These pain points faced by semiconductor manufacturing plants can actually be solved by the RCM system—Copy

As a representative of high-end manufacturing, semiconductor manufacturing plants have evolved from semi-automated operations to fully automated operations, moving toward the ultimate goal of unmanned factories (lights-out factories). However, during the process of smart upgrades, semiconductor manufacturing plants also face many problems and challenges.

l Preparation work before entering the clean room is cumbersome, and frequent personnel movement negatively impacts the clean environment.

l Factory areas are often very large, with various equipment scattered throughout, making maintenance and operations time-consuming and labor-intensive.

l Third-party software installation on equipment computers is not allowed, posing risks of information security leaks or virus infections.

l During equipment maintenance, personnel often perform repetitive, simple, and low-level operations, resulting in high labor intensity and significant manpower loss.

l When integrating with systems like SECS, CCTV, and MES, there is a lack of unified integration of API interface resources.

Is there a solution that can reduce personnel entry, allow remote control of equipment without personnel entering, or replace manual operations with automated programs?

Yes!

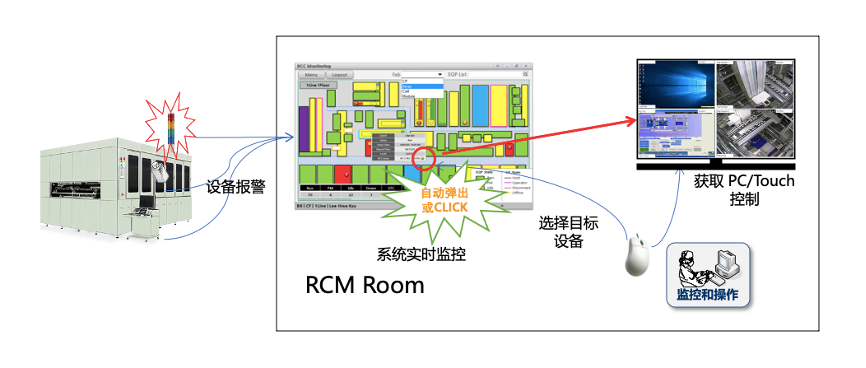

To address the above problems and challenges, GTRONTEC East Wisdom's RCM (Remote Control Management) Equipment Remote Control Management System (hereinafter referred to as the RCM system) provides a KVM-over-IP monitoring and management solution for semiconductor clean rooms. By connecting the computer's keyboard, screen, and mouse signals to RCM hardware and processing them with specialized technology, the three signals are remotely transmitted via network cables, allowing users to control computers and manage equipment in real-time from a distance, reducing pollution caused by frequent personnel movement in the clean environment.

Additionally, by incorporating OCR screen image recognition technology, RPA robotic process automation technology (using scripts for automated operations), and positioning technology, the system shortens the time required for abnormal handling and restarting, greatly improving production efficiency and overall equipment effectiveness while reducing product defect rates.

Specifically, the RCM system has the following 8 application modules in the semiconductor industry:

l Remote Monitoring: Centralized control room for unified equipment control, displaying the human-machine interface of production equipment in real-time.

l Automatic Operation: Automatically performs operations based on script inputs by judging the current equipment interface.

l System Integration: Real-time linkage with MES, integrating production data.

l Autonomous Analysis: Connects defect detection results with the YMS analysis module.

l Precise Dispatching: Dispatches the nearest engineer to resolve on-site equipment issues based on personnel availability and equipment location.

l Dashboard Display: Unified equipment management with customizable multi-grid dashboard displays.

l Real-Time Recording: Real-time observation and recording of equipment operation screens.

l Video Playback: Allows playback of production site videos; matches production monitoring system videos in case of alerts.

Through these 8 applications, the RCM system will help semiconductor manufacturing plants improve work efficiency, increase the human-machine ratio, effectively enhance equipment capacity, reduce equipment procurement costs, and achieve an upgrade to smart manufacturing.

To learn more about GTRONTEC East Wisdom's RCM Equipment Remote Control System product/solution details, please call 400-600-2869 (same number for WeChat). GTRONTEC East Wisdom's professional team will tailor a customized solution for you.