GTRONTEC AIoT Platform Empowers Digital Transformation in Manufacturing

Recently, the 2023 6th Greater Bay Area ICT Conference and High-Quality Development Conference for the Software Industry was held in Guangdong. Key and emerging enterprises, as well as experts and scholars in the software field, gathered to discuss innovation trends in the Greater Bay Area software industry, industrial foundational software, software industry chains, and software project investment, promoting new patterns, advantages, and ecosystems for software industry development.

Yan Shaolin, Digital Solutions Director of GTRONTEC, was invited to attend and delivered a keynote speech titled 'AIoT Platform Empowers High-Quality Digital Transformation in Manufacturing,' sharing practical applications of AIoT technology in smart manufacturing.

In his speech, Yan Shaolin pointed out that technological means and digital thinking are playing an increasingly important role in factory production and operations. At the same time, traditional industrial collaboration models are changing: previously centered around legal entities with one-to-one single-point coordination, enterprise decisions relied heavily on managers' capabilities and experience. AIoT, combined with technologies like the Industrial Internet, is redefining industrial collaboration by collecting, processing, and analyzing vast amounts of production and equipment data for manufacturing. The richer and more open the data, the higher the efficiency of industrial chain collaboration.

Technological Leadership

Dongzhi Platform Provides Solid Technical Support for Manufacturing

Currently, with the accelerated integration of emerging technologies such as digital twins, 5G, IoT, and AI into industries, AIoT-driven digital transformation and innovation in manufacturing are imperative. As a national-level cross-industry platform incubated from the semiconductor industry, GTRONTEC possesses strong platform technology capabilities, mature smart factory planning expertise, and extensive experience in building benchmark cases, having successfully served nearly 20,000 clients across more than 20 industries.

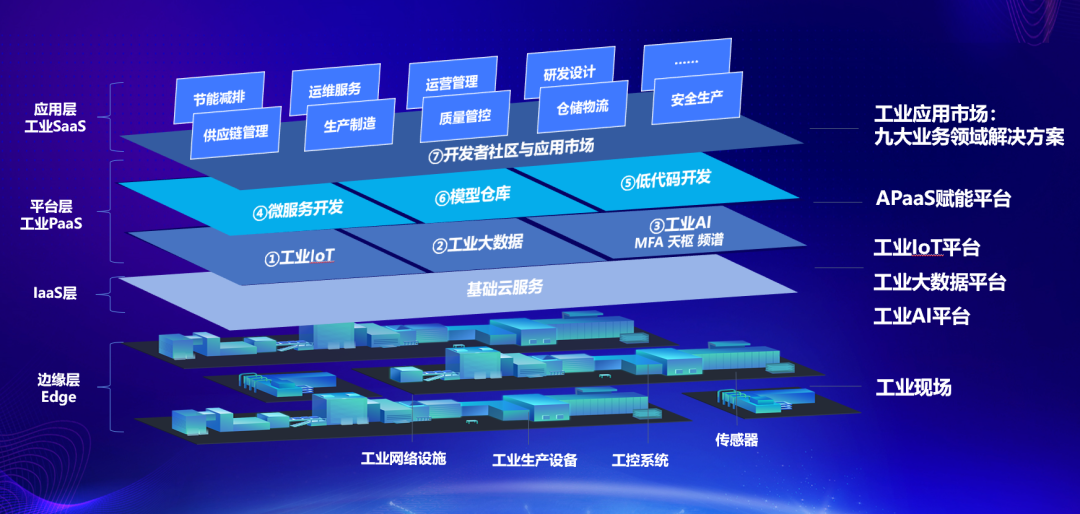

The Dongzhi Industrial Application Intelligence Platform (hereinafter referred to as the 'Dongzhi Platform'), independently developed by GTRONTEC, connects sensors, industrial control systems, facilities, and equipment on the factory floor. Leveraging the following three core enabling technologies, it integrates upper-layer industrial applications to build digital solutions covering the entire value chain:

Industrial IoT Platform: An efficient and reliable industrial IoT system. Supports millions of data connections and real-time computing, enabling visualization and intelligent analysis; cloud-edge collaboration supports thousands of cloud acquisition protocols.

Industrial Big Data Platform: Drives the transformation from data to data assets. Provides platform-based, componentized data capabilities, offering enterprises rapid decision-making responses and detailed operational analysis, making data actionable, avoiding 'data silos,' improving operational efficiency, and better driving business development and innovation.

Industrial AI Platform: Comprehensive AI analysis for various data types, continuously upgrading factory data analysis capabilities. Tools such as Multi-Factor Analysis (MFA) and Tianshu AI Visual Inspection help enterprises quickly build AI capabilities.

Industry Benchmark

GTRONTEC Creates Best Practices for AIoT Empowerment in Manufacturing

GTRONTEC focuses on application scenarios such as quality control, energy and carbon management, production management, and operational management, integrating IT, OT, and DT to achieve cross-industry, cross-domain, and cross-regional empowerment, covering continuous, discrete, and hybrid manufacturing models.

For example, in digital quality management, GTRONTEC's QMS Quality Management System enables full lifecycle quality management for groups and products. Through data collection and entry, it deeply mines and summarizes originally discrete and implicit quality data, providing effective data support for quality control throughout the product lifecycle. Additionally, GTRONTEC offers a complete product and service matrix, including MFA Multi-Factor Analysis, visual inspection solutions like ADC, and more, helping manufacturing effectively enhance quality management through integrated one-stop digital solutions.

In digital energy and carbon management, GTRONTEC's dual-carbon platform integrates equipment IoT, AI algorithms, and edge control to form a cloud-edge integrated operating system. Leveraging device connectivity, big data processing, and AI modeling capabilities, it combines massive data沉淀 with equipment mechanisms and algorithms to form industrial dual-carbon know-how models, achieving organic integration of energy low-carbon and industry, fully leveraging digitalization's key role in achieving 'dual-carbon' goals, and maximizing enterprise energy and carbon benefits.