Why is the RCM Semiconductor Equipment Remote Control Management System needed? What is the principle of the RCM system?

Under the wave of global smart manufacturing, China's manufacturing industry is actively upgrading and transforming, with greatly improved automation, digitalization, and networking levels. Production equipment is increasingly integrated and intelligent, with enhanced data visualization and simpler operation. However, this comes with increased difficulty in equipment maintenance and repair, higher maintenance costs, and the growing importance of equipment upkeep. Especially in the semiconductor industry, known as the pearl of manufacturing.

Why is the RCM Semiconductor Equipment Remote Control Management System needed

As a typical heavy-asset industry, semiconductor factory equipment investment can account for 60%-70% of capital expenditure, with many types and large quantities of equipment, mostly imported and expensive, leading to significant losses from unexpected downtime. Additionally, factories must balance preventive maintenance needs for multiple production lines and equipment with the risk of preventing unexpected停机.

Moreover, in industries such as semiconductor design and manufacturing, packaging and testing, and display panel production, due to the use of many high-precision instruments, production must occur in clean or even dust-free environments to avoid contamination from airborne particles like metal ions and organic matter, which can reduce product reliability and yield. Therefore, reduced or unmanned production is a necessary measure.

In this context, how can semiconductor factories effectively manage and maintain equipment?

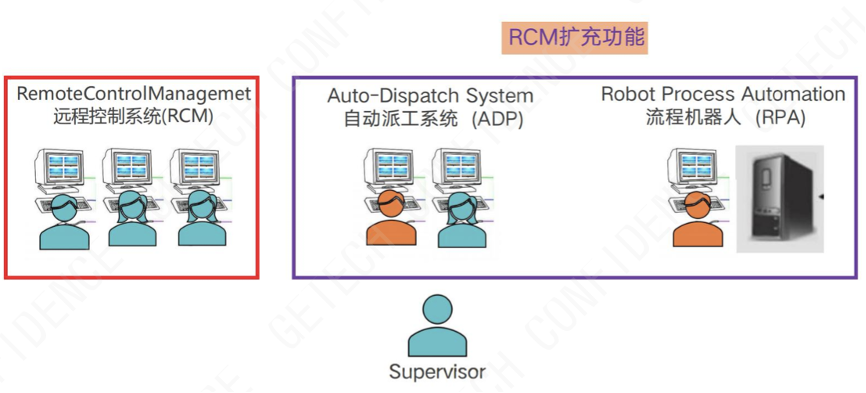

GeChuang DongZhi recognized customers' need for achieving unmanned factories and improving equipment management efficiency, thus developing the RCM Equipment Remote Control Management System. Through the RCM system, staff can directly operate multiple devices from a centralized control room, saving time spent on entering and exiting clean rooms, greatly improving equipment utilization rate.

What is the principle of the RCM Semiconductor Equipment Remote Control Management System

The working principle of GeChuang DongZhi's RCM system is as follows:

1. After connecting the semiconductor production equipment industrial computer to the controller, the controller is linked to the KVM-over-IP management host.

2. Production management computers are centralized in a control room outside the clean production area. Via standard TCP/IP network, the KVM-over-IP management host transmits control signals from the equipment industrial computers to the large screen in the control room. Production managers can connect more industrial computers or management hosts as needed, all connections made through Ethernet and IP networks. With secure and controllable authorization, operators can log in to production management computers for control.

3. The RCM system integrates with production line automation systems through open API interfaces for seamless operation.

Note:

l Ethernet IP network should not be directly connected to equipment to avoid equipment poisoning.

l Supports data transmission via communication protocols like Webservice/WCF/Socket/Http.

l Combined with expansion solutions like ADP intelligent dispatching and RPA intelligent operation, improves equipment efficiency and reduces operation wait time.

The RCM Equipment Remote Control Management System not only enables real-time acquisition of equipment dynamic data, detection of data changes, and real-time control of production equipment, but also saves factories significant manpower and resources—originally requiring multiple or dozens of workers, now only a few or even one can complete the same production tasks, greatly benefiting production efficiency.

To learn more about GeChuang DongZhi's RCM Equipment Remote Control System products/solutions, please call 400-600-2869 (same as WeChat), and our professional team will tailor a专属方案 for you.