Billion-Dollar Industrial Projects Accelerate! Guangdong Speeds Up Building an Innovation Hub for Integrated Circuit Industry

Billion-dollar industrial projects such as the 12-inch analog specialty process production line for integrated circuits (Phase III) by Yuexin Semiconductor and the third-generation semiconductor industrialization base by Shenzhen Founder Microelectronics are accelerating, driving the clustering of upstream and downstream industries... Guangdong is speeding up the creation of a globally competitive innovation hub for the integrated circuit industry. On April 18, the 25th China Integrated Circuit Manufacturing Annual Conference and Supply Chain Innovation Development Conference kicked off in Guangzhou. Industry professionals from the integrated circuit sector gathered in Guangzhou to explore development trends in the new cycle of the semiconductor industry.

At the conference, Jin Shenghong, Chairman of Guangdong Finance Holdings, revealed that the second phase of the Guangdong Semiconductor and Integrated Circuit Industry Investment Fund is in preparation, with a scale of 30 billion yuan and a fund term of up to 17 years. The mother fund can invest directly in companies, while sub-funds include themes such as automotive chips, semiconductor materials and equipment, and compound semiconductors. Moreover, 60% of the investment returns from the second-phase fund can be conceded to invested enterprises after exit to support their growth and strengthening.

Guangdong Province's Integrated Circuit Industry Fund Phase II in Preparation

In Guangzhou Huangpu, the Phase I and II projects of Yuexin Semiconductor, with a cumulative investment of 14 billion yuan, have reached full production. The Phase III project, with an investment of 16.25 billion yuan, is under construction, with two floors of the factory building taking shape and expected to be completed and operational by 2024. Yuexin Semiconductor's Phase III project has entered a new track, targeting the空白领域 of industrial and automotive electronics, focusing on the precision of chip quality specifications.

"Driven by Yuexin Semiconductor, nearly 150 upstream and downstream semiconductor companies have come to select sites, with 95 already signed and settled, gradually forming an ecosystem of the semiconductor industry chain," said Wu Yongjun, Vice President of Yuexin Semiconductor.

The establishment and mass production of Yuexin Semiconductor mark an important milestone in Guangdong's path to strengthening its 'chip' capabilities. It fills the gap in Guangzhou's chip manufacturing, bringing the only mass-produced 12-inch wafer production line in the Guangdong-Hong Kong-Macao Greater Bay Area and quickly driving the aggregation of semiconductor industry chain elements.

In the recently announced Guangdong Province 2023 Key Construction Project Plan, over 50 projects are related to the semiconductor industry, covering third-generation semiconductors, packaging and testing, semiconductor materials, MLCC, sensors, and other fields. These include the new project for a 12-inch advanced MEMS sensor and specialty process wafer manufacturing mass production line by Guangzhou Zengxin Technology Co., Ltd., the 12-inch analog specialty process production line for integrated circuits (Phase III) by Yuexin Semiconductor, and the third-generation semiconductor industrialization base construction project by Shenzhen Founder Microelectronics, among other billion-dollar projects.

In recent years, Guangdong has been focusing on building China's third pole for integrated circuits and addressing shortcomings in the industry chain. Behind the落地 of core projects and the完善 of the industry chain, policy, technology, and capital are all essential.

Among these, the Guangdong Integrated Circuit Industry Fund is a provincial government investment fund established to implement the 'Strong Core Project,' initiated and managed by Guangdong Finance Investment Holdings Co., Ltd. The first phase of the fund, with a scale of 20 billion yuan, was established in December 2020, focusing on investing in and supporting major projects in Guangdong and specialized, sophisticated, distinctive, and innovative enterprises.

At the conference, Jin Shenghong disclosed the latest progress of the fund: "The first phase of the fund has now reached 31 billion yuan, operating under a mother-sub fund structure for investments. The mother fund conducts strategic investments, mainly supporting key semiconductor enterprises in the province. At the sub-fund level, we collaborate with three investment institutions—Walden International, SummitView Capital, and China IC Capital—to jointly build Guangdong's semiconductor investment ecosystem."

"The mother fund has been investing for two years, and the sub-funds for one and a half years. We have invested in 102 projects with over 9 billion yuan, covering 45 chip design companies, 19 manufacturing and packaging/testing companies, and 38 equipment and materials companies, striving to build a semiconductor industry cluster of 'chain leaders + specialized, sophisticated, distinctive, and innovative enterprises.' Currently, two invested companies have passed IPO reviews, and 19 more will apply for IPOs this year and next," Jin Shenghong stated.

Facing complex and severe domestic and international situations and the deepening evolution of a new round of technological revolution, Jin Shenghong believes that China's integrated circuit industry development更需要 long-term stable support from government-guided funds. Therefore, building on the first phase of the integrated circuit fund, Guangdong is乘势而上, preparing to establish a second-phase fund with a scale of 30 billion yuan.

The second-phase fund will延续 the characteristics of the first phase. On one hand, investments will be diversified. For example, the mother fund can invest directly in projects, focusing on strategic industrial projects within the province and major projects introduced from outside. To leverage more social capital, a certain number of professional sub-funds will be established to invest in a batch of small and medium-sized projects.

On the other hand, the fund term is long. The second-phase fund can have a term of up to 17 years, truly leveraging the advantages of long-term capital to accompany enterprises through industry cycle fluctuations and achieve long-term stable development. Additionally, the profit concession mechanism is flexible. "When the fund exits investments, 60% of the investment returns can be conceded to the invested enterprises to support their strengthening and growth," Jin Shenghong said.

New Opportunities from New Energy Industry Development

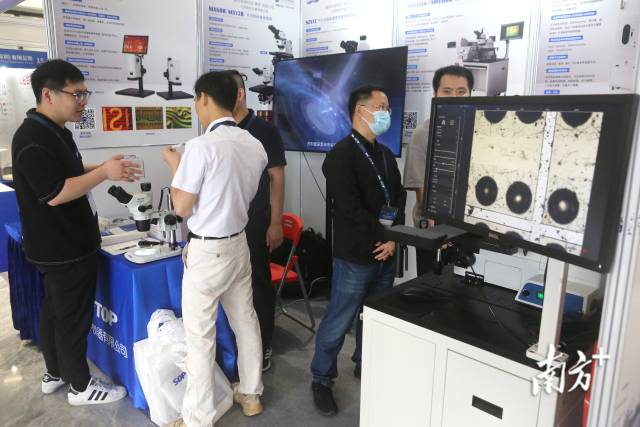

Smart cities, 5G IoT, virtual reality... these futuristic scenes full of technological sense离不开 the support of integrated circuits. Meanwhile, intelligence and digitization are also empowering the integrated circuit industry.

Reporters saw outside the venue robotic arms moving up and down,配合 mobile robots transporting materials. The materials in the dark boxes are precisely 12-inch wafers. On-site staff from YouiBot told reporters that during the production and transportation of integrated circuits, conditions such as cleanliness and transport stability are extremely demanding, which also催生 the need for digital and intelligent upgrades.

Taking smart logistics as an example, Zhao Wanqiu, Co-founder and Product Director of YouiBot, explained that in semiconductor production, the vibration value during robot搬运 by YouiBot has been reduced to as low as 0.025G, meeting the highest Class-1 cleanroom standards. This enables automatic transfer of wafer boxes between machines, electronic racks, storage warehouses, and other processes, while ensuring full-process traceability of material data.

As a national cross-industry platform originating from semiconductor manufacturing, GTRONTEC East Intelligence, through the application of the latest AI, IoT, and big data technologies, has implemented its intelligent CIM solutions for semiconductor factories in multiple facilities, helping manufacturing plants improve product yield, quality, and production efficiency.

In the view of relevant personnel at GTRONTEC East Intelligence, to accelerate the construction of smart semiconductor factories in China, domestic enterprises should strengthen independent R&D in key areas such as semiconductor equipment, EDA software, and CIM software, improving the autonomy and controllability of the entire industry chain. Especially in industrial software R&D, it is necessary to persist in combining technological innovation with production scenarios, with semiconductor manufacturing enterprises at the core and industrial software enterprises as the ecosystem, jointly developing world-class domestic industrial software. Additionally, it is essential to cultivate a group of innovative复合型人才 who understand both semiconductors and information technology, continuously enhancing the core competitiveness of domestic industrial software and providing sustained technical support for smart semiconductor factories.

The industrial transformation brought by new energy also presents further development opportunities for the semiconductor industry.

"Under the transformation of the new energy system, the power semiconductor market size will significantly benefit from the vigorous development of the new energy industry, photovoltaics, energy storage, wind power, and electric vehicles, with broad application prospects," shared Li Hong, President of China Resources Microelectronics Limited, at the conference. Semiconductor enterprises should pay attention to the opportunities brought by new energy and digital development. With the increase in localization rates, this will bring significant growth opportunities for enterprises.

In recent years, the automotive industry has been continuously moving towards electrification, connectivity, and intelligence. "Under the wave of intelligence and electrification, the industry chain is undergoing restructuring, bringing many opportunities for domestic substitution. Compared to traditional fuel vehicles, electric vehicles will新增大量电能转化需求, thereby driving demand for related power semiconductors," Li Hong said.

Leveraging China's Market Advantages to Reshape the Global Industry Chain

"The integrated circuit industry has formed a highly globalized system, with various countries and regions each having their characteristics. Over the past 20 years, China has embraced high-speed development opportunities while integrating into the international cycle, but also formed high dependencies on industry models and technological paths," said Ye Tianchun, Chairman of the Integrated Circuit Branch of the China Semiconductor Industry Association, Vice Chairman and Secretary-General of the China Integrated Circuit Innovation Alliance, and Chief Technology Officer of the National Science and Technology Major Project 02 Special, at the conference.

However, China has recognized this issue. Over the past 15 years, China has formulated policies such as major special projects, the Big Fund, and the STAR Market to guide the integrated circuit industry in building a relatively complete system layout and comprehensive capabilities, achieving significant progress in various segments of the industry chain, including product design, manufacturing processes, equipment and materials, and packaging integration.

"Our next phase of development is not blindly chasing technology from 28nm to 14nm to 7nm." Addressing the current situation faced by China's integrated circuit industry, Ye Tianchun proposed implementing a new strategy: "Establish an internal cycle, guide a dual循环, and reshape the international integrated circuit循环体系."

Ye Tianchun believes that after 15 years of 'from scratch' industry chain layout, China needs an 'upgraded development strategy' to promote solving market product supply issues. The next phase's strategy is 'product-centered, industry solution-driven,' promoting the integrated development of system applications, design, manufacturing, and equipment materials. In this transformation process, it is essential to leverage the advantages of China's market崛起 more, leading the global market with the Chinese market, opening new tracks, forming an 'internal cycle + dual循环,' and reshaping the global industry chain.

"Currently, China is in a critical period of a new round of technological revolution, industrial transformation, and enhancement of industry and supply chain levels, with rapid development in networking, digitization, and intelligence. Various new paths that do not rely on尺寸微缩 are increasingly becoming new driving forces for integrated circuit development, bringing new markets and spaces for integrated circuits," said Wei Shaojun, Chairman of the Design Branch of the China Semiconductor Industry Association, Executive Vice Chairman of the China Integrated Circuit Innovation Alliance, and Chief Technology Officer of the National Science and Technology Major Project 01 Special.

In Wei Shaojun's view, the globalization of the semiconductor industry chain has promoted changes in the semiconductor industry model, strengthening division of labor and cooperation in various segments while gradually weakening the connection between design and process. While striving to maintain the integrity of the current global semiconductor supply chain, it is necessary to build a robust local semiconductor supply chain. Besides the localization of equipment and materials, strengthening design-process coordination is an important task for enhancing supply chain security.

"It is essential to strengthen design-process coordination. Chip design companies need to make up for their lack of process knowledge, and chip manufacturing needs to transition from a 'production-centered' model to a 'product-centered' model," Wei Shaojun believes. If transitioning to a 'product-centered' model, chip design enterprises would focus not on customers but on customers' products; they would care not only about their own capabilities but also about whether their capabilities can be integrated with those of their customers.

"The combination of these two generates a全新的合作模式: customers rely on a customized PDK (Process Design Kit) produced through collaboration, which has the advantage of fully utilizing the极限水平 of chip manufacturing processes," Wei Shaojun said.

[Reporter] Chang Daoli, Xu Ningning, Liu Shan

[Photographer] Liu Liqin