Dongzhi FDC: Speed is Key, Essential QC Tool for Semiconductor Engineers

For semiconductor factories that regard product yield as a lifeline,

in the production manufacturing process,

equipment stability and process consistency,

are important factors to ensure or even improve yield.

Facing thousands of process equipment in the factory,

engineers must have the ability to monitor and control process changes in real-time,

comprehensively and meticulously manage equipment,

reduce damage to production quality from equipment abnormalities.

With FDC (Equipment Fault Detection and Classification System), engineers can monitor production equipment 24/7 uninterrupted, quickly discover issues and intervene promptly, therefore, we define FDC as the 'timely help' for quality control.

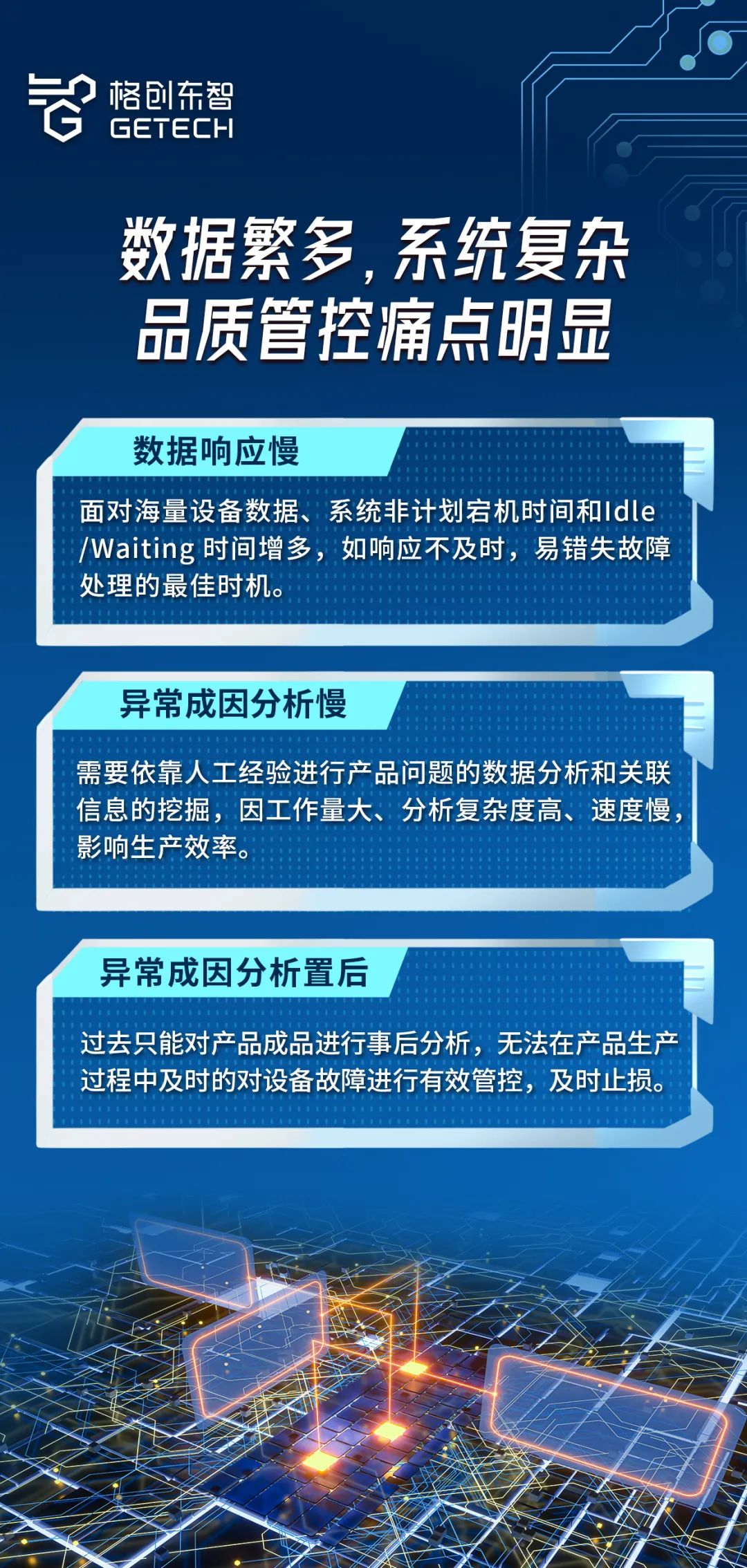

In traditional semiconductor factories, facing massive equipment data and complex operating systems, engineers often find quality control challenging, and they usually face the following difficulties:

Dongzhi FDC adopts a newly upgraded big data technology architecture, supports high-throughput, low-latency real-time computing, through rapid response, analysis, and application, performs real-time production anomaly detection, and quickly identifies and analyzes root causes.

If you are interested in our product solutions, please contact us: 400-600-2869 (same for phone/WeChat). We will help you understand how the latest generation FDC and other systems can assist you on the path to smart manufacturing.