[Industrial Empowerment Engine] Building a 'Made in China with Intelligence' Digital Factory, Autonomous and Controllable Industrial Software Supports Full-Process Management

Manufacturing is the main battlefield of digital transformation and an important support for Shanghai to build future strategic advantages. The 12th Municipal Party Congress clearly proposed to promote the integrated development of manufacturing and services, the coordinated development of industrial digitization and digital industrialization, and the interconnected development of industrial internet and consumer internet. To implement the spirit of the 12th Municipal Party Congress, accelerate the construction of a modern economic system, actively respond to the new challenges and opportunities brought by the COVID-19 pandemic, and coordinate with the release of the 'Shanghai Manufacturing Digital Transformation Implementation Plan', the 'Industrial Empowerment Engine' column is specially launched to select and showcase excellent cases of manufacturing digital transformation from the 'Industrial Empowerment Engine: Shanghai Industrial Internet Innovation Development Practice Case Collection', actively playing the leading and driving role of benchmark demonstrations, and fully promoting the digital transformation and reshaping of our city's manufacturing industry.

Under the guidance of national and local policies, China's manufacturing industry has made significant progress and achievements, moving towards high-end and high-value-added development, with significantly improved technological innovation capabilities. At the same time, the industry also faces problems such as a lack of core technologies, rapidly rising costs, and overcapacity. Manufacturing enterprises urgently need to upgrade and transform towards intelligent production and collaborative development to achieve integrated information systems, break data silos, enhance business collaboration through intelligent data analysis, improve management processes and efficiency, and build core competitiveness with digital strength. Among them, advanced manufacturing industries represented by the pan-semiconductor industry have more stringent requirements for digitization and intelligence. The pan-semiconductor industry involves large investments, extremely complex processes,极致 pursuit of quality, large data volumes with high analysis difficulty, and a series of core technologies, especially industrial software technology, that urgently need breakthroughs.

GTRONTEC (Shanghai) Industrial Intelligence Technology Co., Ltd. (hereinafter referred to as GTRONTEC) is a leading comprehensive industrial internet platform company in China, providing customers with new-generation information technology products and smart manufacturing solutions centered on the industrial internet platform. As a national cross-industry, cross-domain industrial internet platform selected by the Ministry of Industry and Information Technology, GTRONTEC was incubated and established by TCL, a globally leading high-tech manufacturing enterprise. Relying on TCL's over 40 years of manufacturing experience and large group digital transformation practice, it has沉淀 core technical capabilities for multi-scenario manufacturing, deeply cultivated digitalization in semiconductors, new energy, and other industries, and successfully assisted in the digital construction of over 20,000 enterprises across more than 20 industries, promoting the transformation and upgrading of China's manufacturing industry from point to area.

Building a 'Made in China with Intelligence' Semiconductor Digital Factory, Creating a New Model of Smart Manufacturing

A domestic semiconductor panel manufacturing enterprise served by GTRONTEC is a leader in this field, with strong capabilities integrating panel design, R&D, production, and sales. To become a globally leading smart technology company, the enterprise aims to promote business process reform, integrate智能制造 layouts across multiple locations and products, achieve full-process collaboration, enhance the overall level of smart manufacturing, and through system upgrades and the introduction of IT innovation technologies, bring sustained cost reduction and efficiency improvement benefits to the enterprise.

In 2021, the enterprise partnered with GTRONTEC to embark on a comprehensive digital transformation and upgrading journey. Through全流程、全链条的数字化升级, it promoted全方位变革 from group management and factory operation models to business processes and production operation methods, improving management efficiency and effectiveness. At the same time, the enterprise intended to vigorously promote the construction of autonomous domestic software, minimizing reliance on imported software technology to ensure that production and operations are not affected by foreign manufacturers' technology blockades.

GTRONTEC collaborated closely with the enterprise's business units to develop a comprehensive smart manufacturing strategy and implementation path, with highlights and core models as follows:

Business-driven smart factory construction, high integration of business processes and systems: The essence of digital upgrading is to solve business problems. GTRONTEC drives system function development with business processes, supporting eight core areas including operations, marketing, R&D, manufacturing, supply chain, quality, logistics, and services. Through in-depth data analysis, it enhances decision-making科学性, optimizes enterprise operations and production processes, achieves engineer business automation, and improves production efficiency and product competitiveness.

Extremely refined management, improving overall management level and efficiency: The semiconductor display panel industry has high technical barriers, with complex processes, numerous key technical points in production procedures and processes, and high difficulty. GTRONTEC conducts refined management and信息化 innovation与提升 of system operations, making data collection more comprehensive, location information more accurate,异常感知控制 more sensitive, and各个环节协同 more efficient, closely monitoring R&D, production, operations, supply chain, etc.

Autonomous and controllable industrial software, supporting secondary development: While closely integrating with business needs, GTRONTEC self-developed and built the 'central brain' of the 'Made in China with Intelligence' smart factory—the CIM (Computer Integrated Manufacturing) system architecture, and independently developed and重构 the full-chain systems supporting the smart factory's operation, ensuring safety, reliability, autonomy, and controllability. The system supports flexible technical upgrades, secondary development, and modifications; saves manpower and financial resources in equipment maintenance; and achieves high security with zero risk in information security.

Overall planning of digital factory construction, achieving full-process efficient management

1. Overall planning of the digital factory

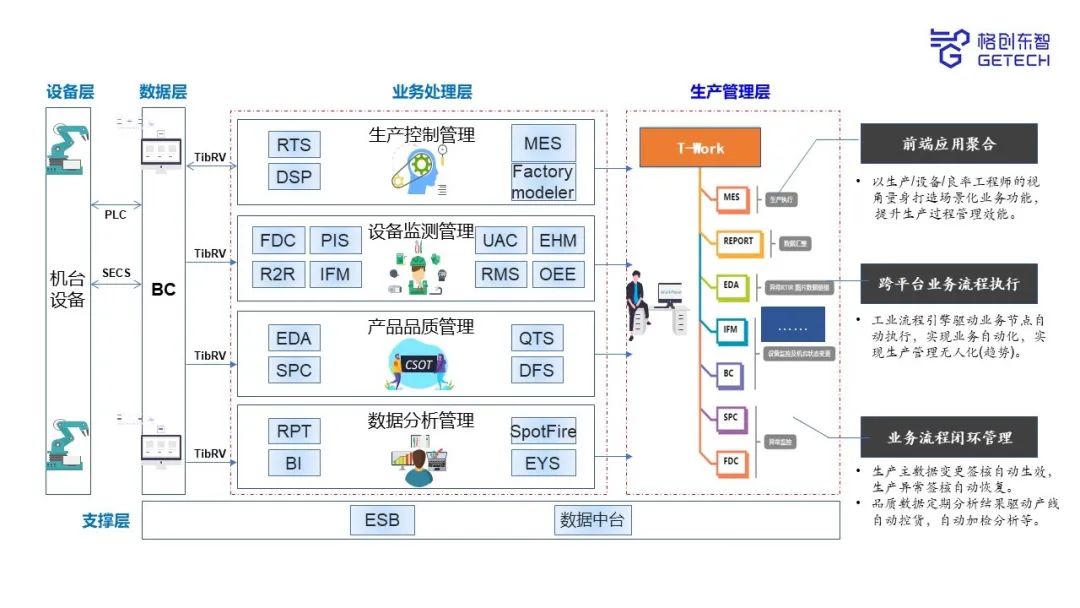

The eight major business processes of the smart factory (operations, marketing, R&D, manufacturing, supply chain, quality, logistics, services) support the factory's production and operation management. The level of the factory's production management is the level of the digital factory, and production management relies on various business systems for support. Therefore, the digital upgrade of the entire project is planned, constructed, and executed from the perspective of production management.

Based on the business characteristics of different user groups, conventional production management systems are built for fully automated production management of the factory. Qualitative and non-qualitative analysis based on various data reported by equipment is conducted to improve product quality. Short- and long-term predictions are made based on the factory's equipment status, production plans, and yield rate fluctuations to provide basis for高层决策.

2. Domestic construction of core production execution systems

Taking the customer's Suzhou factory as an example, there were originally dozens of production management systems, all using Korean system software. These systems were expensive, had slow iteration and upgrade speeds, and outdated technical frameworks. The factory's daily operation management was largely constrained by Korean technology suppliers, contradicting the customer's strategy of integrating智能制造 layouts across locations and overall enhancing digital capabilities.

Considering the above project background, it was urgent to quickly carry out the construction of domestic production systems. This system construction project involved system reconstruction based on the customer's business characteristics. The factory's entire set of CIM systems was self-developed, ensuring that after the overall project implementation, the system level reached the highest domestic and international standards.

3. China's first unified production system platform T-work

Traditional production systems are independent of each other, and users often need to switch between different applications to complete work, resulting in low efficiency and over-reliance on personal experience, which can no longer meet the作业需求 of high digitization. GTRONTEC conducted a series of technical reforms through a unified application platform to address digital challenges.

Compared to the traditional independent production system architecture, what the customer needed was a unified production operation management platform based on the production system platform. The T-work platform built by GTRONTEC helps achieve complete integration of production management systems and closed-loop management of business processes.

The T-work system is built based on the Dongzhi APaaS platform independently developed by GTRONTEC. GTRONTEC establishes data models and information interaction models on the production management system, enabling the system to have 'logical thinking'. By 'thinking' about the data uploaded by equipment, it achieves the purpose of production control. Important detailed production data recorded by the system can be provided to the reporting system for the presentation of various reports; by collecting important product异常信息 and product detection information through the system, it is provided to the quality analysis system for detailed product analysis, thereby managing quality.

4. Highlight application: Equipment management system EES

Addressing the problems of equipment data silos and high equipment management costs in traditional large factories, GTRONTEC built the equipment management system EES, including systems such as the异常感知系统 FDC, process parameter management RMS, status management EPT, etc. It can perform equipment status management, equipment parameter management, equipment parameter optimization, equipment operation status monitoring, analysis, and health prediction.

For example, the equipment异常感知系统 FDC can receive sensor Data from equipment in real time, judge whether it is normal, to assist in quality control. Through FDC, the sensor values of equipment can be monitored in real time. During workshop production, equipment uploads sensor data to the system in real time based on equipment status (generally in production status), and the system processes it to generate corresponding trend charts. These trend charts include basic information such as product ID, time, sensor value, upper and lower limits. Moreover, multiple devices or sensors can be compared and queried simultaneously, facilitating差异分析 between devices, and discovering equipment or engineering issues.

5. Highlight application: Yield management system YMS

Yield rate reflects product quality and reliability, determines chip mass production costs and enterprise profits, is one of the most important indicators measuring factory manufacturing capability, and is also the most关注 content in semiconductor manufacturing. The YMS (Yield Management System) built by GTRONTEC features hierarchical systematic analysis of yield rate, multi-dimensional异常分析, templated analysis, etc., mainly used for product defect analysis, yield monitoring, product履历分析, etc.

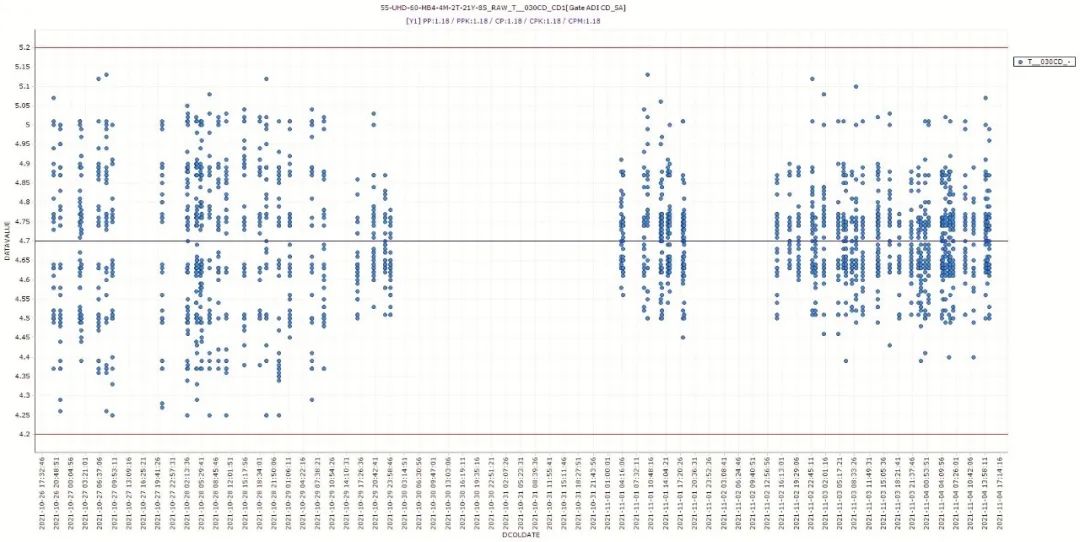

Detailed query indicators and functions include yield query (including specific defect queries), specific Glass inspection result query, Glass equipment concentration query, Dcol query (e.g., Cell Size, grinding amount), Infab Data query (e.g., grinding amount distribution), SPC query, etc.

Example 1: Through yield query, the yield of a specified product on specified equipment during a specified time period can be queried. The results can reveal abnormal yield nodes, thereby assisting in the timely discovery of yield abnormalities and defect analysis.

Example 2: When a defect abnormality occurs, by querying equipment concentration, it can be preliminarily judged whether certain equipment is the source, assisting in finding the cause of the defect.

Example 3: As shown in the figure below, Infab Data query shows the distribution of grinding amount, and sends email alerts to engineers. Engineers combine the data to judge whether there is an abnormality in the equipment status and make timely parameter adjustments or equipment adjustments.

Excellent both in social and economic benefits, building China's first autonomous and controllable semiconductor smart factory

1. Social benefits

The core production systems of high-end manufacturing in the pan-semiconductor industry (chips and panels) have long relied on foreign manufacturers. At the same time, the system architectures in this industry are relatively old and rigid, unable to adapt to the requirements of digital transformation. This digital transformation successfully replaced the entire set of foreign CIM systems with self-developed CIM systems, without降低水准 or compromising user experience, which is extremely significant in the industry and marks the advancement of domestic software towards international levels.

2. Economic benefits

Based on GTRONTEC's application platform, the information of production management systems was integrated, achieving closed-loop management of business processes and高度无人化 of production lines, laying a solid foundation for极致化工厂生产管理. At the same time, customized development of various business processes based on business characteristics彻底整合 traditional isolated systems into one set of systems, which is highly representative in the digital transformation process.

Through the digital upgrade project, the factory's production management digital level was greatly improved, breaking through capacity and quality management bottlenecks, especially outstanding in manufacturing cycle, delivery cycle, yield rate, communication, and collaboration efficiency management.

Expert recommendation

Under the background of China vigorously promoting 'digital leading' enterprises, the 'Made in China with Intelligence' digital factory built by GTRONTEC is of far-reaching significance. It features strong autonomy and controllability,精益化管理水平, comprehensive system construction, and innovative digital thinking, helping China's advanced manufacturing factories achieve safe production and enhance competitiveness to应对未知挑战. At the same time, it also opens a new示范路径 for the digital and intelligent upgrade of China's manufacturing industry, providing an important benchmark for promoting high-quality development of manufacturing and making the digital economy bigger, stronger, and better.

Source: 'Industrial Empowerment Engine: Shanghai Industrial Internet Innovation Development Practice Case Collection' Part 2 Functional System Chapter Case 27 'Assisting High-end Manufacturing Enterprises in Building Digital Factories, Achieving Closed-loop Management of Business Processes'