energy and碳排放 across multiple plants. Through GTRONTEC's establishment of a standardized energy digital management system, the product's unit energy consumption significantly decreased; the company初步 established a carbon inventory and accounting system, achieving a leap in comprehensive energy and carbon management.

In the future, GTRONTEC will continue to strengthen the digital foundation and technology for manufacturing, fully leverage the value of digitalization and intelligence, partner with collaborators to enhance digital factory construction, and promote China's transition from a 'manufacturing giant' to a 'manufacturing powerhouse'.