How do semiconductor factories conduct quality management? Insights from an expert with over a hundred QMS projects

The global semiconductor market is experiencing severe cyclical fluctuations; on one hand, the market demand for smartphone chips and memory chips remains weak, on the other hand, the rapid growth of smart cars has ignited strong demand for SiC.

Regardless of the challenge, for semiconductor factories, strengthening quality management is key to breaking through cycles. The importance of semiconductor chip quality management is increasingly prominent, and QMS will become as essential as CIM systems.

How does QMS conduct quality management?

Listen to what an expert with over a hundred QMS projects has to say

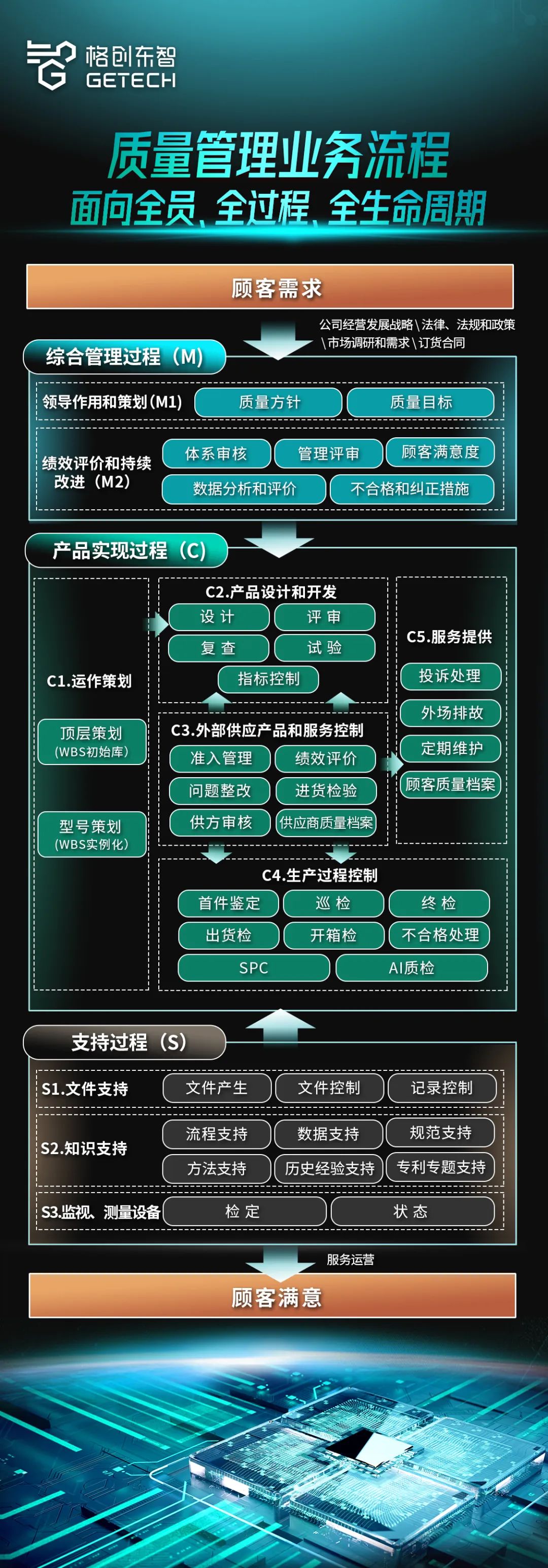

Semiconductor quality management business processes span design, procurement, incoming materials, production, testing, after-sales, and other product realization processes, while also covering comprehensive management and support processes.

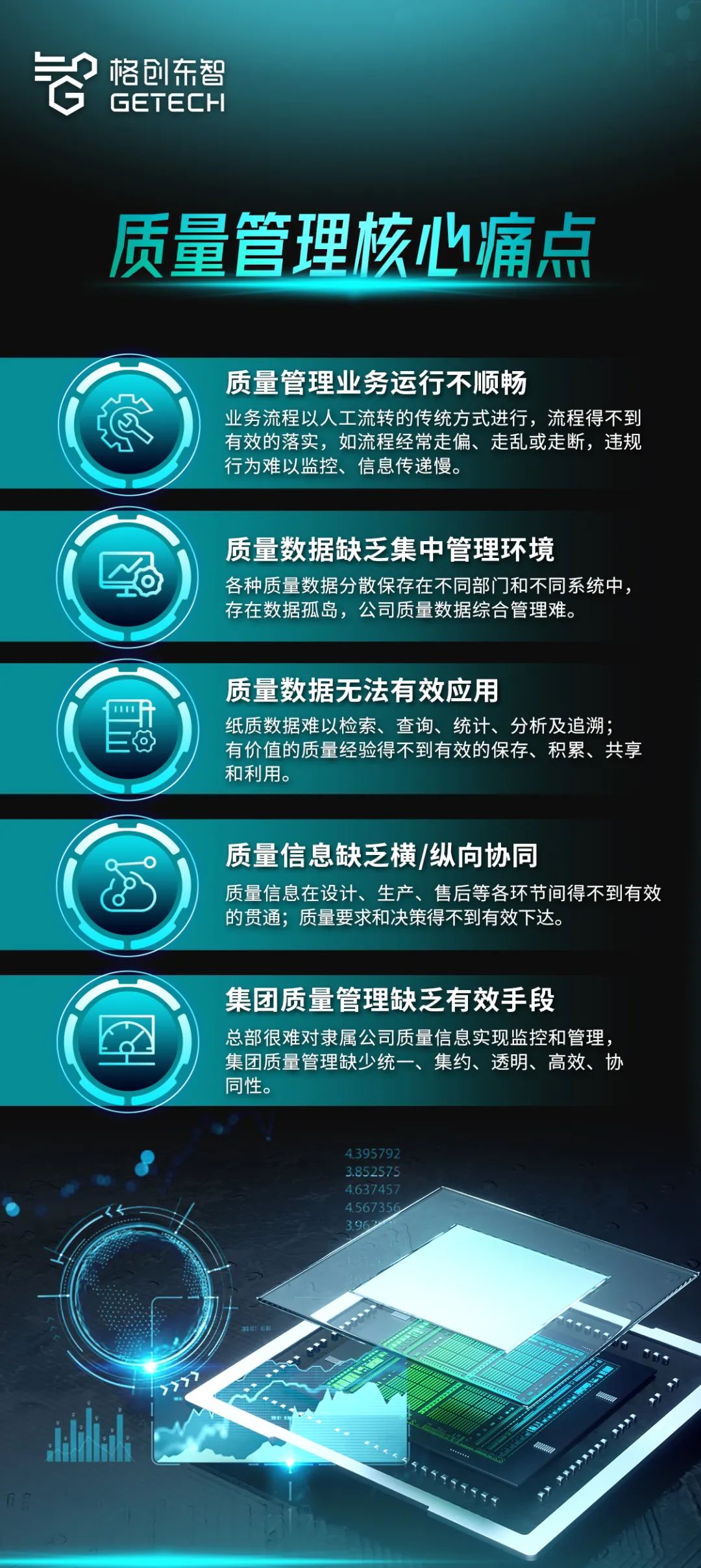

The complexity of quality management and lack of management methods bring many difficulties to quality management.

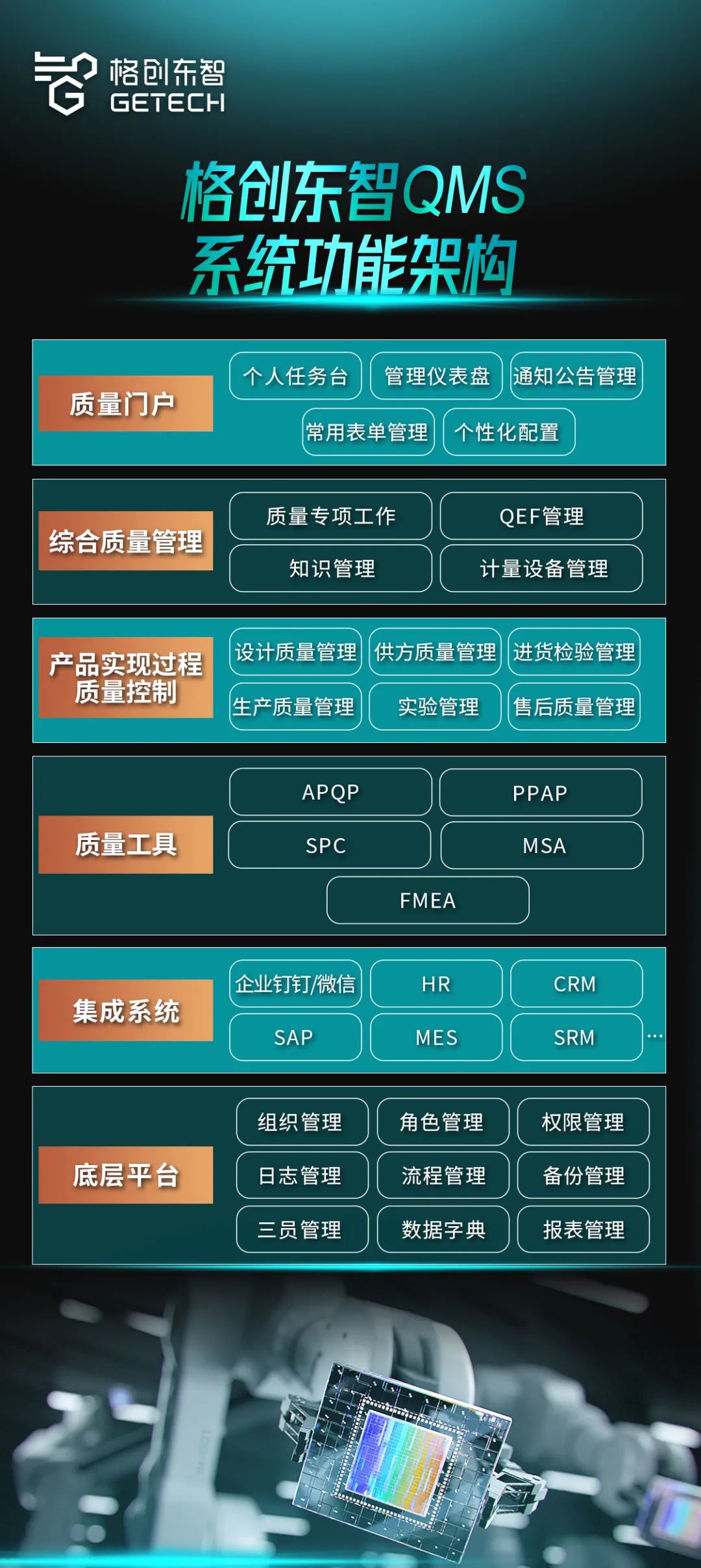

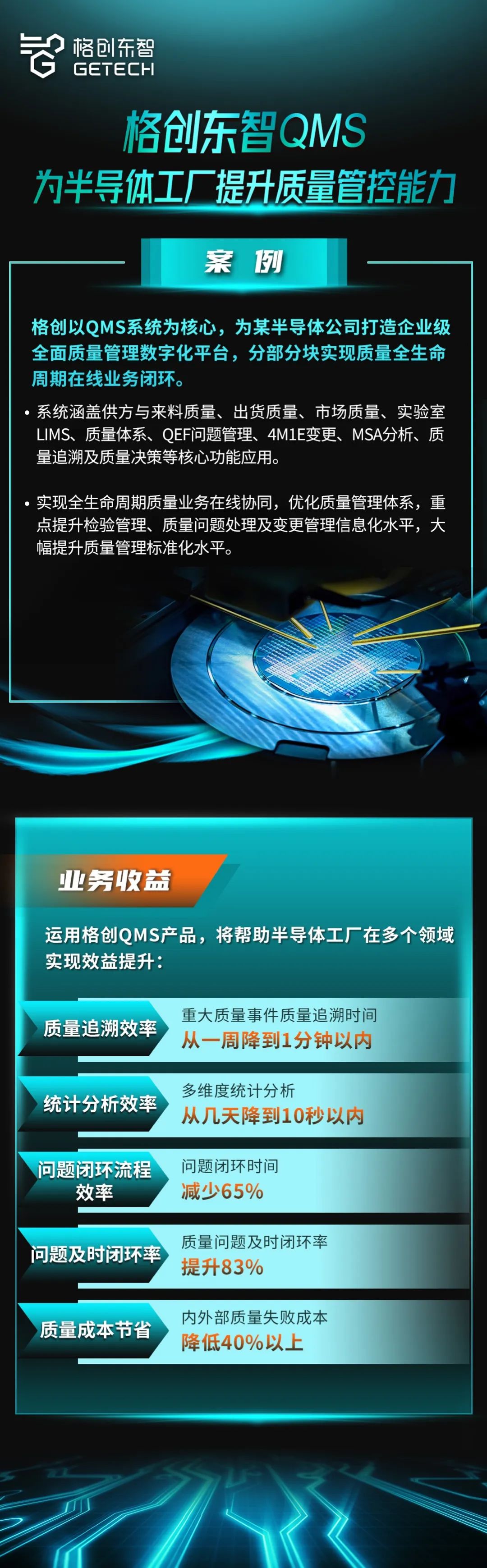

What improvements will GTRONTEC Dongzhi QMS product bring to semiconductor factories?

GTRONTEC Dongzhi builds a QMS full value chain information flow for semiconductor factories, eliminating quality information 'islands', achieving centralized, standardized, and efficient management of quality data, and reducing quality costs.

GTRONTEC Dongzhi QMS system has been implemented in multiple semiconductor factories in China, significantly reducing costs and improving efficiency.

| To learn more about product/solution details, welcome to consult via phone/WeChat: 400-600-2869. |