Retained! MIIT Announces 2022 List of Excellent Industrial Internet APP Solutions

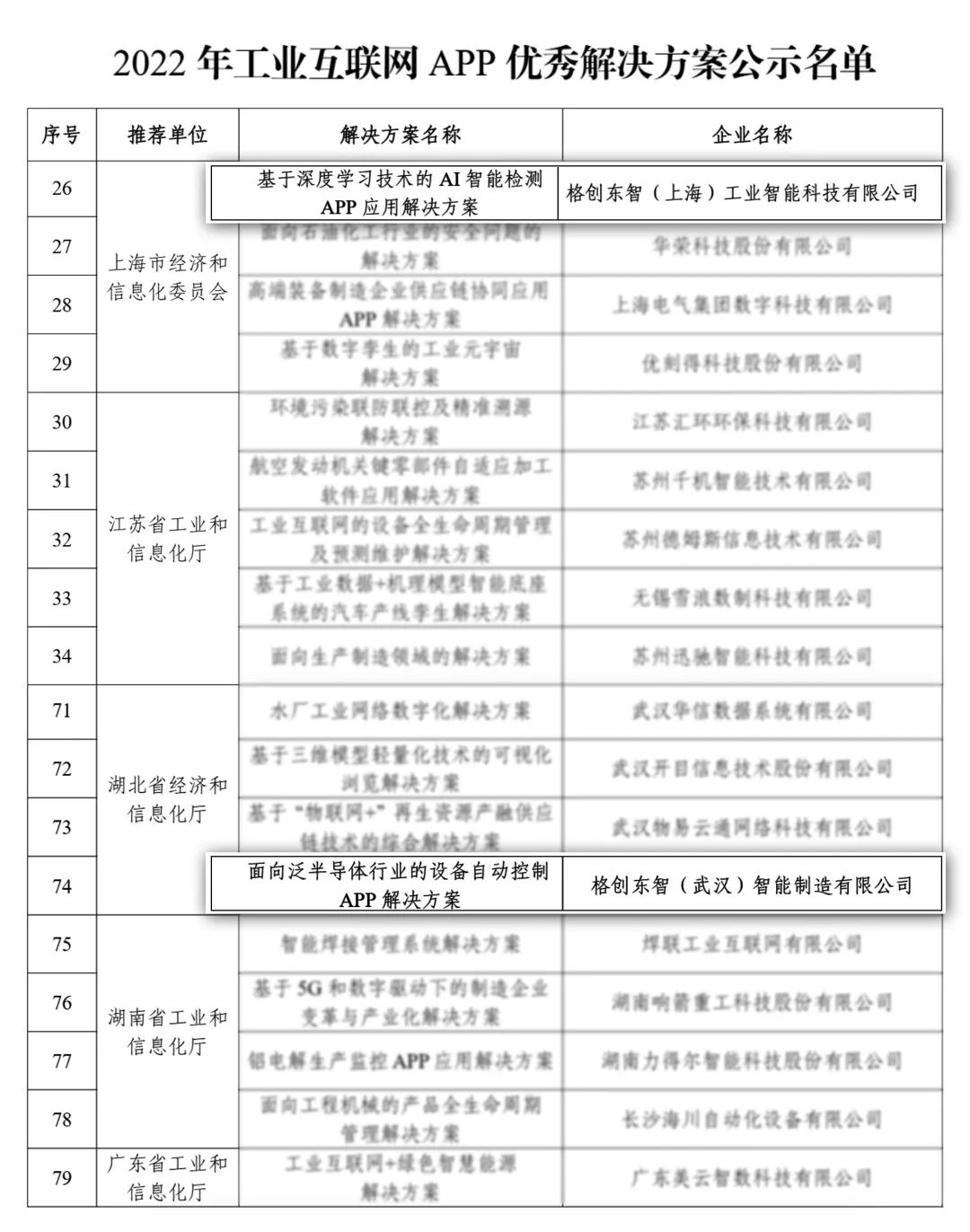

On January 13, MIIT released the '2022 List of Excellent Industrial Internet APP Solutions', and GTRONTEC Dongzhi's 'AI Intelligent Detection (Tianshu AI) APP Solution Based on Deep Learning Technology' and 'Equipment Automation (EAP) APP Solution for the Pan-Semiconductor Industry' were selected.

This is after 'MFA Multi-Factor Analysis APP Solution' and 'Equipment Health Management (EHM) APP Solution Based on Industrial Internet', GTRONTEC Dongzhi's self-developed products have been selected again in the most authoritative certification list in the industrial internet field.

In November 2022, MIIT organized the collection and selection of 2022 Excellent Industrial Internet APP Solutions, mainly including four types: key support industrial APP, basic common industrial APP, industry general industrial APP, and enterprise specific industrial APP. MIIT systematically evaluated from dimensions such as project comprehensive strength, key technological innovation, economic and social benefits, and industrialization promotion value.

According to MIIT requirements, excellent solutions should solve actual industrial needs, play a significant supporting and leading role in improving quality and efficiency, and transformation and upgrading of enterprises. At the same time, they need to have independent intellectual property rights, advanced technology, and be industrialized or deployed.

#01

AI Intelligent Detection (Tianshu AI) APP Solution Based on Deep Learning Technology

Quality inspection has always been a critical link in the manufacturing process. With the advent of the digital era, technologies such as AI and IoT are gradually applied to traditional quality inspection, helping to upgrade inspection, achieve cost reduction and efficiency improvement. GTRONTEC Dongzhi's 'AI Intelligent Detection (Tianshu AI) APP Solution Based on Deep Learning Technology' focuses on AI detection in advanced manufacturing, with an industrial visual deep learning engine integrating 'sensing, storage, computing, and knowledge', creating an integrated data collection scheme of 'image + video + optics', establishing a 360-degree data information database; contains a tens of millions-level industry feature database, improving inspection accuracy; has multi-task, composite toolkits, covering various application scenarios in industrial inspection.

Currently, Tianshu AI has been applied in multiple industrial scenarios. Based on this, the ADC (Artificial Intelligence Automatic Defect Classification) system implemented in TCL CSOT production line is the first truly deployed AI application in China's semiconductor display industry. Compared to traditional manual inspection, the ADC system significantly improves inspection efficiency, replacing over 50% of manpower; AI recognition speed increases by 5-10 times, accuracy improves from human eye's 85% to over 90%.

#02

Equipment Automatic Control (EAP) APP Solution for the Pan-Semiconductor Industry

With the development and upgrade of semiconductor processes, wafer fabs continuously pursue higher production efficiency and lower costs. In this process, the Equipment Automation (EAP) system, as a bridge between MES and semiconductor equipment, is increasingly important.

As an important part of GTRONTEC Dongzhi's semiconductor CIM overall solution, the semiconductor EAP system is compatible with multiple protocols, achieving real-time data collection, dynamic equipment monitoring, and reverse instruction control functions, with advantages in improving product yield and intelligent management, providing strong support for production efficiency improvement and cost reduction.

Taking a chip factory served by GTRONTEC Dongzhi as an example, to meet the needs of systematic management and production automation in a new production line, the factory wanted real-time monitoring of the status of people, machines, and materials in the process, achieving pre-warning and post-traceability, improving error prevention, and enhancing big data analysis capabilities.

To address this need, GTRONTEC Dongzhi built an EAP system for the customer, and through good coordination with other key systems, achieved data conversion and integration for the entire line, real-time insight into upstream and downstream status, thus improving production efficiency by over 20%; by collecting WIP process data and equipment utility data on time, managing equipment sampling rules, product yield increased by 3%; finally, by打通 controlling the input-output of all products in the equipment line, saving inter-equipment搬运 transfer costs, and real-time掌握 equipment status, quickly排除异常原因, reducing factory costs by 10%.

Industrial APP is an important outcome of industrial technology softwareization and a key factor in forming the core competitiveness of industrial internet platforms. GTRONTEC Dongzhi has always been committed to technological innovation and practical application in the industrial software field, promoting the acceleration of localization of industrial software.

Under industry consensus and policy guidance, GTRONTEC Dongzhi first focuses on modeling industrial data and continuously optimizing models, and second on refining and abstracting existing industrial technical knowledge. As of now, the Dongzhi platform has沉淀 nearly 30,000 industrial models and accumulated over 10,000 industrial APPs.

To learn more about product/solution details, welcome to consult phone/WeChat: 400-600-2869.