How to enhance overall equipment efficiency? Adopting the new generation FDC is imperative

FDCSystem serves as key support for high-frequency process parameter warnings,in8-inch,12-inch wafer fabs and advanced packaging/testing plants in semiconductor manufacturing, it is almost a rigid demand for every factory. It helps equipment engineers and related departments by real-time detection and calculation of machine data and process parameters, achieving2major effects: first, timely detection of product defects caused by process parameter issues, improving yield; second, intelligent equipment maintenance, accurately judgingPM(preventive maintenance) timing, and verifyingPMresults, ensuring production efficiency.

However, as transistor counts on chips double, semiconductor manufacturing equipment and quality control difficulties grow exponentially. Meanwhile, processes and equipment iterate, traditionalFDCsystems or methods can no longer meet the needs for overall equipment efficiency control and improvement.

The solution is based on advanced technology architecture ofnew generationFDC, compared to previous generation, it uses latest big data tech, supports high-throughput, low-latency real-time computing, excels in real-time anomaly detection and root cause analysis, better suited for real-time monitoring.

Users of traditionalFDCoften face high barriers, need extensive tech support, maintain many models,无效alarms unmanageable,BIfunction缺失. Key is, as semiconductor factories demand near-zero tolerance for faults, unplanned downtime, and strict yield control, need for real-time fault detection, data processing, and timely warnings surges.

TraditionalFDCis feature-rich, long-serving, but expensive, no customization, slow iteration. Due to old architecture, complex deployment, noHA,实现Failover via application layer; monolithic, no microservices; no real-time big data or time-series DB, uses relational DB sharding for performance. Thus closed system, cannot meet diverse data analysis and real-time warning needs quickly.

Using new generationFDC, through closed-loop control reduces anomaly impact,全面提升equipment efficiency, supporting semiconductor factories in improving quality control and management efficiency, reducing scrap and rework rates due to equipment issues.

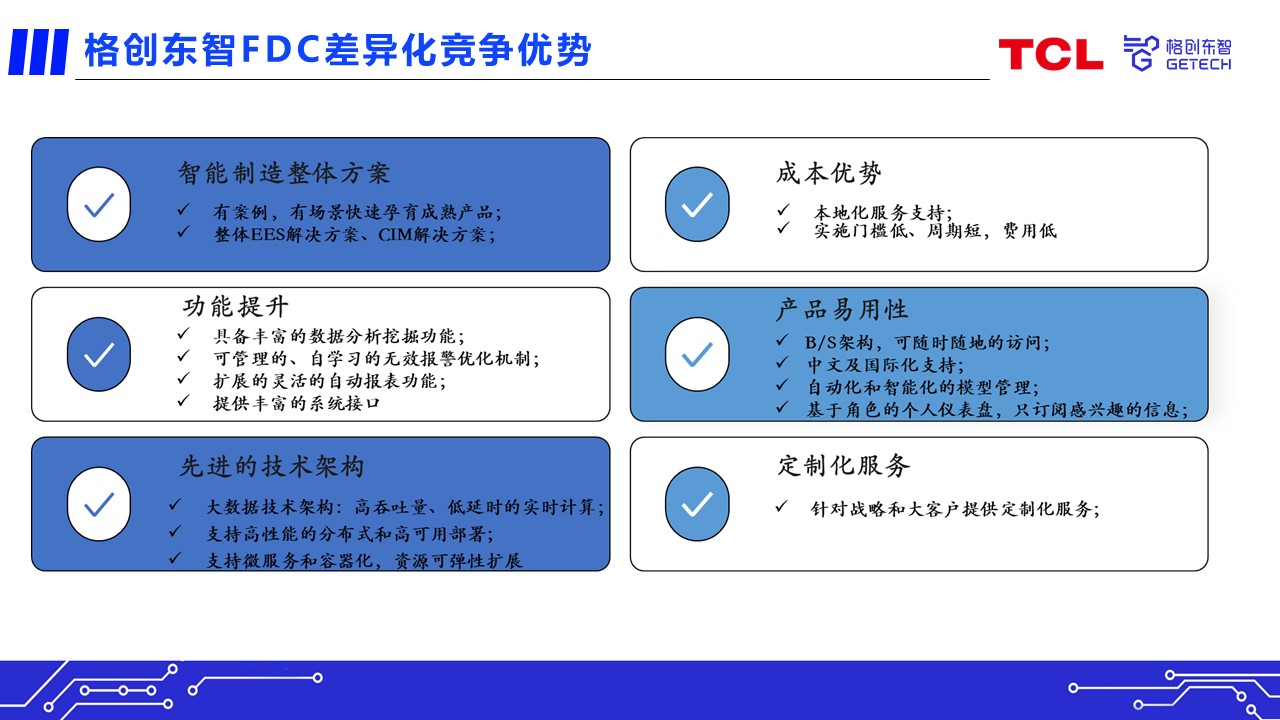

At product tech level, new generation FDCuses advanced architecture, supports high-throughput, low-latency real-time computing; allows high-performance distributed and high-availability deployment; supports microservices and containerization, elastic resource scaling; usability greatly improved over traditionalFDC, GTRONTECFDCoffers extensive configuration and customization, freeing定制development, enabling flexible, quick new functions without coding, and supports role-based personal dashboard订阅.

As a key domestic vendor of semiconductor smart manufacturing softwareCIM, GTRONTEC developed upgradedFDC, with three core advantages:

First,performance boost from new architecture, usingFlinkreal-time computing framework and relational DB sharding for high performance;

Second,upgraded real-time detection analysis: comprehensive data detection algorithms, automated and intelligent model management, flexible parameter analysis and detection simulation;

Third,optimized alarm mechanism, closed-loop feedback effectively reduces无效alarms.

| Learn more about product/solution details, welcome to consult phone/WeChat: 400-600-2869. |