Breaking the Ice from Implementation Scenarios, Deeply Mining Industrial Field Data Value

The application of industrial data must be scenario-driven. Only data intelligence analysis applications based on a deep understanding of the industrial site can truly bring data monetization to enterprises.

In the digital era, data is regarded as 'new era oil'. In 2020, the central government首次将数据作为新型生产要素,纳入市场化配置的生产要素,成为最具战略意义的资产之一。

Currently, digital transformation has become a necessity for enterprise survival. However, for enterprises in the transformation stage, the inability to effectively mine the value of data 'frozen' in storage devices and data growing exponentially daily becomes a key constraint on business development, given the diverse characteristics of data from various enterprise information systems and data platforms.

Facing the increasingly massive data volume, how to extract valuable data has become a major challenge for enterprises. 'Finding the right implementation scenario is key to industrial data intelligent applications,' said GTRONTEC, the only 'dual-cross' platform originating from the semiconductor industry, in a recent interview with Industrial Internet World. GTRONTEC stated that industrial data applications must be scenario-driven. For industrial site data applications, simple data mid-platforms (data infra) cannot fully unlock data value; only data intelligence analysis applications based on a deep understanding of the industrial site can truly bring data monetization to enterprises.

01

What are the challenges of industrial data intelligent applications?

In the wave of digital transformation in manufacturing, maximizing data value has immeasurable benefits for the entire industry. However, GTRONTEC noted that industrial intelligent data is still in the early exploration stage, facing many challenges in data application.

First, data foundation capabilities remain weak. Issues like data silos, missing data collection, and weak data connectivity and governance lead to low data integration, making analysis difficult. Especially on the production site, challenges include data chimneys between different production steps and equipment, and redundant data collection.

Second, data across the industry chain is not connected. Due to the inherent characteristics of enterprise data infrastructure (e.g., private deployment) and data security concerns, many enterprises are hesitant to connect industry chain data. Industrial site data has diverse types, large volume, and uneven distribution. How to collect and manage data, particularly in data-intensive fields like semiconductors, and whether it is necessary to collect all data, are questions enterprises must ponder. Achieving a leap from local optimization within a single enterprise to global optimization across the entire industry chain requires data flow between upstream and downstream enterprises, facing challenges in security compliance, business models, and technical standards.

Third, data application scenarios are difficult to implement. Even if data silos and processing issues are resolved, how to apply data and which scenarios are most valuable are critical. Currently, cases of cost reduction and efficiency improvement through data are still accumulating. Meanwhile, on the factory frontline, engineers often lack professional data analysis training and need lightweight, low-code, easy-to-use tools to match their data analysis needs, which is another reason data applications fail to land.

02

Breaking the ice from implementation scenarios to mine data value

'Currently, data intelligent applications are hotly discussed, but implementation is still at a relatively early stage,' GTRONTEC believes. Finding the right scenarios, tools, and 'combinations' can release the greatest value for enterprises. We need to focus on scenarios with sufficient data volume, rich features, and high economic return, such as equipment management and quality analysis in high-end manufacturing. High-end manufacturing, like semiconductors and new energy, has high automation, good data foundation, and high equipment and quality maintenance costs, making them fertile ground for data mining. After identifying scenarios, user-friendly tools are crucial.

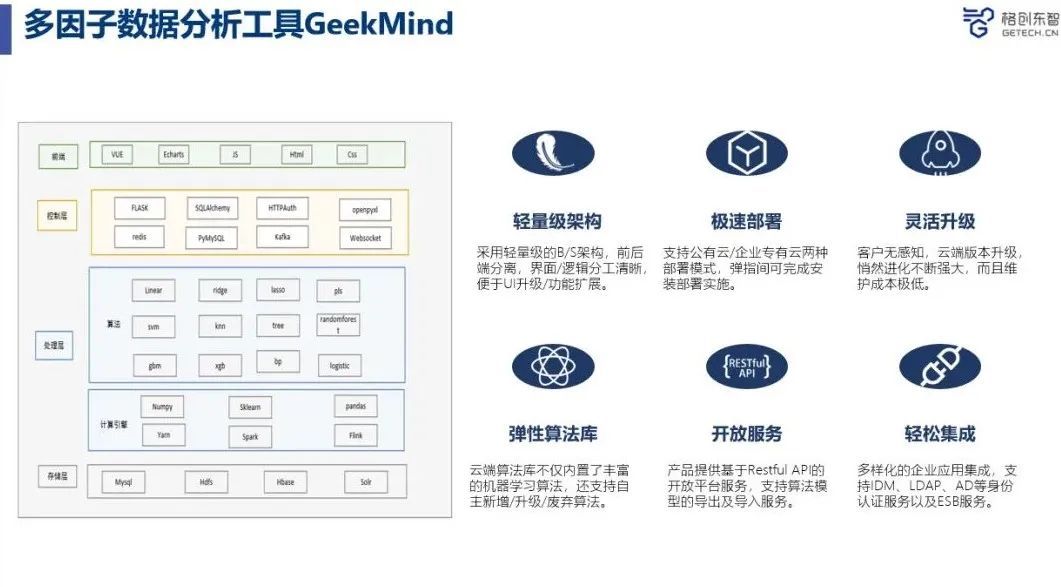

Due to technical and background limitations, many factory personnel do not know how to transform production pain points into data-driven solutions. Meanwhile, professional models and data analysis tools are difficult for them to operate. Their core need is problem-solving, so they prefer convenient, easy-to-use tools. GTRONTEC stated that tools like GeekMind, with lightweight, easy-to-understand, low-code, modular features, are not only easy to operate but also simple to learn and deploy, including many machine learning models practiced in industrial sites. Factory frontline engineers, even without specialized data background, can easily create big data analysis models via drag-and-drop, perform multi-dimensional data analysis, and even customize analysis to solve frontline problems.

GTRONTEC told reporters that it leads the industry in implementation scenarios. In quality analysis, GeekMind has been used multiple times to improve quality by analyzing multiple links and factors affecting product quality, predicting the impact of previous processes, enabling real-time automatic prediction of product characteristics, comprehensive quality monitoring, and timely discovery and prevention of quality issues, aiming to increase factory yield and shorten production cycles. In leading customers' production sites, it has brought tens of millions in cost reduction. Additionally, in quality analysis, GTRONTEC leverages its product portfolio and platform advantages, using a 'combination punch' approach. Besides big data analysis, it integrates other products (e.g., yield management system YMS, single-factor quality analysis SPC, quality system management QMS) into quality analysis solutions to solve complex problems.

03

Focusing on core advantages, building product barriers

Since its establishment in 2018, based on TCL's over 40 years of manufacturing experience, GTRONTEC has 'rooted' in every aspect of production, focusing on advanced manufacturing and production sites. In four years, it has not only built the only national 'dual-cross' platform originating from semiconductor manufacturing—Dongzhi Industrial Application Intelligent Platform, providing one-stop solutions from edge data collection to top-level application development, but also refined dozens of killer apps in production control, equipment management, quality optimization, and supply chain services.

It has created hundreds of benchmark digital transformation cases for leading manufacturing enterprises in over 20 industries including泛半导体, 3C electronics, new energy, petrochemicals, auto parts, steel, and pharmaceuticals, gaining recognition from the market and government departments.

Regarding future plans for data intelligent products, GTRONTEC stated: first, it will continue to address 'bottleneck' issues in the domestic semiconductor industry, focusing on key industries like泛半导体 and new energy for strategic empowerment under the trend of strong localization innovation demand; second, it will strengthen its advantages, form product strengths and barriers, focus on production sites, empower industrial data value monetization, and firmly integrate data intelligence into products; third, under the dual-carbon goals, Gechuang is exploring the valorization of dual-carbon data to promote digital and green processes in manufacturing.

Although the industrial data intelligence track is crowded with 'seed players', GTRONTEC, with its own advantages and characteristics, has significant strengths in data mining and intelligent analysis, contributing importantly to deepening data value mining and promoting high-quality development of industrial internet.