Intelligent Operation and Maintenance of Lithium Battery Equipment: Starting with Ensuring Stable Operation of Slurry Mixers

"The lithium battery industry is in a phase of capacity expansion. How to shorten the production ramp-up period through digital means while ensuring product quality and reducing the manufacturing cost per watt-hour is the core challenge for the industry's digital transformation," said Dr. Li Nan, General Manager of Gechuangdongzhi's New Energy Division.

In lithium battery manufacturing, slurry mixing is one of the core processes in the preliminary electrode manufacturing stage. The quality of the slurry directly affects subsequent processes and is a critical factor in determining electrode consistency. Besides slurry mixing technology, the mixing equipment itself is also crucial.

A stably operating slurry mixer can ensure consistency in the slurry, electrodes, and ultimately the lithium batteries from the initial processes.

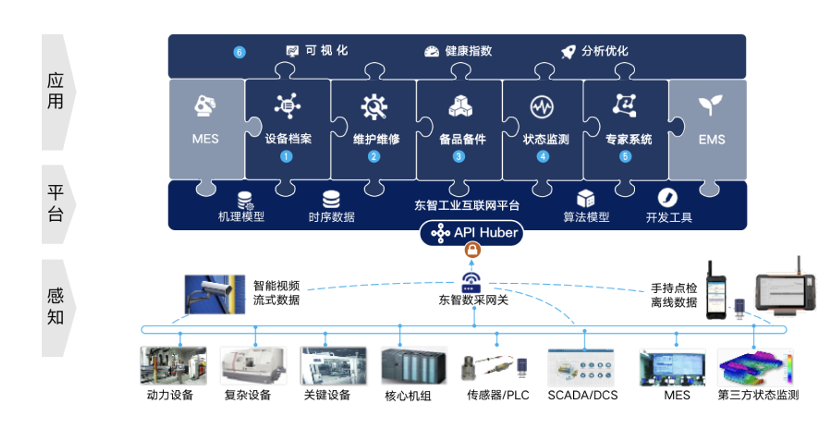

Addressing the core pain points of the lithium battery industry, Gechuangdongzhi has launched a device health management solution tailored for the industry. Through integrated hardware and software, it enables real-time monitoring, dynamic sensing, early warning, coordinated handling, intelligent maintenance, and diagnostics for core equipment such as mixers and coating machines, providing comprehensive intelligent health management.

Additionally, it builds a multi-source data fusion model for equipment fault diagnosis and prediction, enabling predictive maintenance, reducing maintenance risks, avoiding losses from sudden equipment downtime, ensuring operational stability, and maximizing lithium battery consistency at the equipment level to effectively activate production capacity.

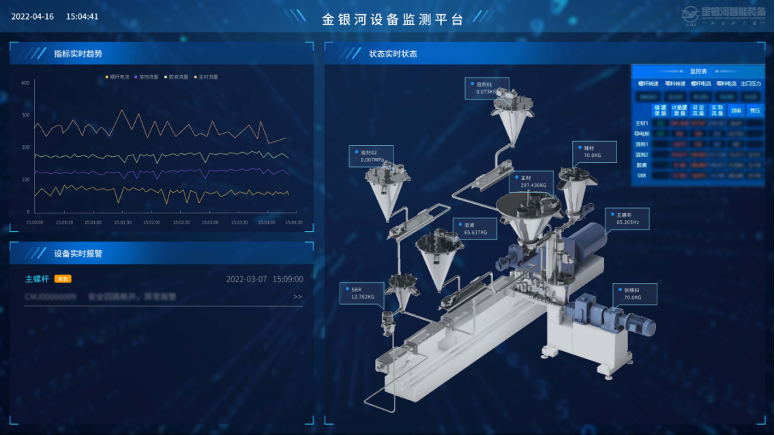

Taking Foshan Jinyuanhua Intelligent Equipment Co., Ltd. (hereinafter referred to as "Jinyuanhua") as an example, Gechuangdongzhi implemented its equipment health management solution in Jinyuanhua's lithium battery slurry production line. By integrating and analyzing multi-source data from the production line and combining it with Jinyuanhua's equipment experts' process knowledge, the solution enables effective monitoring of mechanical and electrical faults, promotes structured accumulation of maintenance knowledge, and provides efficient remote equipment maintenance and other value-added services for customers, ensuring on-site equipment stability.

For core equipment commonly used in lithium battery material production, such as industrial pumps, compressors, pre-mixing machines for cells, and coating machines, the solution deeply integrates artificial intelligence with industrial mechanisms, using self-developed high-frequency data acquisition to achieve comprehensive equipment health sensing and predictive maintenance. For various manufacturing equipment in lithium battery production, especially non-standard equipment in mid-line and module Pack lines, it provides a closed-loop intelligent maintenance management service covering daily maintenance, fault handling, spare parts, personnel performance, and knowledge base.

To learn more about our products/solutions, please contact us at phone/WeChat: 400-600-2869.