GTRONTEC: Full-stack Solution Creates Benchmark Smart Factory for Lithium Battery - Replication

Power battery production capacity has entered the TWh era, and how to improve efficiency, enhance quality, and reduce energy consumption has become a new challenge for the lithium battery industry.

On the one hand, power batteries are moving towards extreme manufacturing, but battery companies still face industry pain points such as large differences between actual and planned production capacity, long unplanned equipment downtime, high maintenance costs, difficulties in full-process quality traceability, and rough energy and carbon management. The smart manufacturing upgrade of power batteries is urgent.

On the other hand, the large-scale expansion of power battery production is driving the supporting scale of core raw materials to the million-ton level. Material equipment is developing towards largescale, automation, intelligence, standardization, and digitalization. The demand for smart manufacturing in the lithium battery material field is also becoming increasingly prominent.

Although lithium battery companies can currently achieve production line automation and establish preliminary information systems, overall they are still in the initial stage of smart manufacturing. In the current TWh era and as digitalization enters deep waters, existing systems are insufficient to support the high-quality development of battery companies in the later stage.

In the past, except for leading lithium battery companies, other companies were relatively rough in factory construction planning. At the same time, there were no system suppliers to guide battery companies in smart manufacturing planning from a global perspective, resulting in a low level of smart manufacturing for lithium battery companies.

However, a positive change is that lithium battery companies are paying increasing attention to smart manufacturing and are placing higher demands on equipment suppliers and MES system suppliers. But currently, the lithium battery industry lacks enterprises with macro integration capabilities that can provide systematic solutions.

As an industrial internet enterprise strategically incubated by TCL, GTRONTEC is committed to becoming a full-plant solution provider that empowers lithium battery customers with smart manufacturing upgrades. Starting from multiple dimensions such as production, equipment, quality, energy, and logistics, it helps lithium battery enterprises build benchmark smart factories and promotes the smart manufacturing upgrade of China's lithium battery industry chain.

Challenges in Power Battery Manufacturing Await Solutions

Entering a new industry cycle, the lithium battery industry faces new challenges in planning, manufacturing, design, quality control, supply chain, logistics, and other aspects. In this context, continuing with traditional manufacturing models can no longer meet the needs of the new industry stage.

For example, a lithium battery production line has over 2,500 key quality process control points, along with high-speed, high-cycle, and high-precision production requirements. Therefore, the factory must maximize equipment utilization, optimize manufacturing processes and parameters, increase output, reduce the preparation time for mass production, and make production as efficient as possible.

At the same time, production automation and process automation can reduce manual handling and intervention by process engineers and operators.

Additionally, the requirements of end applications for carbon emissions and full lifecycle management in the lithium battery production process pose significant challenges to lithium battery manufacturing.

From the perspective of quality control, numerous factors affect lithium battery quality, making production management increasingly difficult.

The performance of lithium battery products is influenced by production environment, equipment operation, incoming material batches, detection, and analysis. Traditional environmental control and detection methods can no longer meet the needs of battery companies for large-scale mass production, regionalized plant layout, and significantly improved production efficiency.

Increasingly complex production scenarios require battery companies to全面提升 production and quality control methods to ensure batch consistency of battery products.

From the perspective of supply chain management, the diversification of the supply system and the need for full-process traceability in production also challenge the supply chain management of battery companies.

As battery companies have more suppliers and larger raw material procurement volumes, the pressure on managing the raw material supply system and controlling incoming material batches is increasing.

At the same time, the traceability requirements of OEMs for power battery products extend to the upstream raw material领域, requiring battery companies to impose traceability management requirements on their suppliers in the raw material production环节, further increasing the difficulty of supply chain management for battery companies.

Overall, entering the TWh era, power battery manufacturing faces multiple challenges. Equipment upgrades and innovations in individual links by battery companies are insufficient to solve the above problems. The global optimal solution lies in电池 companies introducing smart manufacturing concepts at the initial stage of factory planning and construction and implementing them thoroughly.

Full-stack Solution Creates Benchmark Smart Factory for Lithium Battery

From the perspective of factory planning, under the背景 of large-scale capacity expansion and rapid project implementation, battery companies need to fully consider how aspects such as Layout, logistics paths, production cycles,异常处置, and automation equipment support the smart operation of the factory. Define the smart factory based on the operational needs of various levels such as factory, production line, and workstation.

For example, detailed requirements should be placed on equipment suppliers regarding interface openness and communication protocols to facilitate subsequent equipment data collection and control, supporting data applications.

At the same time, the requirements of battery companies for smart manufacturing should not be limited to the automation upgrade of single machines or single-point information construction. Instead, smart manufacturing should be planned from a global perspective, fully considering the needs of various business scenarios,梳理 the functional boundaries and interaction logic between systems, and form the enterprise's smart manufacturing construction route according to the overall plan.

To further improve production efficiency and reduce costs, power battery companies have proposed the goal of "extreme manufacturing," namely extreme cost, extreme yield, extreme capacity, and energy saving and emission reduction.

To achieve the goal of extreme manufacturing, battery companies need to achieve overall upgrades in people, machines, materials, methods, environment, and measurement, all of which need to be realized in the smart factory.

Dr. Li Nan, General Manager of GTRONTEC's New Energy Business Department, believes that smart factories are the main carrier for the implementation of smart manufacturing, and effective data and its utilization are the core of realizing smart factories.

Dr. Li Nan believes that the key factors for the successful construction of a benchmark smart factory include the following three points:

First,高度 integration of equipment and manufacturing systems. Enterprises should not only analyze and monitor the collected equipment data but also deeply integrate manufacturing systems with production line equipment, optimize manufacturing processes and parameters, achieve organic integration of production and process automation, and enable smart interaction.

Second, data value realization.梳理 business information flow to achieve business dataization, provide efficient and clear data modeling to achieve data businessization, deeply挖掘 data value, and use data to drive decision-making.

Third, business驱动. Promote the alignment of IT with business and the integration of IT with OT, achieve全流程 integrated digital collaboration, fully support business needs, and achieve end-to-end integration and拉通 of processes.

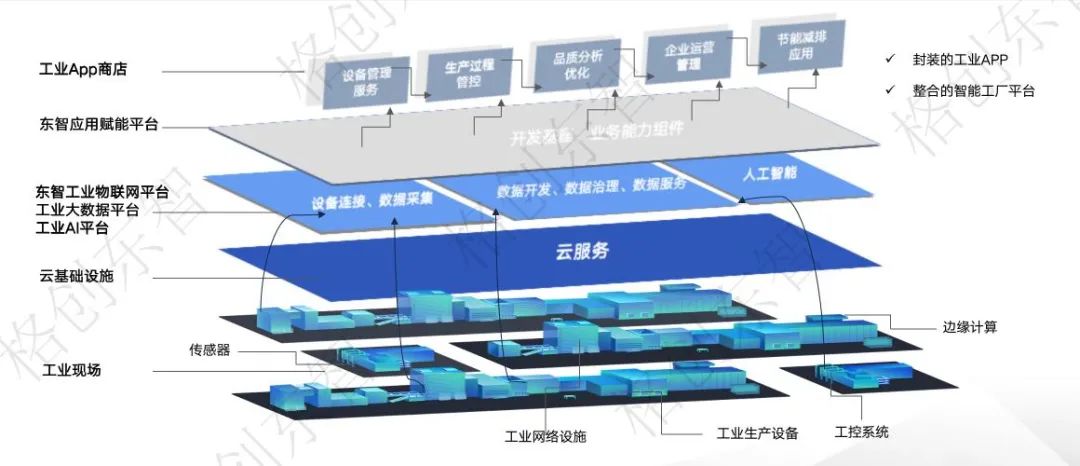

As a nationally certified cross-industry跨领域 industrial internet platform that is independently controllable, GTRONTEC meets the needs of enterprises of different sizes in various industries for smart manufacturing industrial software through standardized platforms, industrial applications, and industry solutions.

For the lithium battery industry, GTRONTEC starts from multiple scenarios such as production, equipment, quality, energy, and logistics to provide smart factory solutions for lithium battery enterprises and promote the implementation of lithium battery smart manufacturing.

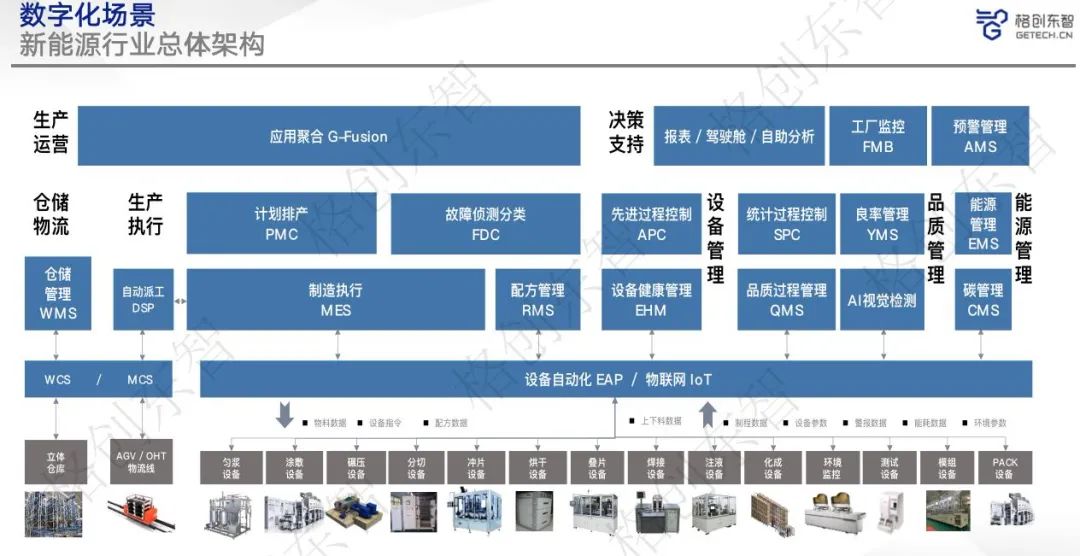

In terms of production, GTRONTEC introduces production operation management solutions into lithium battery smart factories. Through the organic integration of core products such as PMC (production planning and scheduling), RMS (recipe management), DSP (automatic dispatching), MES (manufacturing execution system), and EAP (equipment automation program), integrated production operation management can be achieved, truly realizing seamless integration and coupling of production systems and equipment.

In terms of equipment, build an integrated equipment management solution to achieve 360° comprehensive,全生命周期 management and monitoring; based on equipment status data, drive equipment health management and predictive maintenance, empowering enterprise equipment, production, process optimization, and control.

In terms of quality, conduct quality analysis and optimization based on data驱动, integrate various data, locate the root causes of quality abnormalities through multi-factor analysis methods, build quality prediction models to提前侦测 and warn of abnormalities; achieve closed-loop control from occurrence, analysis to resolution of abnormalities.

In terms of energy, use the EMS energy management platform to achieve the collection, storage, statistical analysis, energy-saving diagnosis, optimization control, and comprehensive management of energy consumption and carbon data across multiple plants; effectively solve problems such as low resource and energy utilization efficiency and difficult implementation of emission monitoring in traditional manufacturing; establish an energy and carbon management system to promote scientific management of energy saving and emission reduction.

In terms of logistics management, in addition to helping battery companies with digital warehouse management through the WMS warehouse management system, also provide smart logistics planning, combined with smart equipment and automation transformation to achieve intelligent management of lithium battery立体库 and平库.

GTRONTEC is an industrial internet enterprise strategically incubated by TCL and is also a company certified by the Ministry of Industry and Information Technology in 2022 as a national "Cross-industry跨领域 Industrial Internet Platform". TCL is the first R&D and production group in China to打通 the vertical industry chain of the semiconductor display industry. It currently has 32 manufacturing bases, covering both continuous and discrete manufacturing modes.

For the lithium battery industry, GTRONTEC can provide lithium battery enterprises with full-chain services from whole-plant consulting and planning to system software implementation, helping lithium battery enterprises build benchmark smart factories. Currently, GTRONTEC's business covers the entire new energy industry chain, including lithium battery materials, equipment, battery manufacturing, and new energy vehicles.