Changing Engines Mid-Flight: How Difficult Is It to Replace a CIM System?

If a semiconductor smart manufacturing factory is likened to a high-speed aircraft, then a CIM (Computer Integrated Manufacturing) system is the core engine that keeps it flying. For semiconductor factories that "cannot stop production day or night," replacing an entire CIM system is akin to "changing engines mid-flight"—not only must the plane keep flying, but it must do so safely.

Recently, with the support of GTRONTEC Dongzhi, Suzhou HSC Optoelectronics Technology Co., Ltd. (hereinafter referred to as Suzhou HSC) completed this "engine replacement"—switching to a new full-stack core CIM system while the factory was operating at full capacity. This made it China’s first semiconductor display smart factory with fully autonomous and controllable core CIM systems.

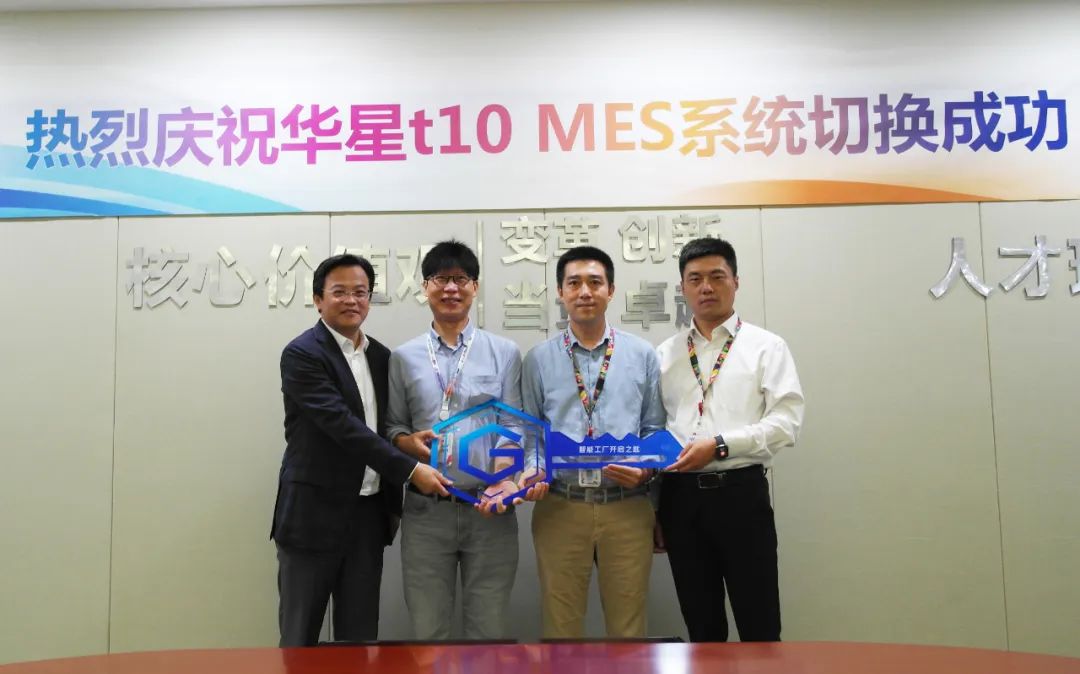

On September 23, GTRONTEC Dongzhi CEO He Jun and Suzhou HSC General Manager Ju Xia attended the "Smart Factory Key" handover ceremony.

Daring to Pioneer

Creating a Lighthouse Case for Full-Factory Semiconductor Display CIM

As a global leader in semiconductor display, Suzhou HSC urgently needed to upgrade its smart manufacturing capabilities, with the CIM system being the most critical component. However, the factory faced a major challenge: its existing CIM system, sourced from a foreign vendor, had high-level functions removed, an outdated technical framework, and could not be upgraded independently, falling far behind the company’s development and market changes.

The CIM system is known as the "lifeblood software of semiconductor factories," covering equipment management, production management, and quality management across more than 30 core systems and hundreds of subsystems. Its R&D is extremely difficult, requiring collaboration among experts and developers from multiple fields, along with validation in actual factory environments. Currently, domestic progress in this area has been slow, with core domains long constrained by foreign monopolies.

Rather than relying on others, Suzhou HSC decided to partner with GTRONTEC Dongzhi to "change engines mid-flight." Using the Dongzhi Industrial Internet Platform as a foundation and incorporating Suzhou HSC’s business characteristics, they developed a CIM system that meets world-class standards for semiconductor display factories.

In August 2020, GTRONTEC Dongzhi launched the Suzhou HSC CIM project. On September 23, 2022, with the successful switch of the most challenging MES system at the t10 factory, China’s first semiconductor display smart factory with 100% autonomous and controllable core CIM systems was born. Throughout the transition between old and new CIM systems, the factory remained at full production—an unprecedented achievement globally.

After the new CIM system went live, it not only matched the performance of the original foreign system but also exceeded it in multiple high-level functions. The factory’s automation rate reached an industry-leading 98%, enabling lean production management and optimal yield.

Tackling Challenges Head-On

Forging Core Key Capabilities

The new CIM system for Suzhou HSC, exclusively completed by GTRONTEC Dongzhi, covers planning, R&D, delivery, and后期运维, serving as a lighthouse case for full-factory semiconductor display CIM solutions. Throughout the process, GTRONTEC Dongzhi successfully overcame a series of challenges, demonstrating multiple first-class capabilities:

1. Full-Factory CIM System Upgrade Planning Capability

Since its establishment in 2018, GTRONTEC Dongzhi has focused on smart manufacturing upgrades in the semiconductor industry, accumulating extensive experience in overall digital factory solution planning.

Leveraging industrial know-how in semiconductor manufacturing and a top technical expert team, GTRONTEC Dongzhi completed the planning and R&D for Suzhou HSC’s full-factory CIM system upgrade within two years. Starting with core production software such as equipment control layer, manufacturing execution layer, and quality control layer, the upgrade covered the entire factory lifecycle, ultimately achieving self-developed core products and full autonomy over all systems.

2. Multi-Project Cluster Precision Management Capability

Suzhou HSC’s "engine replacement" involved an extensive scope, including smart factory business process architecture, technical architecture of various application systems, data architecture from底层设备 to upstream operational management, and software/hardware infrastructure—totaling over 40 projects and involving more than 500 team members. The overall implementation required a one-time successful switch of all core systems; otherwise, product data could become corrupted, equipment could fail to operate, and the entire factory could瘫痪. Even with contingency plans, full recovery would take at least 80 hours, resulting in significant losses. This relied on top-tier project management, resource allocation, and rich on-site management experience.

To tackle these challenges, GTRONTEC Dongzhi developed flexible and practical technical solutions and精细化的项目管理办法 based on a comprehensive and deep understanding of business scenarios. Collaborating with multiple business units and coordinating over a thousand people across the factory, every环节 was interlocked, leading to ultimate success.

3. Online Seamless Switching Design and Execution Capability

GTRONTEC Dongzhi innovatively proposed the strategy of building a twin CIM system, virtual reality validation, and seamless switching. First, based on existing business processes, over 30 twin CIM systems were built. Then, virtual reality validation was conducted with "zero" impact on production. Through nearly 300 iterative validation and optimization cycles, full process business scenario validation was completed, ensuring 100% matching between actual production data and virtual data, laying the foundation for a successful switch.

Finally, before the system switch, multiple rounds of switching drills were conducted with business units—from local system integration and equipment linkage to full system integration, from small batches to large batches of equipment联动, and from batch production validation to stable mass production. Each layer of testing ensured that the twin CIM system could seamlessly replace the original system.

Innovation and Breakthrough

Continuous Investment in Semiconductor CIM Product R&D, Achieving IT and OT Integration

Beyond Suzhou HSC, GTRONTEC Dongzhi’s smart CIM solutions for semiconductor factories have been implemented in multiple facilities, enabling production management, quality traceability, and process optimization from wafers and晶圆制造 to packaging testing and finished product assembly, across multiple factories and workshops.

GTRONTEC Dongzhi’s core semiconductor CIM products are categorized by service object into production control, equipment management, and quality optimization: including MES (Manufacturing Execution System), EAP (Equipment Automation Program), APS (Advanced Planning and Scheduling); RMS (Recipe Management System), FDC (Fault Detection and Classification), APC (Advanced Process Control), RCM (Remote Control Management); YMS (Yield Management System), SPC (Statistical Process Control), and QMS (Quality Management System), among others.

Additionally, GTRONTEC Dongzhi believes that the smart manufacturing transformation of semiconductor factories has entered a deep phase, requiring not only CIM systems from an IT perspective but also fully leveraging data value. Using innovative technologies like IoT, AI, and big data, they empower OT-side底层设备, driving intelligent upgrades in equipment and edge control hardware through software and algorithms. Currently, GTRONTEC Dongzhi has developed multiple data intelligence products in the semiconductor field, such as "cloud-edge-device integrated intelligent monitoring" for semiconductor equipment and virtual metrology for specific processes (e.g., CMP, CVD).

At present, domestic semiconductor smart manufacturing is booming, but the localization journey remains long and challenging. As a "core force" in the semiconductor field committed to promoting industry development through autonomous and controllable means, GTRONTEC Dongzhi will continue to innovate and break through in core technologies, empowering the advancement of the domestic semiconductor industry.