GTRONTEC MFA: Breaking Through Yield Management Bottlenecks in Wafer Fabs -- Replication

With the continuous advancement of semiconductor technology and equipment evolution, wafer manufacturing processes are rapidly progressing, transistor density is multiplying, and the difficulty of chip manufacturing yield management is increasing exponentially.

Especially in wafer fabs pursuing advanced processes, while striving to balance mass production pressure and yield metrics, the complexity of yield management continues to rise, urgently requiring more advanced solutions like MFA Multi-Factor Analysis to break through yield management bottlenecks.

Currently, wafer fabs face increasingly severe quality management challenges:

On one hand, production continuously generates vast amounts of structured and unstructured data, with numerous factors affecting yield and complex logic. Process engineers spend hours pulling production line machine data to view single-factor distribution trends and locate abnormal factors, unable to promptly and accurately identify influencing factors and resolve issues.

On the other hand, many business data require additional development and presentation, leading to information lag and difficulty in data linkage. Frontline operational staff urgently need convenient, visually supported data analysis tools.

"We believe the key to breaking through chip manufacturing yield management in the future lies in big data analysis and intelligent prediction—by fully mining and unleashing the value of massive data, timely analyzing influencing factors, and predicting and alerting quality anomalies.

Currently, GTRONTEC's Multi-Factor Analysis system MFA, through monitoring, statistical analysis, modeling, and analysis of process data, combined with visual inspection methods, can efficiently and effectively solve quality improvement challenges in wafer fabs."

said Xiao Changbao, Vice President of R&D at GTRONTEC's Semiconductor Business Unit.

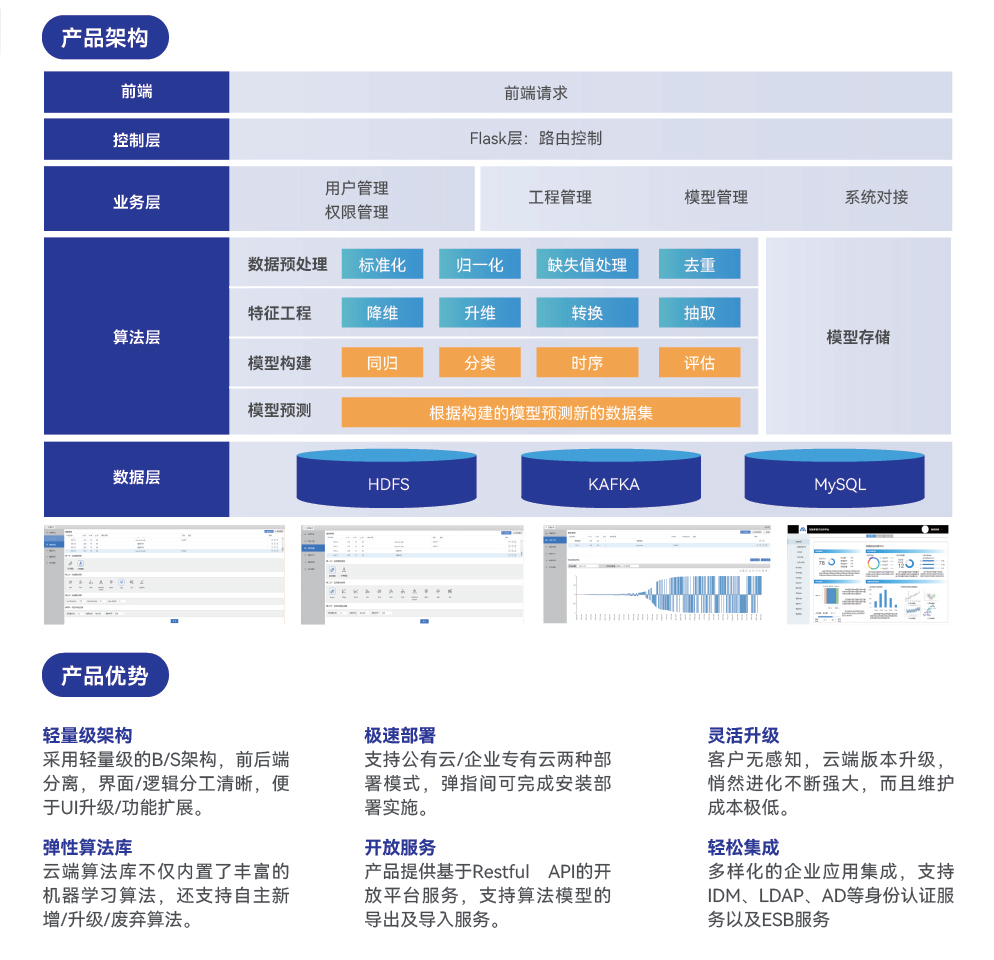

Addressing the common yield management challenges faced by wafer fabs, GTRONTEC's MFA product offers significant technical and application advantages in deep analysis for quality improvement scenarios. It enables intelligent, rapid, and precise analysis of factory data, and through quality control, yield prediction, abnormal factor mining, and other industrial applications—coupled with real-time model prediction, monitoring alerts, and production system integration—helps companies automatically complete anomaly monitoring and real-time processing, making quality management smarter and more efficient.

At the same time, GTRONTEC MFA balances technological leadership with user experience.

Especially for frontline engineers, GTRONTEC MFA is easy to use, flexible, and rich in algorithmic models. As a zero-code, visual, interactive multi-factor analysis tool, it helps users independently perform root cause analysis, quality prediction, process parameter adjustment, and other multi-scenario analyses. Applications in the same scenario can be quickly replicated—even engineers without specialized data backgrounds can easily create big data analysis models and perform multi-dimensional data analysis through drag-and-drop, even customizing data analysis, deploying it promptly, and applying it to production to solve business problems.

Leveraging these unique advantages, GTRONTEC MFA is delivering tangible benefits to semiconductor industry customers:

Take, for example, a semiconductor company served earlier. Its process inspection was complex with long sampling cycles, prone to causing batch losses of raw materials and products. When inspection data was insufficient, issues like abnormal product flow occurred.

By using GTRONTEC MFA's virtual measurement tool, cleaning thousands of factors, repeatedly fitting and correcting, and generating a real-time full-inspection 'characteristic value' model, the company could predict product characteristic values in real time, achieving comprehensive quality control. This reduced abnormal product quantity by 90%, increased comprehensive product line yield by 1.5%, reduced sampling frequency by 60%, and improved output capacity by approximately 2,200 wafers per month.

As one of the few domestic manufacturers with self-developed products deployed across the upstream, midstream, and downstream of the industry chain, GTRONTEC currently serves semiconductor customers covering semiconductor materials, wafer manufacturing, packaging and testing, and semiconductor equipment. It offers a complete product and service matrix for quality management, including SPC for intelligent issue identification and monitoring, YMS for intelligent analysis, ADC for visual inspection solutions, and more. Through integrated one-stop solutions, it helps wafer fabs effectively enhance quality management and overcome yield management challenges.

To learn more about product/solution details, please contact tel/WeChat: 400-600-2869.